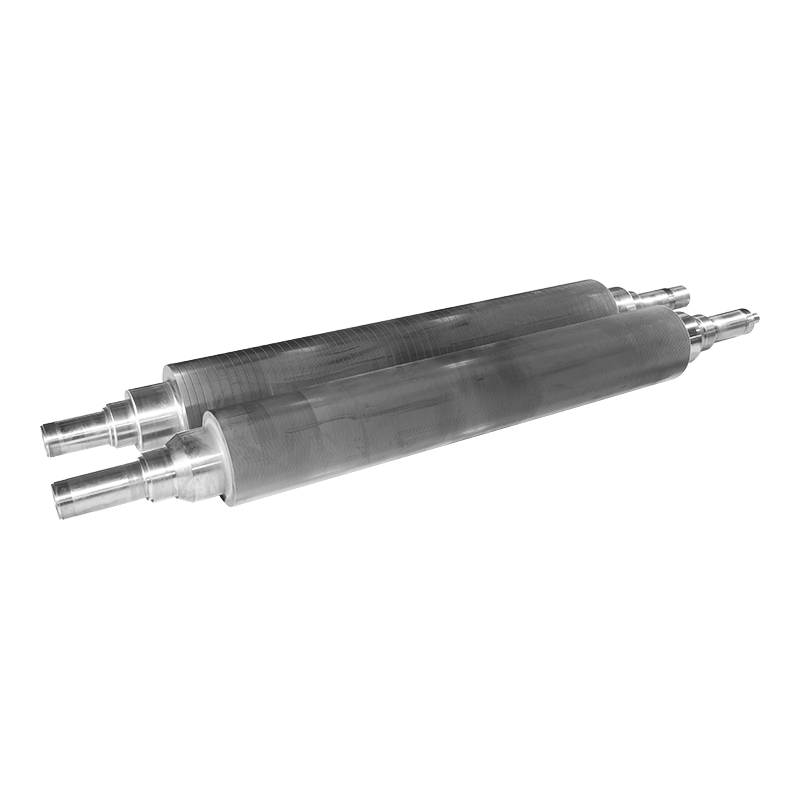

A corrugated roller supplier plays a significant role in the overall efficiency of packaging production. Corrugated rollers are essential components in the manufacturing process of corrugated cardboard, which is widely used in packaging. The performance of these rollers directly influences the quality of the corrugated board and the speed of the production line. Understanding the impact of a reliable corrugated roller supplier can help businesses maintain smooth operations and produce packaging materials that meet market demands.

One of the primary contributions of a corrugated roller supplier is ensuring the availability of high-quality rollers that meet specific technical requirements. Corrugated rollers must be manufactured with precise dimensions and material specifications to maintain consistent flute formation and adhesive application. A corrugated roller supplier who provides durable and accurately engineered rollers helps reduce production defects, such as improper flute profiles or uneven corrugation. This reliability minimizes waste and decreases the need for rework, improving packaging efficiency.

In addition to supplying rollers, a corrugated roller supplier often offers valuable technical support and advice. They can assist packaging manufacturers in selecting the right rollers for different types of corrugated boards, including single-wall or double-wall configurations. By understanding the production process and the machinery involved, the supplier can recommend rollers with appropriate flute sizes and surface treatments. This guidance ensures compatibility with the production line and helps maintain consistent board quality, which is crucial for downstream packaging operations.

The ability to customize rollers is another important aspect of the supplier's role. Different packaging applications may require variations in roller design to achieve desired results. A corrugated roller supplier that offers customization services can produce rollers tailored to the specific needs of a manufacturer, such as varying flute profiles, surface coatings, or hardness levels. Customized rollers can improve adhesion and reduce wear, causing longer service life and fewer interruptions. This adaptability contributes to sustained production efficiency and cost control.

Timely delivery is also a critical factor that a corrugated roller supplier influences. Corrugated manufacturing plants often operate with tight schedules, and any delay in receiving replacement rollers can cause costly downtime. A supplier with dependable production and logistics capabilities ensures that replacement rollers are delivered promptly, minimizing interruptions. Consistent supply from a reliable supplier enables manufacturers to plan maintenance and roller changes without affecting overall production flow.

Moreover, a corrugated roller supplier may provide after-sales services such as roller maintenance, repair, or regrinding. These services extend the lifespan of rollers and maintain their performance over time. Proper maintenance support reduces the frequency of complete replacements, which lowers operational costs and environmental impact. By assisting in upkeep, the supplier helps maintain consistent packaging quality and production speeds.

A strong partnership with a corrugated roller supplier also allows for innovation and continuous improvement. As packaging demands evolve, manufacturers may require rollers with improved materials or surface technologies to meet new standards or reduce costs. A responsive supplier can collaborate on developing enhanced rollers that improve corrugation performance or reduce energy consumption during production. This cooperative approach supports packaging efficiency and competitiveness.

A corrugated roller supplier plays a crucial role in packaging efficiency by providing high-quality, customized rollers, offering technical support, ensuring timely delivery, and supporting maintenance. Their involvement helps manufacturers achieve consistent product quality, minimize waste, and reduce downtime. By working closely with a reliable corrugated roller supplier, packaging producers can enhance operational efficiency and meet the evolving needs of the market.

English

English  Español

Español  Português

Português  عربى

عربى