In the packaging industry, precision is everything. The meticulous engineering behind high-speed corrugated slitters is a testament to this fact. These machines, designed to cut and shape corrugated cardboard into precise patterns, play a critical role in the manufacturing of boxes and cartons. The accuracy of a corrugated slitter is not just a matter of functionality; it's a measure of its engineering prowess.

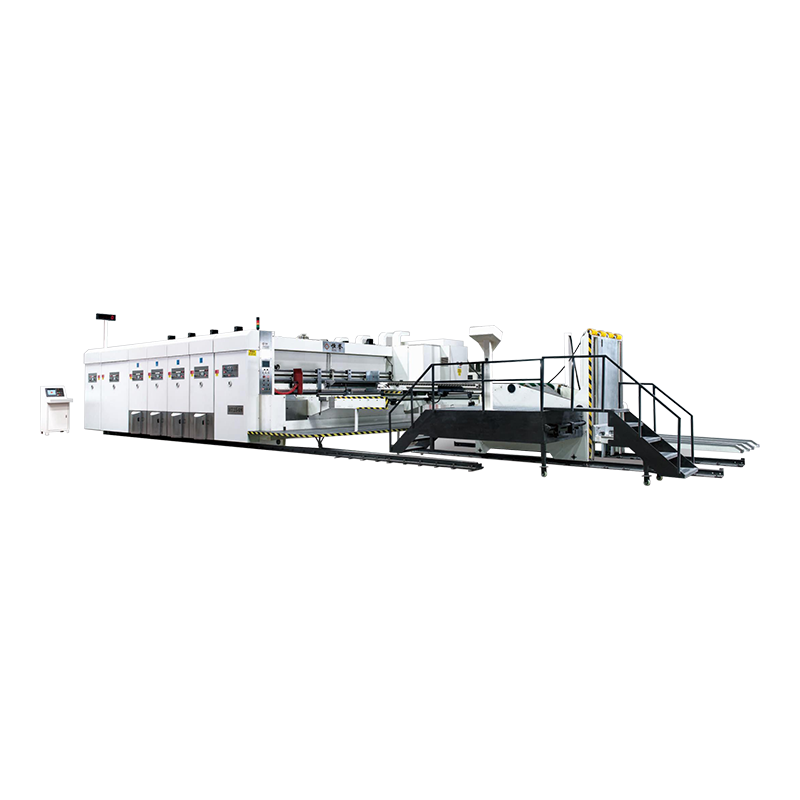

The corrugated slitter is a machine that has been engineered to handle high-speed operations while maintaining the very precision. This is crucial in an industry where even the slightest deviation can cause wasted material and increased production costs. The machine's design is a marvel of modern engineering, combining speed with accuracy to meet the demands of a fast-paced manufacturing environment.

The heart of the corrugated slitter is its cutting mechanism, which is designed to slice through layers of corrugated cardboard with surgical precision. This is where the term corrugated slotter machine comes into play. The slotter part of the name refers to the machine's ability to create slots and channels in the cardboard, which are essential for the folding process that gives corrugated boxes their structure. The high-speed nature of these machines means that they must be able to perform these operations rapidly, without compromising on the precision that is required for a great cut.

One of the key features of a high-speed corrugated slotting machine is its use of advanced materials and effective technology. The blades used in these machines are made from high-quality steel that is designed to withstand the rigors of continuous use. This is important because the corrugated slotter machine is expected to operate at high speeds for extended periods, which can put a lot of wear and tear on its components. By using durable materials, the machine's longevity is increased, and the need for frequent replacements is minimized.

The engineering behind a high-speed corrugated slotting machine also involves sophisticated control systems that ensure the machine's movements are precise and consistent. These systems are responsible for guiding the blades as they cut through the cardboard, ensuring that each cut is made in the exact same way. This is crucial for maintaining the uniformity of the final product, as any variation in the cuts can cause boxes that don't fold properly or that have uneven edges.

Another aspect of the engineering marvel that is the corrugated slitter is its ability to handle different types of corrugated cardboard. The machine must be able to adjust its settings to accommodate different thicknesses and grades of cardboard. This flexibility is essential in an industry where the specific requirements of a job can vary widely. By being able to adapt to different materials, the corrugated slitter ensures that it can produce high-quality results regardless of the specific task at hand.

The term corrugated slotting machine is also used to describe the machine's ability to create precise slots in the cardboard. These slots are crucial for the assembly of the boxes, as they allow for the cardboard to be folded into its final shape. The precision of these slots is a direct result of the engineering that goes into the design of the machine. By ensuring that each slot is cut to the exact same specifications, the corrugated slotting machine guarantees that the boxes it produces will have a consistent and professional appearance.

The engineering behind high-speed corrugated slitters is not just about the machines themselves, but also about the processes that they enable. The ability of these machines to cut and shape cardboard with such precision allows for the production of boxes and cartons that are both functional and aesthetically pleasing. This is important in an industry where the appearance of a product can have a significant impact on its marketability.

The engineering behind high-speed corrugated slitters is a complex and fascinating field that combines speed, precision, and adaptability. The machines are engineered to perform at high speeds while maintaining the accuracy required for flawless corrugated cardboard processing. The corrugated slotter machine and corrugated slotting machine are terms that encapsulate the precision and versatility of these engineering marvels. As the packaging industry continues to evolve, the need for high-speed, accurate, and reliable corrugated slitters will only grow, driving further innovation and development in this critical area of manufacturing.

English

English  Español

Español  Português

Português  عربى

عربى