The packaging industry plays a crucial role in the global supply chain, ensuring products are safely transported, stored, and delivered to customers. Among the various types of packaging solutions, corrugated boxes have emerged as a popular choice due to their durability, versatility, and cost-effectiveness. To meet the growing demand for these boxes, the packaging industry has seen the rise of advanced corrugated box making machinery that significantly increases efficiency and productivity in production.

Revolutionizing Production with Advanced Machinery

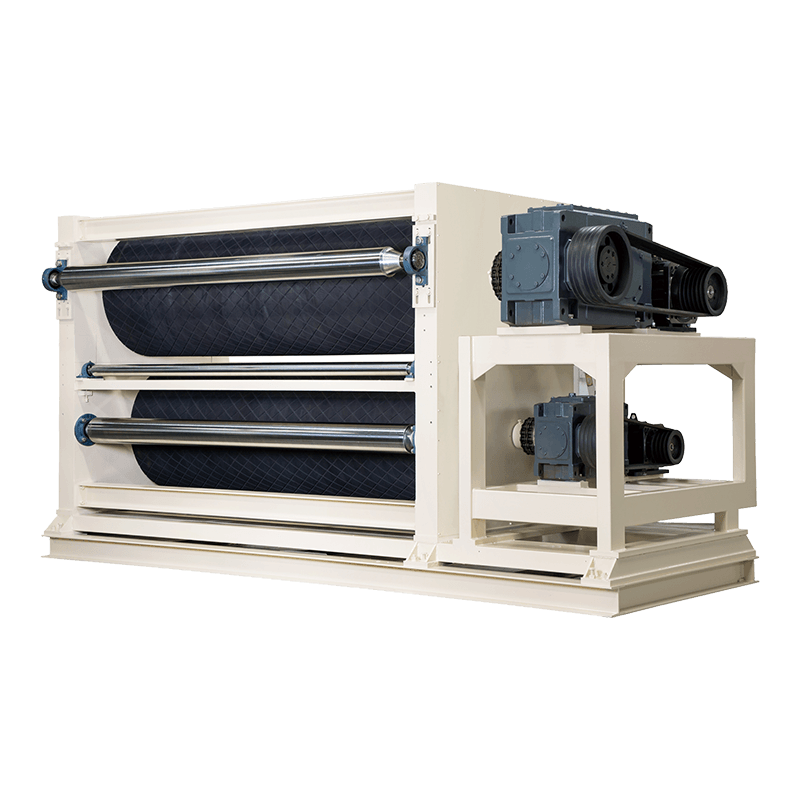

The traditional method of manufacturing corrugated boxes involved a considerable amount of manual labor, slow processes, and higher chances of error. However, with the advent of modern corrugated box making machinery, manufacturers have streamlined production processes, allowing for faster and more accurate box creation. These machines integrate various functions, such as the cutting, folding, and gluing of corrugated board, all within a single system. This automation reduces human intervention, increases output, and ensures a higher level of consistency in the final product.

Optimizing the Corrugated Box Parts Production

The corrugated box parts include the fluted medium, liners, and glue that are essential to creating the final packaging solution. By using automated machinery, manufacturers can precisely control the production of each part. The corrugated box making machinery has become more sophisticated, enabling the precise alignment of the fluted medium with the liners, which is crucial for ensuring the box's strength and durability. This precise control also helps minimize waste, ensuring that raw materials are used efficiently, further reducing costs and environmental impact.

The ability to produce uniform and consistent corrugated box parts with automated equipment ensures that the boxes meet high-quality standards every time. As a result, the likelihood of defects such as misaligned seams or weak joints is significantly minimized, cause fewer product returns or customer complaints. This consistency is essential in industries where packaging integrity is paramount, such as food, electronics, and pharmaceuticals.

Enhanced Flexibility in Design and Production

One of the key benefits of modern corrugated box making machinery is its ability to offer flexibility in design and production. With the increasing demand for customized packaging solutions, manufacturers need machines capable of producing different box shapes, sizes, and designs on the same production line. Advanced machinery allows manufacturers to switch between various designs with minimal downtime, accommodating the diverse needs of customers.

This flexibility is particularly valuable in industries that require specialized packaging, such as for fragile items or products with unique dimensions. Additionally, the machines can quickly adjust to different print requirements, further enhancing the efficiency of the packaging process.

Streamlining the Corrugated Box Printing Process

The corrugated box printing process is another area where advancements in machinery have led to significant improvements. Previously, printing on corrugated boxes was time-consuming and required multiple steps. Now, automated machines integrate the printing process directly into the production line, streamlining the entire process. With the help of advanced digital and flexographic printing technologies, manufacturers can achieve high-quality prints with vivid colors and intricate designs.

The integration of printing into the production line means that there is less need for external processes, reducing guide times and enhancing efficiency. Furthermore, the automation of the corrugated box printing process allows for more consistent results, which is crucial for businesses looking to maintain their brand image on every box produced. Manufacturers can now print custom logos, product information, and other branding elements directly onto the boxes, creating a professional and polished final product.

Reducing Production Time and Costs

One of significant advantages of corrugated box making machinery is its ability to reduce production time. With automated processes, tasks that once took hours or even days to complete manually are now finished in a fraction of the time. The machines can run continuously, ensuring a consistent output that meets demand without sacrificing quality.

This reduction in production time directly correlates to a decrease in operational costs. Fewer workers are needed to operate the machines, and the automation of repetitive tasks means less human error. Furthermore, the efficient use of raw materials reduces waste, which contributes to cost savings for manufacturers.

English

English  Español

Español  Português

Português  عربى

عربى