In the dynamic world of corrugated packaging, ensuring the safety of operators is paramount. This extends to the use of high-speed corrugated sheet cutting machines, which require adherence to strict safety protocols. These machines, critical in the production process, are designed to cut and shape corrugated sheets into various packaging materials. However, with their high-speed operations, they can pose significant risks if not handled properly. Here, we'll discuss essential safety measures that operators of corrugated sheet cutting machines and those around them should follow.

Understanding the Machinery

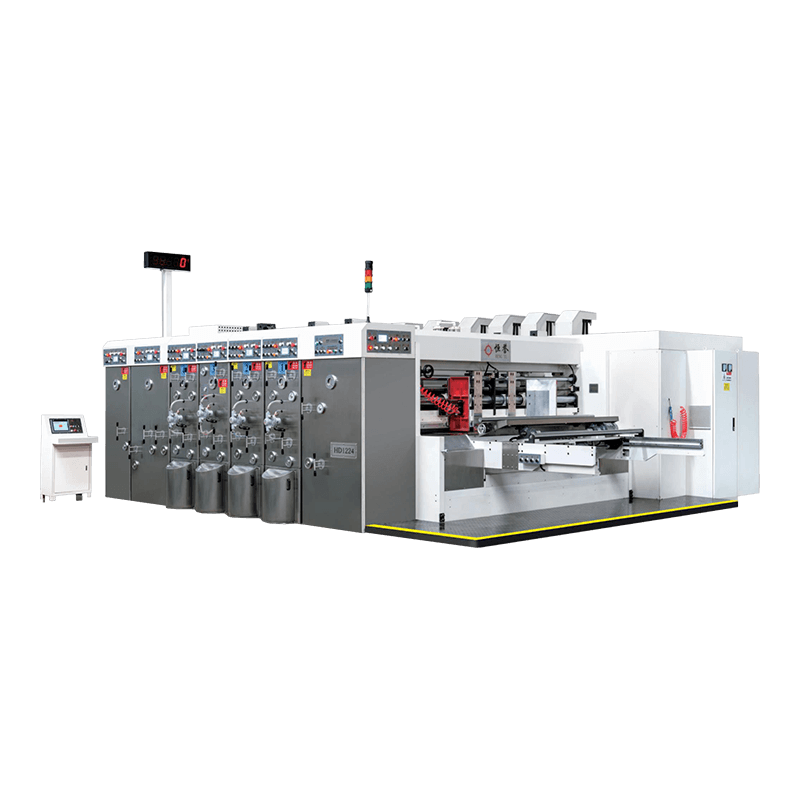

Before operating a corrugated sheet cutting machine, it's crucial to understand its components and functions. This includes recognizing the difference between a cutting machine, which is designed for precise cutting, and a corrugated sheet printing machine, which adds graphics to the sheets. Each machine has unique safety considerations due to their specific functions and the speed at which they operate.

Pre-Operational Checks

Before starting the corrugated sheet cutting machine, operators must perform a series of pre-operational checks. This includes inspecting the machine for any loose parts, checking the blade sharpness, and ensuring that all safety guards are in place and functioning correctly. It is also essential to confirm that the corrugated sheets to be cut are free from any defects that could cause the machine to jam or malfunction.

Protective Equipment

Wearing appropriate personal protective equipment (PPE) is non-negotiable when operating a corrugated sheet cutting machine. This includes safety glasses to protect the eyes from flying debris, hearing protection to shield against loud noises, and steel-toed boots to prevent foot injuries. Gloves should be avoided as they can get caught in moving parts of the machine.

Training and Certification

Only trained and certified operators should be allowed to handle a corrugated sheet cutting machine. Training should cover the machine's operation, safety features, and emergency procedures. Certification ensures that operators are competent and knowledgeable about the safe operation of the machinery.

Operation Safety

During operation, it's crucial to maintain a clear workspace around the corrugated sheet cutting machine. No loose items should be within reach of the machine to prevent accidental activation or obstruction of the cutting process. Operators should also avoid reaching into the machine while it is running to prevent injury.

Maintenance and Cleaning

Regular maintenance of the corrugated sheet cutting machine is essential for safety. This includes cleaning the machine after each use to remove any dust or debris that could cause slips, trips, or machinery malfunctions. Proper maintenance also ensures that the machine operates at peak efficiency, reducing the risk of accidents.

Emergency Procedures

Operators must be familiar with emergency procedures in case of a malfunction or injury. This includes knowing how to quickly stop the corrugated sheet cutting machine and where the emergency stop button is located. In the event of an incident, it's essential to follow established protocols, such as reporting the incident and ensuring that good aid is administered promptly.

Post-Operational Checks

After the machine has been turned off and all cutting operations have ceased, a post-operational check should be conducted. This involves inspecting the corrugated sheet cutting machine for any signs of wear or damage that could affect its performance during the next operation. It also includes ensuring that all corrugated sheets have been removed safely and that the work area is clear.

The safety of operators is integral to the efficient and effective production of corrugated packaging. By following these safety protocols for high-speed corrugated sheet cutting machines, operators can mitigate risks and ensure a safe working environment. It's important to remember that safety is everyone's responsibility, from the machine operators to the management overseeing the corrugated sheet printing machine and other related equipment. Through vigilance and adherence to safety protocols, the potential for accidents can be significantly reduced, allowing the industry to continue to thrive.

English

English  Español

Español  Português

Português  عربى

عربى