We use premium-grade 50CrMoA roll material, supporting high-speed production.Our corrugating roll operating speed can exceed 350 m/min.

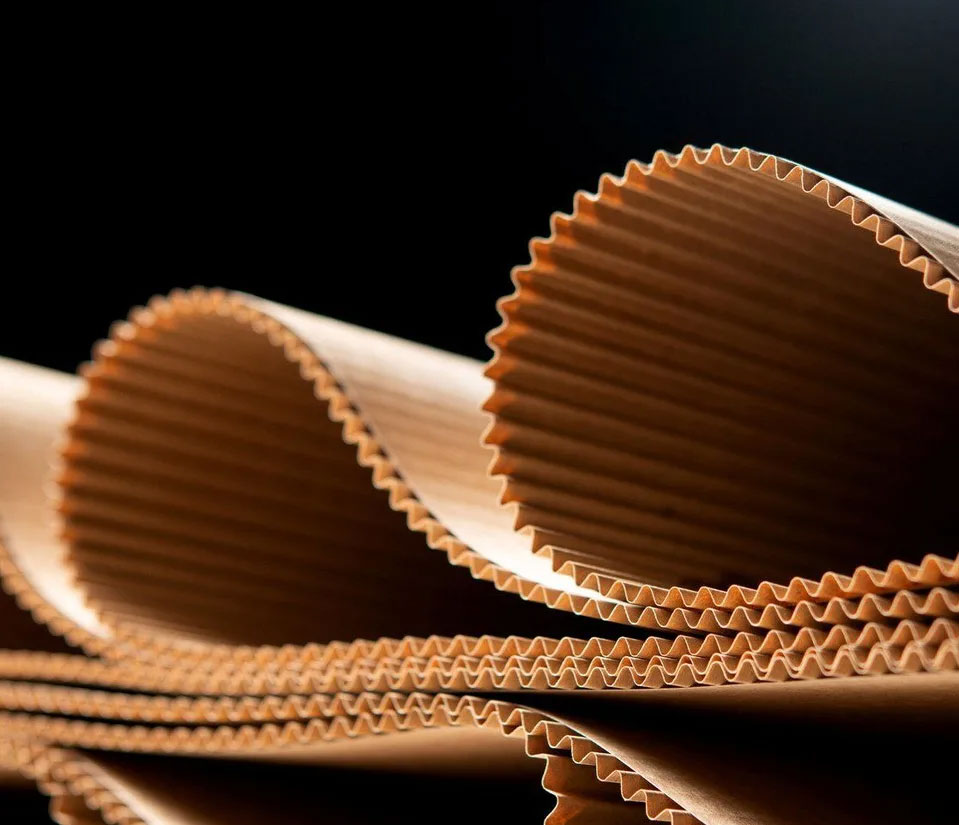

With over 20 years of experience in corrugation pattern design, our designed corrugating rolls have the same flute height and pitch as others, but with a material consumption rate that is 1%-0.5% lower than the industry standard.This does not compromise the physical properties of the corrugated cardboard, helping customers save on raw paper costs.

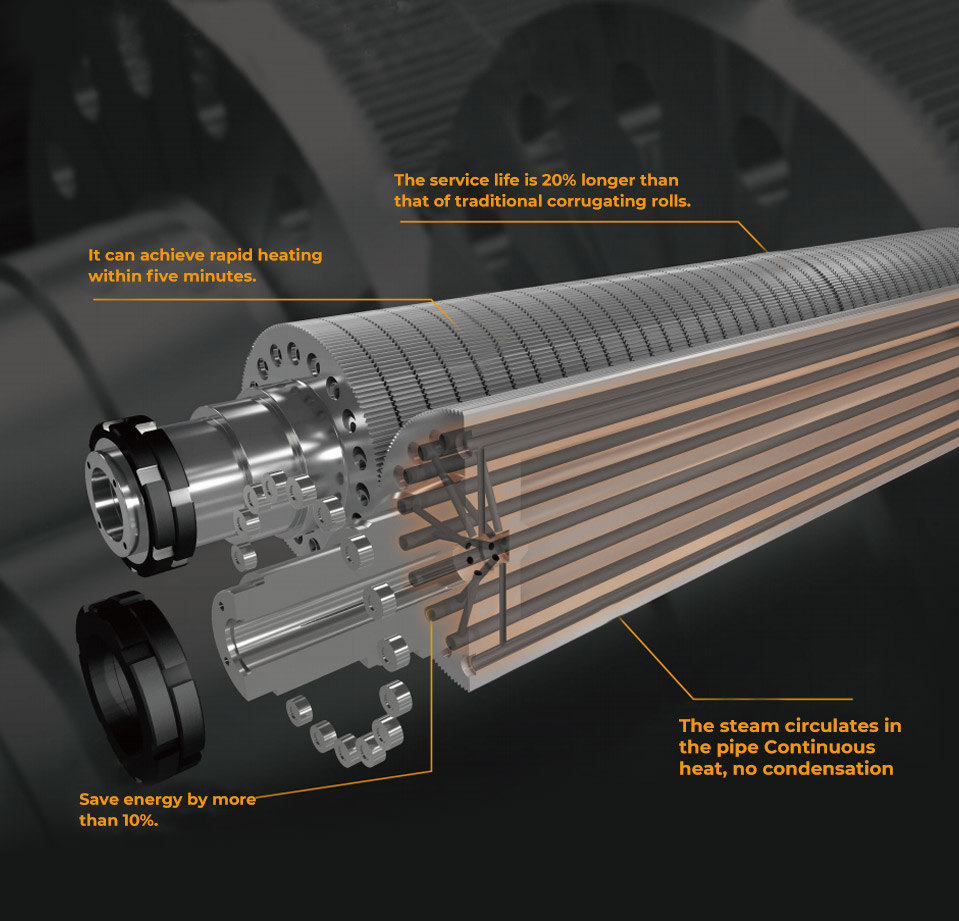

Our exclusive composite heat treatment process includes surface processing, compound nitriding, tempering, deep cryogenic treatment, and other multi-step processes to maximize surface hardness. The microstructure after heat treatment is more refined, with hardness reaching HRC ≥60. The service life is exceptionally long; the peripheral heating corrugating rolls have a lifespan exceeding 100 million meters.

We use the ultra-high-speed tungsten carbide spraying equipment and Praxair 1342 ultra-hard tungsten carbide powder from Praxair USA. This significantly reduces porosity and corrosion. We use high-precision Siemens CNC grinding machines to ensure the high precision of the corrugating rolls.

Our unique polishing technology achieves a surface roughness of Ra0.2-0.4. A silicon oil coating is applied to the surface to effectively prevent pitting corrosion and rust.

We have full-process manufacturing capabilities and follow strict manufacturing and quality inspection procedures. This guarantees delivery of our products.