More Information About Glue Rollers What You Need to Know

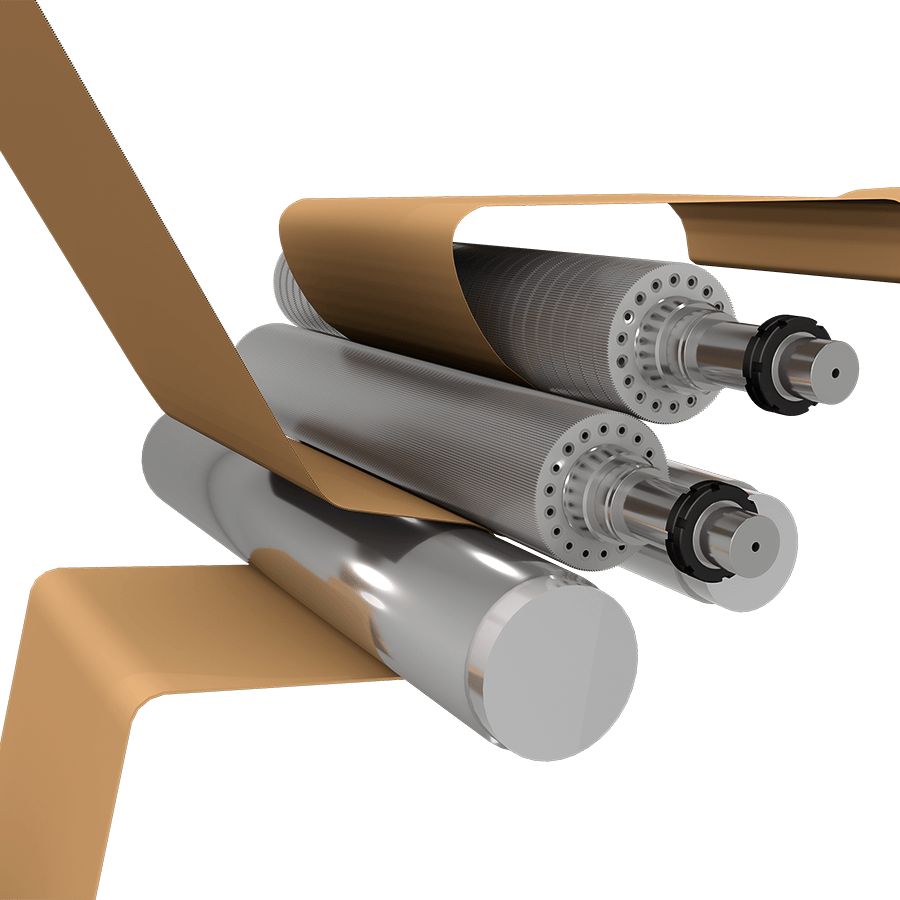

As a professional Chinese manufacturer of pressure rolls and corrugating machinery components, Zhejiang Yonghui Roller Co., Ltd. specializes in high-performance Glue Rolls (also known as glue pasting rollers or glue spreader rollers) that ensure good adhesive transfer in corrugated board production. Our expertise in precision engineering and advanced material science allows us to deliver rollers that enhance bonding strength, reduce glue consumption, and minimize downtime.

Why Choose Yonghui Glue Rollers?

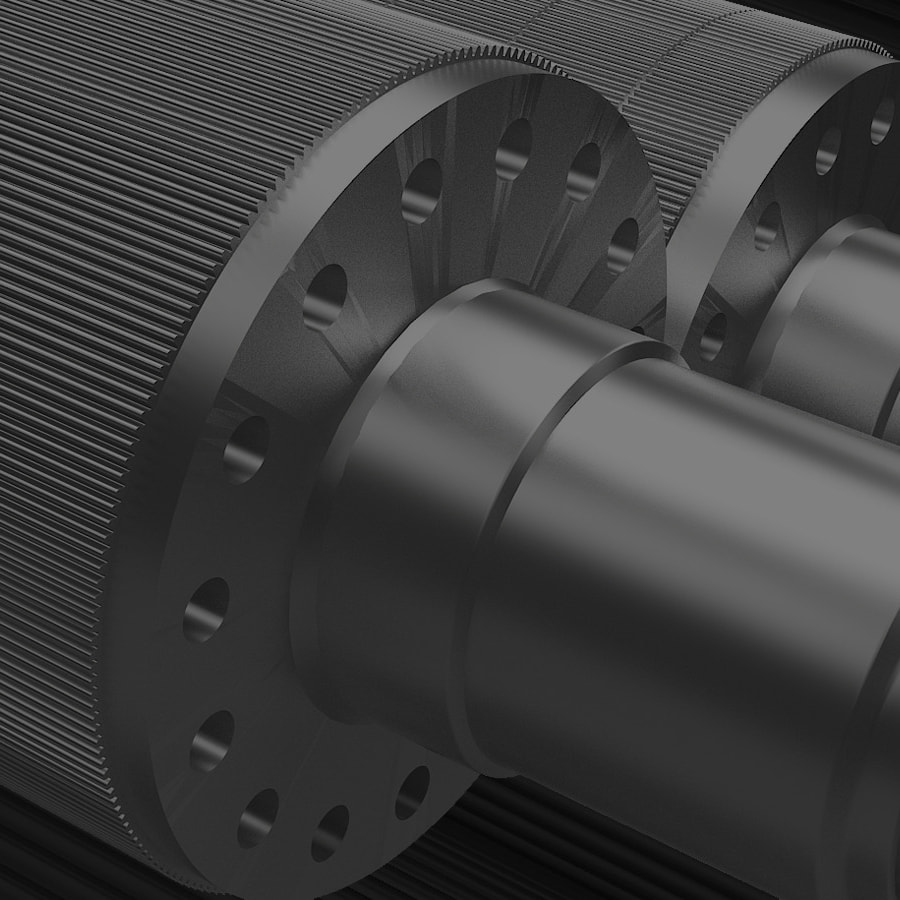

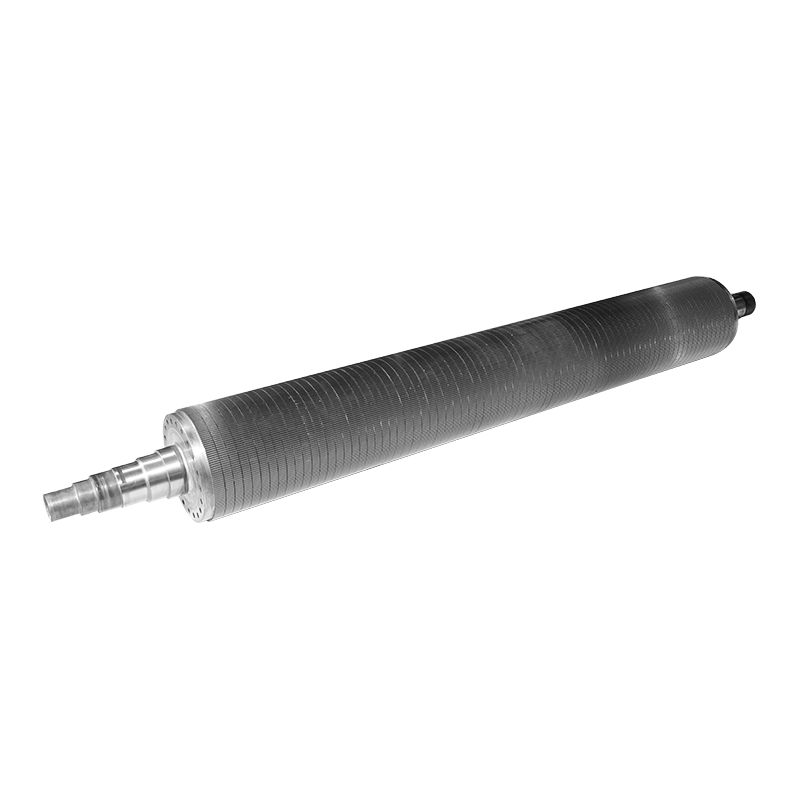

1. outstanding Construction for Consistent Glue Application

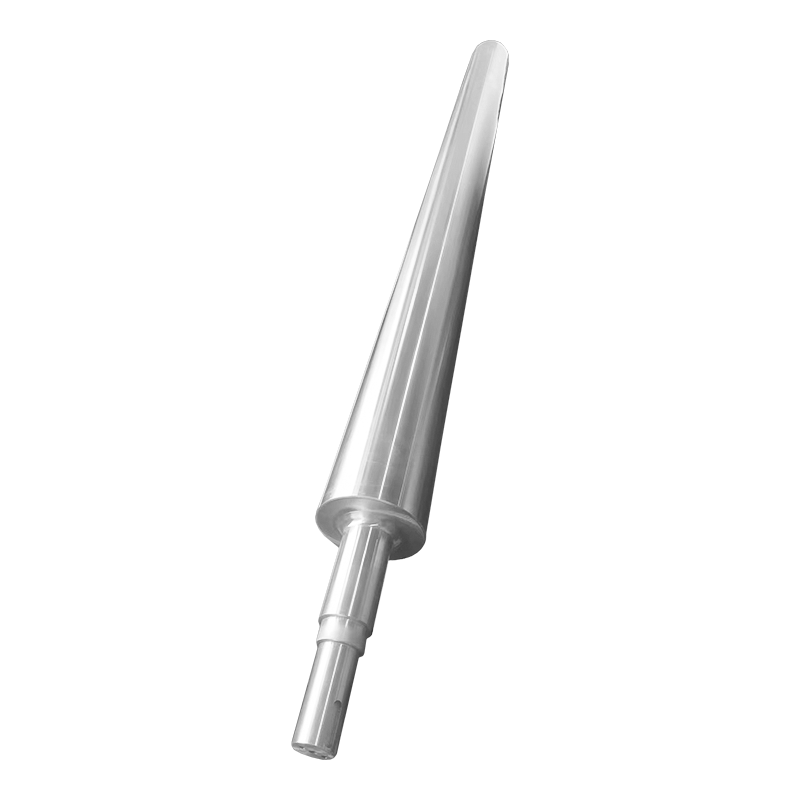

Our glue spreader rollers are crafted from high-grade alloy steel with a mirror-polished chromium or carbide-coated surface, ensuring:

Uniform glue distribution – Prevents streaks or dry spots in the corrugated medium.

Precise glue film thickness – Adjustable for different paper weights (100–400 gsm).

Corrosion resistance – Withstands water-based and starch-based adhesives.

2. Engineered for High-Speed Corrugators

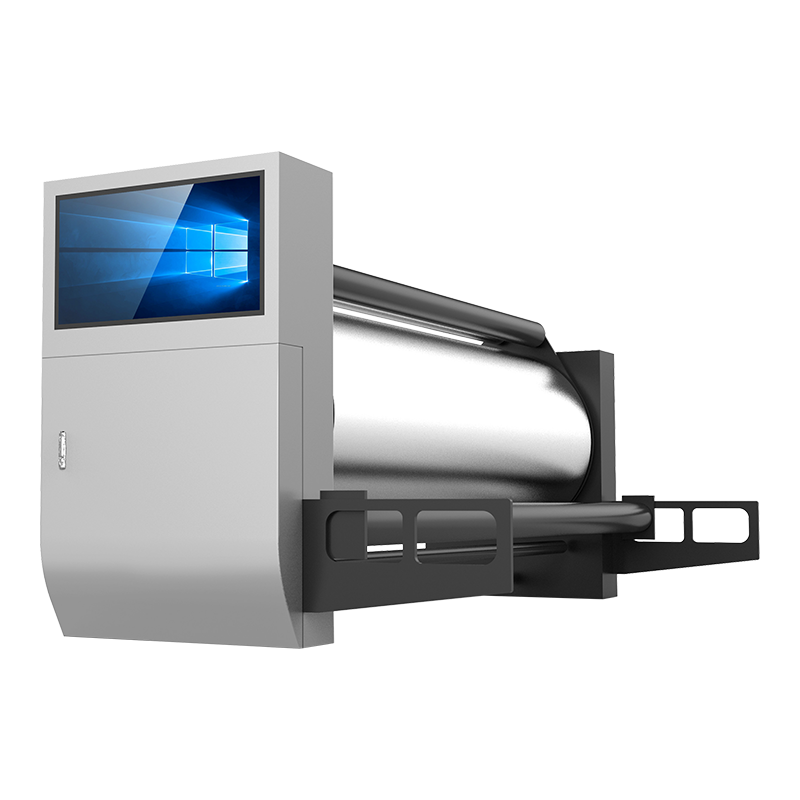

Compatible with modern corrugators running at 300+ meters/minute, our glue pasting rollers feature:

- Dynamic balancing (G2.5 standard) to prevent vibration at high RPM.

- Quick-release mechanisms for fast replacement during production changes.

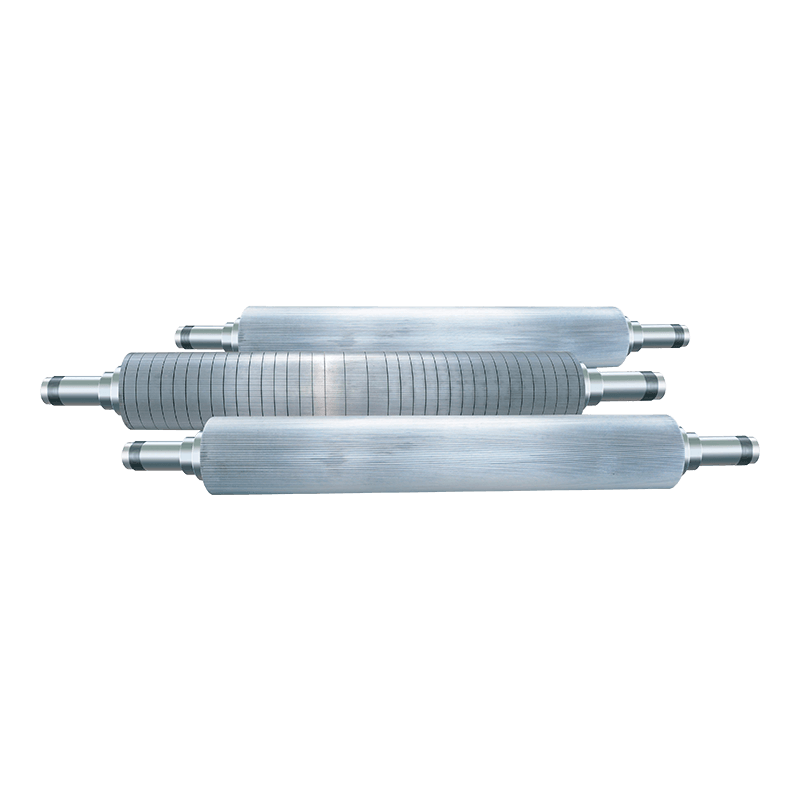

3. Custom Solutions for Diverse Needs

We offer tailored Glue Rolls for specific applications:

- Single-Facer Glue Rollers – Optimized for A/B/C flute profiles.

- Double-Backer Glue Rollers – Designed for heavy-duty liner bonding.

- Narrow-Width Rollers – For specialty boxes (e.g., electronics packaging).

Key Advantages Over Competitors

① Extended Service Life

Our glue spreader rollers undergo deep cryogenic treatment and ultra-hard coating, lasting 2–3x longer than standard rollers before refurbishment.

② Energy & Glue Savings

The ultra-smooth surface reduces adhesive cling, cutting glue usage by 15–20% while maintaining bond strength.

③ Easy Maintenance

- Anti-stick coatings minimize glue buildup.

- Modular designs allow partial replacement of worn sections.

Who Benefits from Yonghui Glue Rollers?

Corrugated Sheet Plants

Ensures consistent glue penetration for high crush resistance in shipping boxes.

Recycled Paper Processors

Our carbide-coated glue pasting rollers resist abrasion from coarse recycled fibers.

High-Speed Packaging Mills

Reduces defects like starved joints or glue flooding, improving box quality.

Technical Specifications

Feature Specification

Material: Alloy steel + Chrome/Carbide coating

Hardness: 60–65 HRC (Carbide version)

Max. Operating Speed: 500 m/min

Diameter Tolerance: ±0.02mm

Get Your Custom Glue Roller Solution

Zhejiang Yonghui provides:

Free technical consultations to match the right roller to your production line.

OEM-friendly designs (custom lengths, coatings, and grooves).

Global shipping with after-sales support.

The Glue Roll plays a critical and indispensable role in the corrugated cardboard production process. Specifically engineered to apply adhesive with high precision to the surface of the medium or linerboard, this component directly influences the strength, quality, and integrity of the finished corrugated board. Our Glue Roll is manufactured using premium-grade materials that ensure superior wear resistance, corrosion resistance, and long-term durability, even under high-speed and continuous operating conditions.

Thanks to its advanced surface treatment and finely machined structure, the Glue Roll provides uniform and controlled glue application, ensuring every section of the substrate receives just the right amount of adhesive. This results in stronger bonding between the fluted medium and the liner, leading to enhanced product strength and improved load-bearing capacity for packaging applications. Consistent glue application also minimizes the risk of delamination or weak bonding, which can compromise the performance of the final packaging product.

Engineered for high performance in demanding production environments, this roll functions flawlessly within modern corrugated board production lines, where efficiency and precision are paramount. Its optimized glue distribution system helps reduce glue waste, contributing to both cost savings and more sustainable production practices. By minimizing excessive adhesive usage and improving accuracy, the Glue Roll also enhances product aesthetics and reduces the need for post-production corrections.

One of the standout features of our Glue Roll is its exceptional reliability during continuous, high-speed operation. Built to withstand the mechanical stresses and thermal fluctuations of industrial manufacturing, it maintains stable performance over extended periods. This means reduced machine downtime, less frequent replacement, and lower maintenance requirements, all of which are vital for maintaining productivity in high-volume packaging facilities.

Upgrade your corrugator's efficiency— Explore our Glue Roller solutions today!

English

English  Español

Español  Português

Português  عربى

عربى