One such solution that has gained significant attention is the double sided glue tape roller. This innovative tool has proven to be a game - changer in various industries, offering a quick, clean, and effective way to bond materials together. From furniture making to electronics assembly, the double sided glue tape roller has found its place as a versatile and indispensable piece of equipment.

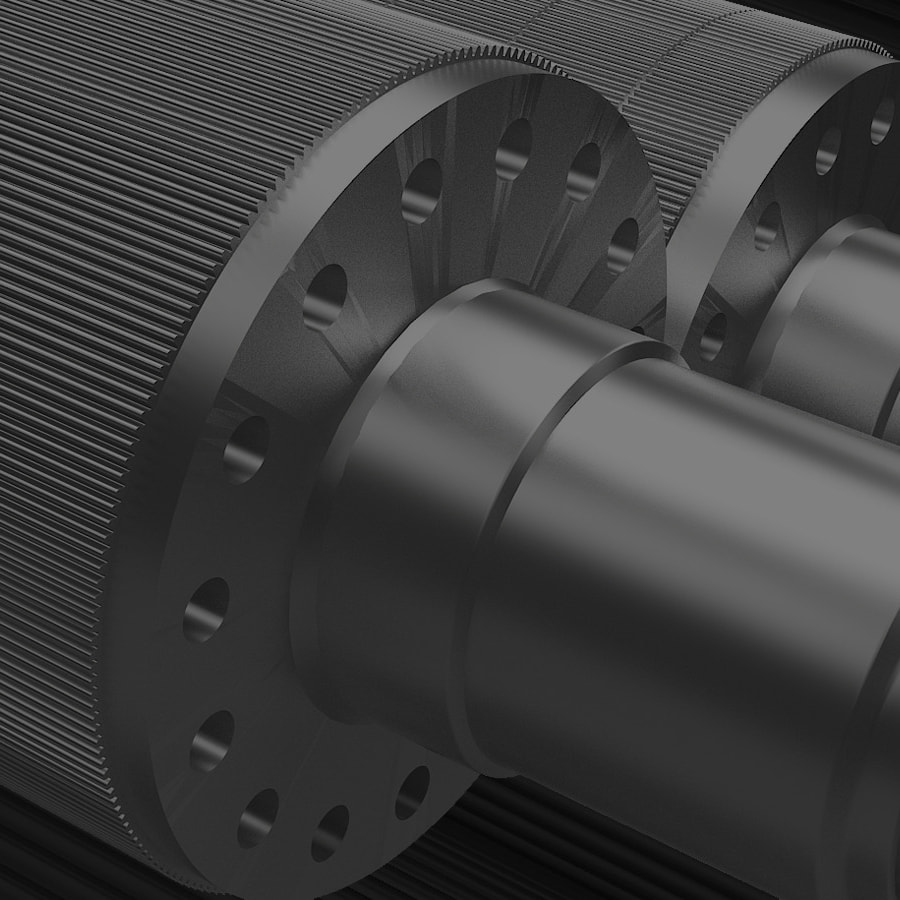

At the heart of this technology lies the stick it glue roller. This simple - yet powerful - device is designed to apply adhesive tape with precision and ease. The stick it glue roller is engineered to ensure that the adhesive is evenly distributed, providing a strong and consistent bond. Whether it's bonding thin veneers in furniture production or attaching components in electronics, the stick it glue roller delivers reliable results every time.

One of the key applications of the double sided glue tape roller is in the furniture industry. Here, the veneer glue roller plays a crucial role in the production process. Veneers, which are thin slices of wood used to cover furniture, require a delicate and precise bonding method. The veneer glue roller, with its ability to apply adhesive tape evenly, ensures that the veneers are securely attached to the furniture surface. This not only enhances the aesthetic appeal of the furniture but also increases its durability.

The double sided glue tape roller is also highly valued in the electronics industry. In this sector, precision is of very importance. The stick it glue roller is used to attach small components and parts with accuracy. The double - sided adhesive tape ensures that these components are held firmly in place, reducing the risk of movement or detachment. This is particularly important in the production of delicate electronic devices, where even the slightest misalignment can cause malfunction.

Another advantage of the double sided glue tape roller is its efficiency. Unlike traditional bonding methods, which often require drying or curing times, the double sided glue tape roller provides an instant bond. This means that production processes can be completed more quickly, increasing overall productivity. The stick it glue roller is designed to work seamlessly with various types of adhesive tapes, allowing manufacturers to choose suitable option for their specific needs.

In addition to its efficiency, the double sided glue tape roller is also user - friendly. The veneer glue roller, for example, is easy to operate and requires minimal training. This makes it accessible to a wide range of users, from small - scale furniture makers to large - scale electronics manufacturers. The double sided glue tape roller is also designed to be durable and long - lasting, ensuring that it can withstand the demands of a busy production environment.

Moreover, the double sided glue tape roller offers a clean bonding solution. Unlike some adhesives that can leave residues or require messy application methods, the stick it glue roller applies the adhesive tape cleanly and neatly. This not only results in a more aesthetically pleasing finish but also reduces the risk of contamination or damage to the materials being bonded.

The double sided glue tape roller, with its stick it glue roller and veneer glue roller components, has proven to be an efficient and reliable bonding solution across various industries. Its ability to provide a strong, consistent, and instant bond makes it a valuable tool for manufacturers looking to improve their production processes. Whether it's in furniture making or electronics assembly, the double sided glue tape roller offers a clean, user - friendly, and efficient way to bond materials together. As technology continues to advance, the double sided glue tape roller is set to play an increasingly important role in the world of manufacturing and assembly.

English

English  Español

Español  Português

Português  عربى

عربى