Corrugator lines play a central role in the production of corrugated cardboard, which is widely used for packaging across many industries. Over the years, advances in technology have transformed these lines, enabling manufacturers to produce higher volumes of quality board more efficiently. Understanding how modern corrugator lines improve productivity can help businesses optimize operations and meet growing demand.

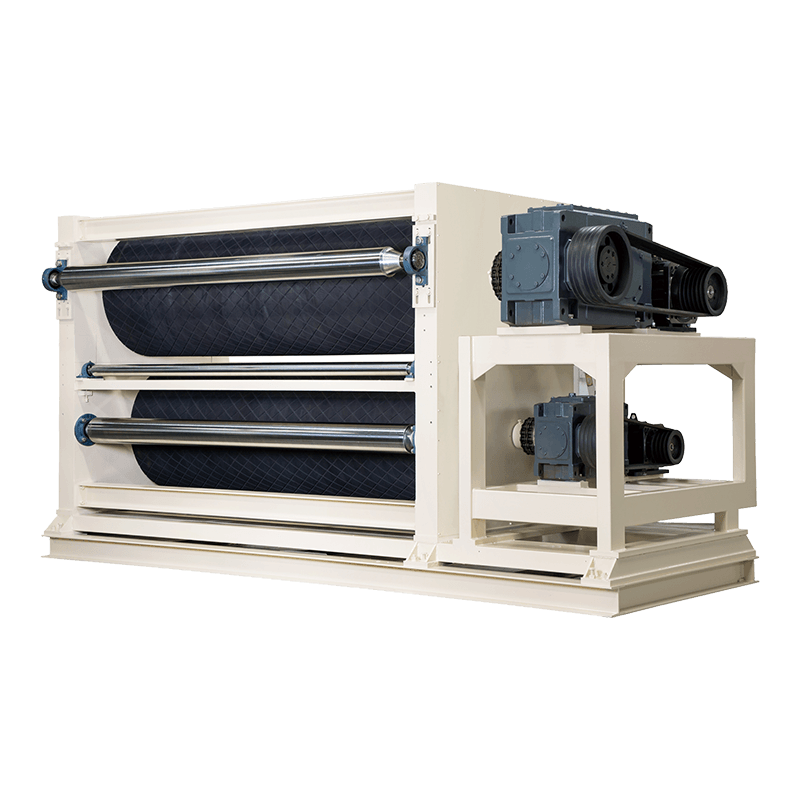

A Corrugator Line consists of several key sections, including the single facer, double backer, preheater, and cutting units. Each section contributes to the overall speed and quality of the production process. Modern lines often incorporate automated controls that adjust temperature, pressure, and speed in real time. This ensures that the corrugated board is produced consistently, reducing waste and minimizing downtime caused by manual adjustments.

One of the primary ways modern corrugator lines enhance productivity is through increased operational speed. Automated systems can maintain consistent production rates while reducing the risk of defects. High-speed motors and advanced drive mechanisms allow the line to operate continuously for extended periods without interruption. This not only improves throughput but also reduces labor requirements, as operators spend less time monitoring and adjusting the line manually.

Quality control is another important factor. Sensors and monitoring systems on modern corrugator lines detect variations in board thickness, moisture content, and alignment. These systems provide immediate feedback, allowing operators to correct issues before they affect the entire production batch. Consistent quality reduces the need for rework, which can be time-consuming and costly, and ensures that the finished products meet customer specifications.

Energy efficiency also contributes to productivity improvements. Modern corrugator lines often include heat recovery systems, optimized steam usage, and low-friction components that reduce energy consumption. By lowering operational costs while maintaining high production rates, manufacturers can achieve more output without significantly increasing resource use. In addition, automated systems can schedule maintenance during off-peak hours, minimizing production interruptions and extending the life of equipment.

Flexibility is another feature that helps modern corrugator lines improve productivity. Adjustable settings allow manufacturers to switch between different board types and thicknesses with minimal downtime. This adaptability is particularly valuable for businesses that produce a variety of packaging products or need to respond quickly to changing market demands. By reducing the time required for line changeovers, manufacturers can maintain continuous production and avoid lost output.

Integration with digital systems further enhances efficiency. Modern lines can connect to enterprise resource planning (ERP) systems, providing real-time data on production rates, material usage, and equipment performance. This visibility allows managers to make informed decisions about scheduling, inventory, and staffing, helping to optimize the entire production process.

Modern corrugator lines improve productivity through a combination of automation, quality control, energy efficiency, flexibility, and digital integration. Automated adjustments ensure consistent output, sensors reduce defects, and energy-saving measures lower operational costs. Flexible settings and data-driven management allow manufacturers to maintain high production rates while adapting to changing requirements. By adopting modern Corrugator Lines, companies can achieve smoother operations, reduced waste, and more reliable delivery of corrugated board products.

English

English  Español

Español  Português

Português  عربى

عربى