The printing industry has witnessed a significant transformation with the advent of digital technology. Among the various printing methods, digital flexographic printing stands out as a game-changer, offering new opportunities and challenges compared to traditional flexo printing.

Understanding Flexo Printing Equipment

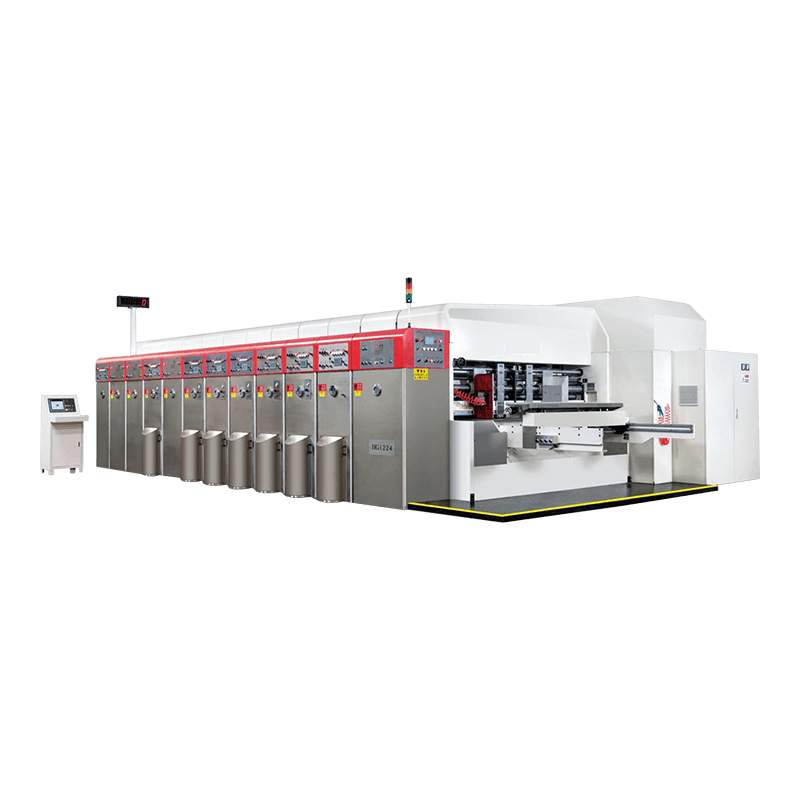

Flexo printing equipment has long been the backbone of the packaging and label industry. Traditionally, these machines relied on a flexographic printing process that involved the use of flexible rubber plates mounted on a cylinder. The plates were inked, and the image was transferred onto the substrate, such as paper or plastic, as it passed through the press. This method was widely used due to its versatility, cost-effectiveness, and ability to print on a variety of materials. However, the advent of digital flexographic printing has introduced new possibilities that are reshaping the industry.

The Rise of Digital Flexo Printing

Digital flexo printing is an innovative approach that combines the benefits of digital technology with the traditional flexo process. It offers a more efficient and cost-effective solution for short to medium print runs. The core of digital flexo printing lies in the automatic flexo printing machine, which uses digital technology to create high-quality prints that were once only achievable through traditional methods. This advancement has brought about several key differences between digital and traditional flexo printing.

Precision and Quality

One of significant advantages of digital flexo printing is its precision. Automatic flexo printing machines can achieve a higher level of detail and accuracy compared to traditional methods. This is due to the use of advanced imaging systems that allow for precise plate creation. Digital flexographic printing also offers better color consistency across the entire print run, which is crucial for maintaining brand identity and product recognition.

Sustainability and Waste Reduction

Sustainability is a growing concern in the printing industry, and digital flexo printing addresses this issue more effectively than traditional methods. The process requires fewer setup times and less waste, as plates can be digitally prepared and adjusted without the need for physical proofing or plate remakes. This not only reduces waste but also conserves resources, making digital flexo printing a more environmentally friendly option.

Cost-Effectiveness

While the initial investment in digital flexographic printing equipment can be higher than traditional flexo printing machines, the long-term cost savings are significant. Digital flexo printing reduces the need for large quantities of plates, ink, and other materials, as well as labor costs associated with setup and plate preparation. This makes digital flexo printing more cost-effective for short to medium runs, which are increasingly common in today's fast-paced market.

Flexibility and Customization

Flexo printing equipment, whether traditional or digital, is known for its flexibility in handling various substrates and applications. However, digital flexo printing takes this flexibility to a new level. Automatic flexo printing machines can quickly switch between different print jobs, making them ideal for personalized and variable data printing. This level of customization is particularly valuable in industries such as packaging, where unique and targeted messaging can drive consumer engagement.

Adaptability to Market Trends

The market is increasingly demanding quick turnaround times and the ability to adapt to changing trends. Digital flexo printing is well-suited to meet these demands. With the ability to produce short runs economically and the flexibility to change designs on the fly, automatic flexo printing machines can respond to market changes more quickly than traditional methods. This adaptability is crucial for businesses looking to stay competitive in a rapidly evolving market.

The future of printing lies at the intersection of tradition and innovation. Digital flexo printing represents a significant leap forward in the industry, offering benefits such as precision, sustainability, cost-effectiveness, flexibility, and adaptability. As technology continues to advance, the adoption of digital flexographic printing and the utilization of automatic flexo printing machines will likely increase, further transforming the way we approach flexo printing equipment and processes.

English

English  Español

Español  Português

Português  عربى

عربى