In the packaging industry, the choice of raw materials can significantly impact the efficiency, cost, and sustainability of packaging solutions. Among these materials, corrugated board rolls and traditional paper rolls play distinct roles. These machines play a crucial role in streamlining production processes and reducing operational costs, making them an essential component of modern packaging operations.

Sturdiness and Structure

Corrugated board rolls are known for their outstanding strength and structural integrity compared to traditional paper rolls. The unique corrugated pattern in corrugated board rolls provides a level of rigidity that is essential for protecting fragile items during transportation. In contrast, traditional paper rolls, lacking this corrugated structure, offer less protection and are more susceptible to damage.

Material Composition

The composition of corrugated board rolls sets them apart from carton box rolls. Corrugated board rolls consist of a fluted paper layer sandwiched between two flat layers of linerboard, creating a three-layer structure. This contrasts with carton box rolls, which are typically single-layered and do not have the same level of structural support.

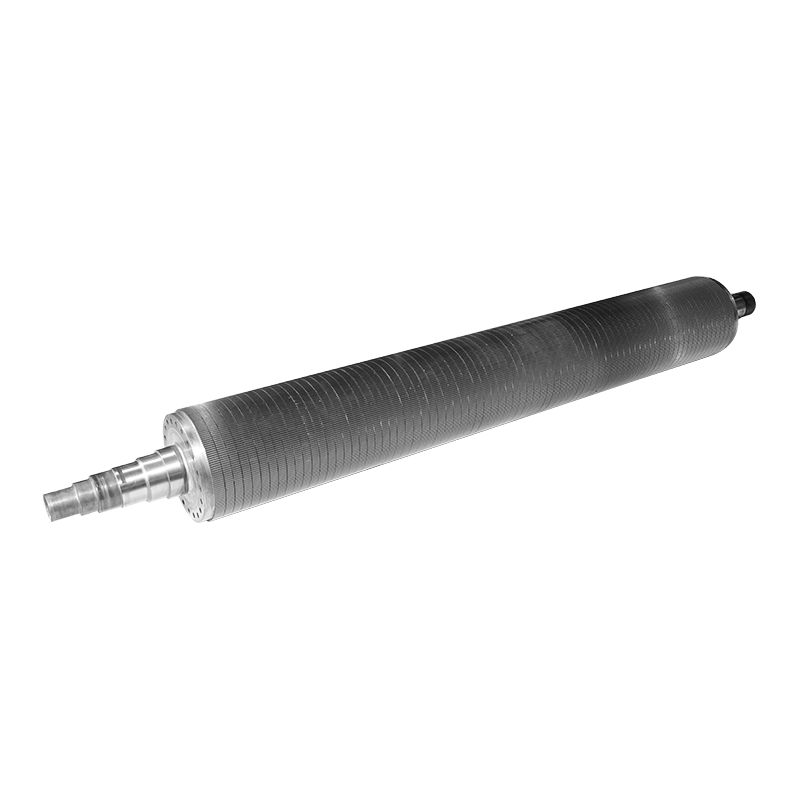

Manufacturing Process

The manufacturing process of corrugated carton rolls is more intricate than that of traditional paper rolls. Corrugated carton rolls undergo a process where the fluted paper is glued to the linerboard, creating a strong and lightweight material. This process is more complex than simply rolling out paper, as seen with traditional paper rolls.

Environmental Impact

Corrugated board rolls are often more environmentally friendly than carton box rolls. The fluting process in corrugated board rolls uses less material than the single-layered construction of carton box rolls, making them a more sustainable choice. Additionally, corrugated board rolls are recyclable, which contributes to a circular economy and reduces waste.

Cost-Effectiveness

The cost-effectiveness of corrugated board rolls is another area where they differ from traditional paper rolls. While traditional paper rolls may be cheaper to produce, the durability and recyclability of corrugated board rolls can cause lower overall costs in the long run due to reduced damage and waste.

Customization and Flexibility

Corrugated board rolls offer greater customization options compared to carton box rolls. The ability to adjust the flute size and the number of plies in corrugated board rolls allows for a tailored approach to packaging design. This flexibility is not as readily available with carton box rolls, which are limited by their single-layer construction.

Application in Packaging

When it comes to application in packaging, corrugated board rolls are the preferred choice for heavy-duty packaging due to their strength. Corrugated carton rolls, with their multi-ply structure, are ideal for creating box structures that can hold significant weight. Traditional paper rolls, on the other hand, are better suited for lighter items or as a component in composite materials.

Corrugated board rolls, carton box rolls, and corrugated carton rolls each have their unique characteristics that make them suitable for different packaging applications. Corrugated board rolls stand out for their strength, environmental benefits, and customization options, offering a robust solution for a wide range of packaging needs. Understanding these differences is crucial for businesses looking to optimize their packaging strategies and meet the evolving demands of consumers and the environment.

English

English  Español

Español  Português

Português  عربى

عربى