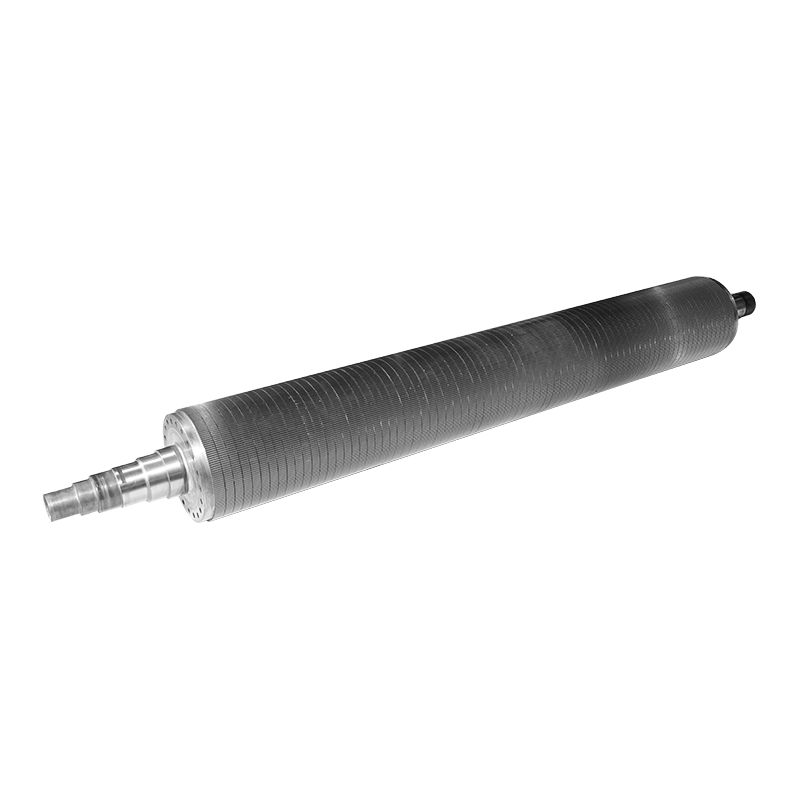

More Information About Peripheral Heating Corrugating Rolls What You Need to Know

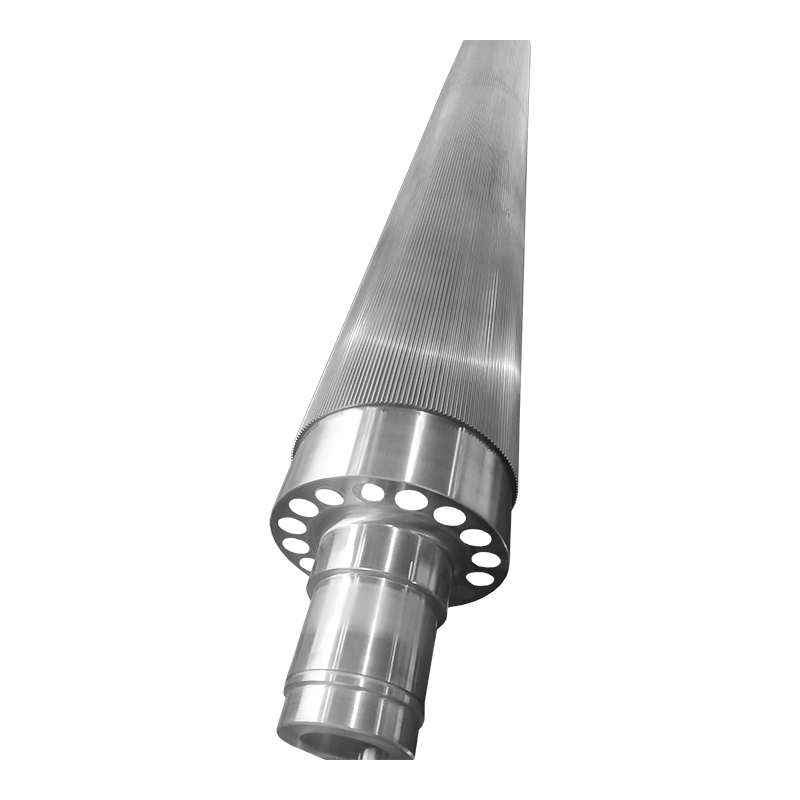

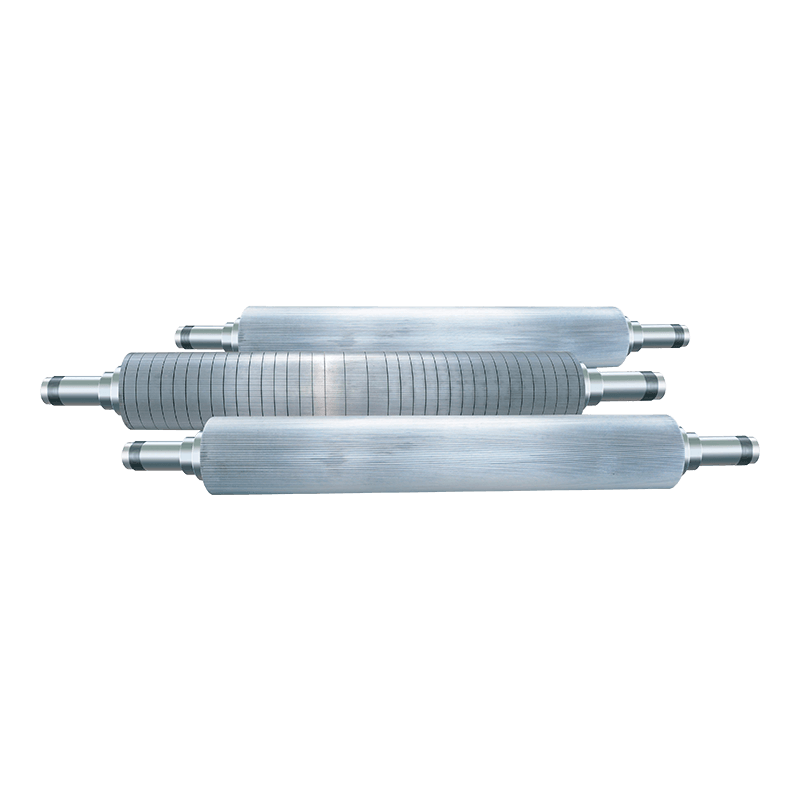

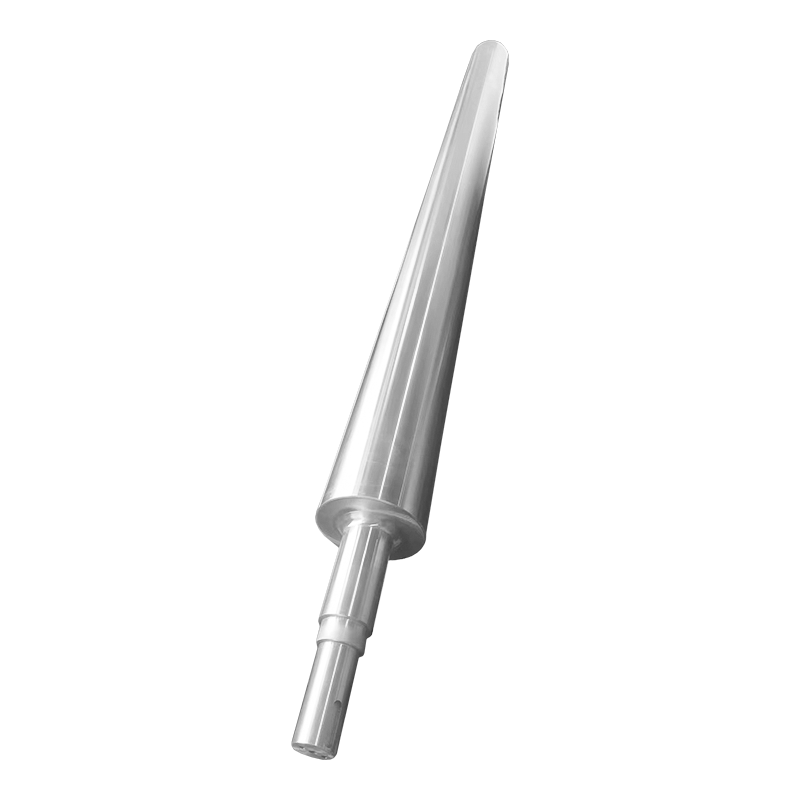

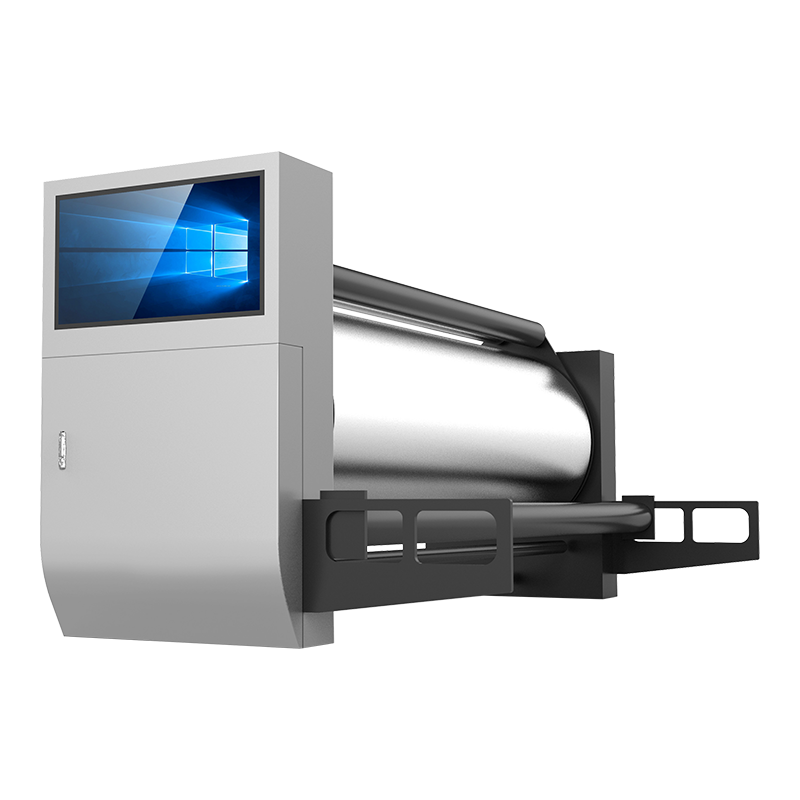

At Zhejiang Yonghui Corrugated Roller Co., Ltd., we take immense pride in our innovative and high-performance pressure rolls, specifically designed to revolutionize the corrugated cardboard production process. Our flagship product, the Peripheral Heating Corrugating Roll, stands out as a testament to our commitment to advanced and continuous improvement in the packaging industry.

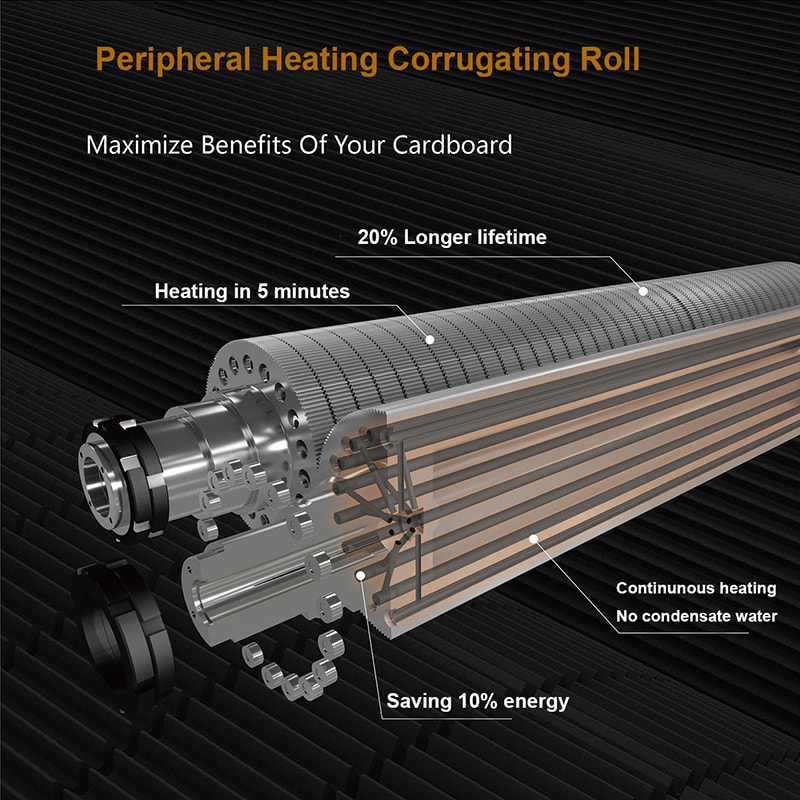

Heating Efficiency

Our Peripheral Heating Corrugating Roll is engineered to deliver rapid and uniform heating, ensuring good performance in high-speed production environments. This advanced steam heating structure allows for quick temperature adjustments and maintains a consistent temperature profile across the entire working width of the roll. This uniformity is crucial for achieving high-quality corrugated cardboard without deformations or inconsistencies.

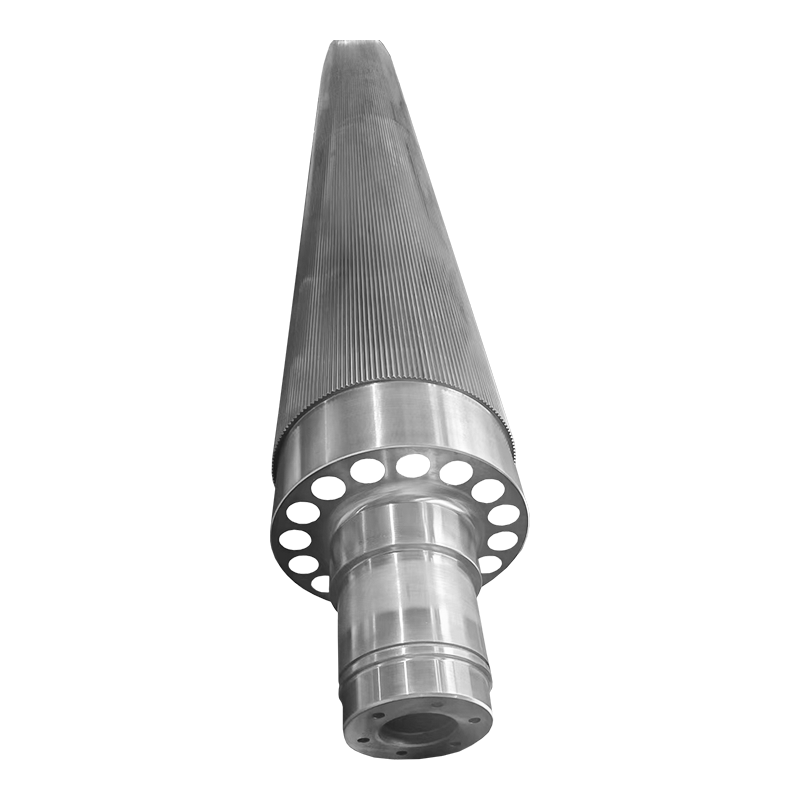

Enhanced Durability and Longevity

One of the key advantages of our Periphery Heating Flute Roller is its exceptional durability. The roll's design minimizes deformation, resulting in a service life that is 20% longer compared to traditional corrugating rolls. This extended lifespan translates to significant cost savings and reduced downtime for maintenance and replacement.

Energy Efficiency

In an era where energy conservation is paramount, our Peripheral Heating Corrugating Roll excels by saving more than 10% of energy compared to conventional solutions. The efficient steam circulation system ensures continuous heat generation without condensation, making it an environmentally friendly and cost-effective choice for modern packaging operations.

Speed and Performance

The packaging corrugated roll from Zhejiang Yonghui is designed to meet the demands of high-speed production lines. Our advanced heating system allows the corrugating roll to operate at speeds ranging from 200 to 400 meters per minute, significantly enhancing productivity and efficiency. This speed increase is achieved without compromising the quality of the corrugated cardboard, ensuring that your final product meets high standards.

Quality and Adhesion

Maintaining a uniform temperature curve throughout the working width of the Peripheral Heating Corrugating Roll ensures consistent diameter and outstanding adhesion. This consistency is vital for preventing defects and ensuring that the corrugated cardboard maintains its structural integrity. Additionally, the roll's design prevents the banana effect, a common issue where the cardboard deforms when the roll stops, further enhancing the quality of your final product.

Easy Maintenance and Sustainability

Our Periphery Heating Flute Roller features an outstanding condensation reflux system, making it easy to maintain and eliminating the need for a siphon. This design not only simplifies maintenance procedures but also contributes to a more sustainable and eco-friendly production process. By reducing the need for additional maintenance equipment and minimizing energy consumption, our rolls help you achieve a more sustainable packaging operation.

Why Choose Zhejiang Yonghui?

When you choose Zhejiang Yonghui, you are partnering with a company that has over 20 years of industry experience and a proven track record of innovation and advanced. Our commitment to research and development ensures that our products are always at the forefront of technological advancements. We work closely with our customers to understand their unique needs and provide tailored solutions that meet and exceed their expectations.

Our Peripheral Heating Corrugating Roll is not just a product; it is a solution that addresses pressing challenges in the corrugated cardboard industry. By choosing our rolls, you are investing in a future where high-speed production, energy efficiency, and consistent quality are not just goals but achievable realities.

Invest in Quality, Invest in Zhejiang Yonghui

The Peripheral Heating Corrugating Roll from Zhejiang Yonghui Corrugated Roller Co., Ltd. is a game-changer in the packaging industry. Our advanced heating system, enhanced durability, energy efficiency, and outstanding performance make it an ideal choice for manufacturers looking to optimize their corrugated cardboard production process. By choosing Zhejiang Yonghui, you are not only investing in high-quality products but also in a reliable partner committed to your success.

Contact us today to learn more about our innovative Peripheral Heating Corrugating Rolls and how they can transform your packaging operations.

English

English  Español

Español  Português

Português  عربى

عربى