A Peripheral Heating Corrugating Roller plays a key role in corrugated board production, especially in lines that require stable flute formation and controlled bonding conditions. By applying heat evenly along the outer surface of the roller, this design supports consistent paper shaping and adhesive performance during high-speed operation.

Understanding how this type of roller works, where it is applied, and what factors affect its performance can help manufacturers improve efficiency without unnecessary complexity.

Working Principle of Peripheral Heating

Unlike internal heating structures, a Peripheral Heating Corrugating Roller focuses on heating the roller surface directly. Heat is distributed around the circumference, allowing the liner and medium to reach a stable temperature during contact. This approach reduces temperature variation across the flute profile and helps maintain uniform corrugation under continuous operation.

Peripheral heating also shortens thermal response time. Since heat transfer happens closer to the paper contact area, the system can react faster to production adjustments, such as changes in speed or paper grade.

Application in Corrugated Board Production

A Peripheral Heating Corrugating Roller is commonly used in single facer units within corrugator lines. It supports stable flute forming when processing medium paper under varying moisture and strength conditions.

In daily production, consistent heat distribution helps reduce flute deformation, uneven bonding, and surface stress on the paper. This is particularly useful when handling recycled paper or mixed fiber materials, where temperature control becomes more sensitive.

Impact on Product Quality

One practical advantage of using a Peripheral Heating Corrugating Roller is its influence on bonding reliability. Even surface temperature helps adhesive activate at the right moment, reducing risks of weak bonding or over-drying.

Stable flute height and shape also contribute to better stacking strength and dimensional consistency of finished boards. These factors are important for downstream processes such as die-cutting, printing, and folding.

Maintenance and Operational Considerations

From a maintenance perspective, a Peripheral Heating Corrugating Roller typically offers easier inspection compared to complex internal heating designs. Since heating elements are positioned closer to the surface, issues such as uneven heating or wear can be identified earlier.

Routine maintenance includes checking temperature uniformity, surface condition, and alignment. Keeping the roller surface clean and smooth helps maintain effective heat transfer and reduces paper dust buildup during long production runs.

Material and Manufacturing Factors

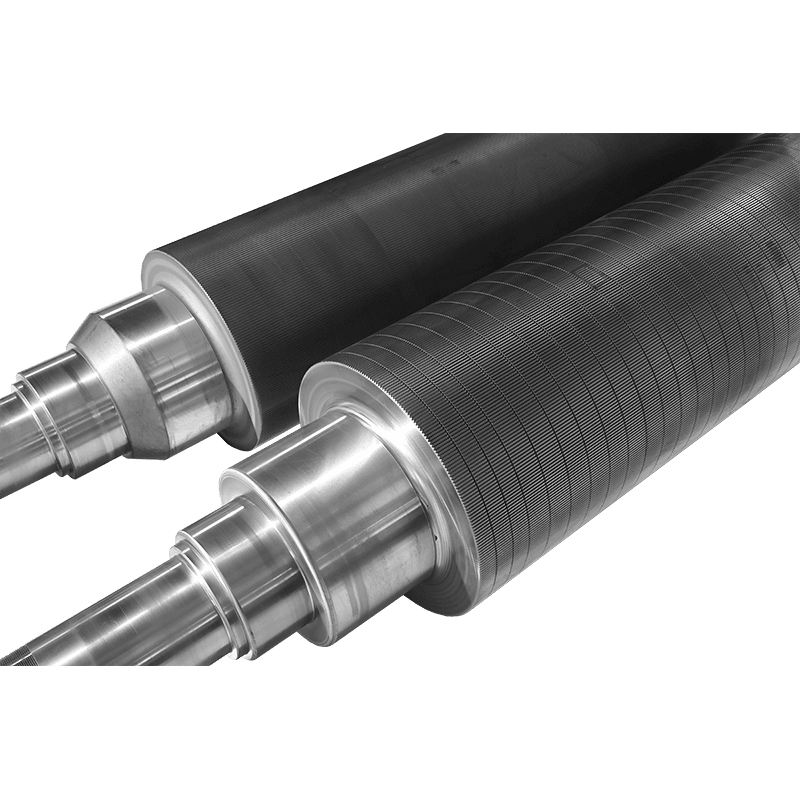

The performance of a Peripheral Heating Corrugating Roller depends on material selection and machining accuracy. Rollers are usually manufactured with wear-resistant alloys and precise flute profiles to ensure long-term dimensional stability.

Surface treatment and balancing also affect operational smoothness. Proper manufacturing control ensures that heat distribution remains stable and that the roller performs reliably under continuous load.

Selecting the Right Roller Configuration

When selecting a Peripheral Heating Corrugating Roller, manufacturers should consider flute type, production speed, paper quality, and heating control requirements. Matching the roller design to the specific corrugator setup helps avoid unnecessary adjustments during operation.

It is also important to evaluate compatibility with existing heating systems and temperature control units. A well-matched roller supports stable output while minimizing downtime and energy fluctuation.

A Peripheral Heating Corrugating Roller provides a practical solution for corrugated board manufacturers seeking stable heat control and consistent flute formation. By focusing heat delivery on the roller surface, this design supports reliable bonding, predictable paper shaping, and smoother operation. With proper selection and maintenance, it becomes a dependable component within modern corrugating systems.

English

English  Español

Español  Português

Português  عربى

عربى