As a key piece of equipment in the production of corrugated cardboard, the single facer machine has become an indispensable tool for manufacturers aiming to enhance their quality control processes and deliver top - notch products to the market.

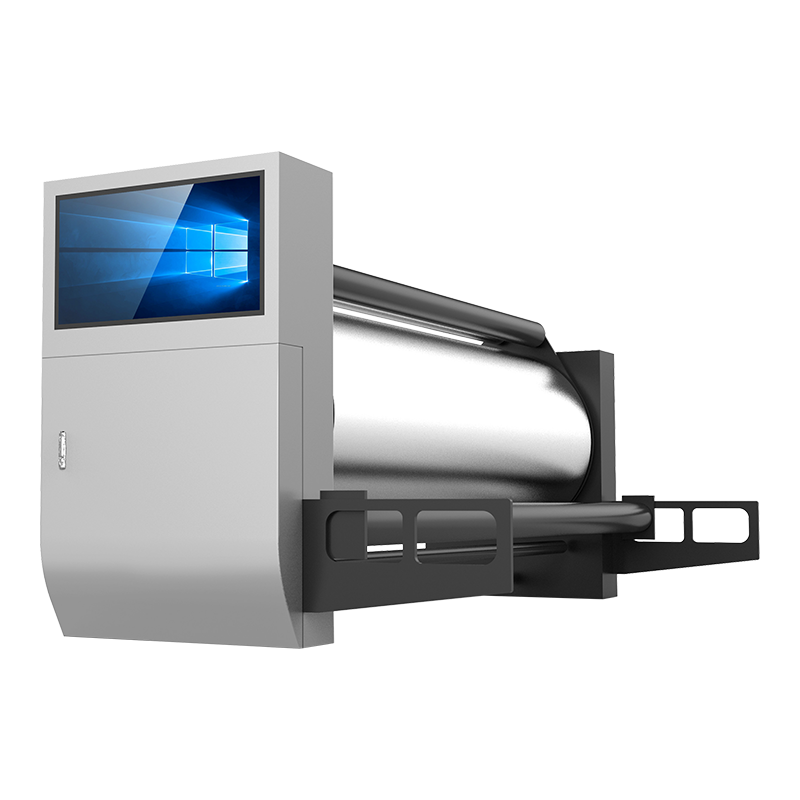

The single facer machine, specifically the cassette single facer model, has revolutionized the way corrugated cardboard is produced. Unlike traditional methods that often involved multiple steps and manual adjustments, the cassette single facer offers a more streamlined and automated approach. This not only increases production speed but also significantly improves the consistency and quality of the corrugated cardboard.

One of notable advantages of the single facer corrugation machine is its ability to maintain precise control over the corrugation process. The machine's advanced technology allows for accurate flute formation, ensuring that each corrugated sheet meets the required specifications. This level of precision is crucial in industries such as packaging, where the strength and durability of the cardboard are directly related to the quality of the corrugation.

Moreover, the single facer machine is equipped with state - of - the - art sensors and monitoring systems that continuously check the quality of the corrugated cardboard as it is being produced. These systems can detect even the slightest deviations from the set parameters, allowing for immediate adjustments to be made. This real - time quality control ensures that every sheet of corrugated cardboard that comes off the machine meets high standards, reducing the risk of defects and waste.

Another significant benefit of the single facer corrugation machine is its versatility. The cassette single facer, in particular, can easily switch between different flute sizes and paper types. This flexibility allows manufacturers to produce a wide range of corrugated cardboard products to meet the diverse needs of their customers. Whether it's a lightweight box for shipping small items or a heavy - duty container for industrial use, the single facer machine can handle it all.

In addition to its quality control and versatility, the single facer machine also offers significant cost - saving benefits. By automating the corrugation process and reducing the need for manual labor, manufacturers can lower their production costs while increasing their output. This makes the single facer machine an attractive investment for companies looking to improve their competitiveness in the market.

Furthermore, the single facer corrugation machine is designed with sustainability in mind. It uses less energy compared to older, less efficient machines, and it produces less waste due to its precise control over the corrugation process. In an industry that is increasingly focused on environmental responsibility, the single facer machine helps manufacturers meet their sustainability goals while still delivering high - quality products.

As the packaging industry continues to evolve, the importance of the single facer machine will only grow. Manufacturers who invest in this advanced technology will find themselves better equipped to meet the demands of their customers and stay ahead of the competition. The single facer corrugation machine, with its precision, versatility, cost - effectiveness, and sustainability, is truly a game - changer in the world of corrugated cardboard production.

The single facer corrugation machine, especially the cassette single facer model, has proven to be a valuable asset in enhancing quality control in the production of corrugated cardboard. Its ability to maintain precise control over the corrugation process, coupled with its real - time monitoring systems, ensures that every sheet of corrugated cardboard meets high standards of quality. With its versatility, cost - saving benefits, and sustainability features, the single facer machine is set to play a crucial role in the future of the packaging industry.

English

English  Español

Español  Português

Português  عربى

عربى