The packaging industry relies heavily on efficiency and consistency to meet growing global demand. At the heart of corrugated board production lies a critical component: the Corrugating Roller. These rollers form the fluted layers that give corrugated cardboard its strength and structure. Their role goes far beyond shaping paper; they directly influence speed, durability, and overall productivity in packaging operations.

Creating Strong and Uniform Flutes

One of the main contributions of a Corrugating Roller is the formation of precise flutes. These wave-like structures provide cushioning, rigidity, and stacking strength in packaging. When rollers are manufactured with high accuracy, they produce uniform flutes that improve load-bearing capacity and reduce the risk of box deformation. Consistency in flute size also helps optimize material usage, as less paper is wasted due to defects or irregular patterns.

Supporting High-Speed Production

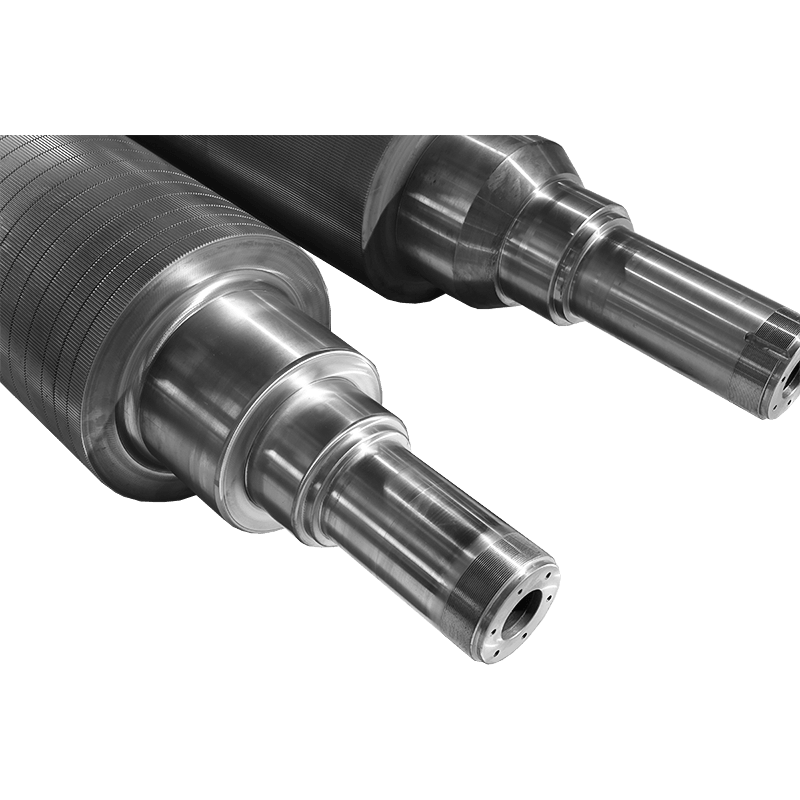

Modern packaging plants operate under tight schedules, with machines running continuously. A Corrugating Roller designed with high wear resistance and smooth surface finishing allows machines to maintain speed without frequent interruptions. Reduced friction and even pressure distribution keep paper from tearing, which minimizes downtime and keeps output steady. This efficiency has a direct effect on meeting delivery timelines and reducing overall production costs.

Extending Machine Lifespan

The condition of rollers affects not only product quality but also the lifespan of the entire corrugating machine. Rollers with precise engineering and durable coatings resist wear and surface damage over long cycles. By maintaining consistent performance, a Corrugating Roller reduces strain on other machine components, lowering the frequency of repairs. This contributes to fewer breakdowns, which helps factories maintain smoother workflows.

Enhancing Energy Efficiency

Energy consumption is a growing concern in large-scale manufacturing. Corrugating machines require significant power, but well-designed rollers can help reduce unnecessary energy use. A Corrugating Roller with a balanced profile ensures smoother paper feeding, requiring less pressure and less heat to bond layers together. This not only saves energy but also reduces operating costs, making production more sustainable.

Improving Surface Quality and Printability

In addition to strength, the surface of corrugated sheets must be suitable for printing and labeling. Rollers that maintain precise flute geometry create a smoother outer surface, which enhances print quality. For packaging companies, this detail is crucial because branding, barcodes, and product information must be clearly displayed. A well-performing Corrugating Roller ensures that the final packaging meets both structural and visual requirements.

Reducing Maintenance Interruptions

Regular maintenance can slow down productivity if machine parts wear out quickly. High-quality rollers require less frequent replacement and are easier to service when needed. Some factories use chrome-plated or tungsten-coated rollers to extend durability. With a Corrugating Roller built for resilience, maintenance intervals are longer, and the risk of unexpected shutdowns is lower. This translates into more consistent output and less downtime.

Supporting Customization in Packaging

As packaging demands diversify, factories need to produce different types of corrugated boards, from lightweight boxes to heavy-duty cartons. A Corrugating Roller with flexible design options allows plants to adjust flute sizes and combinations quickly. This adaptability helps manufacturers serve a wide range of industries—such as e-commerce, food, and electronics—without slowing down production lines.

The Corrugating Roller is a critical component that directly influences productivity in the packaging industry. From creating strong flutes and supporting high-speed production to enhancing energy efficiency and reducing maintenance, rollers help ensure that factories can deliver quality packaging consistently. By focusing on durability, precision, and adaptability, corrugating rollers continue to play a central role in keeping packaging operations efficient and reliable.

English

English  Español

Español  Português

Português  عربى

عربى