Introduction

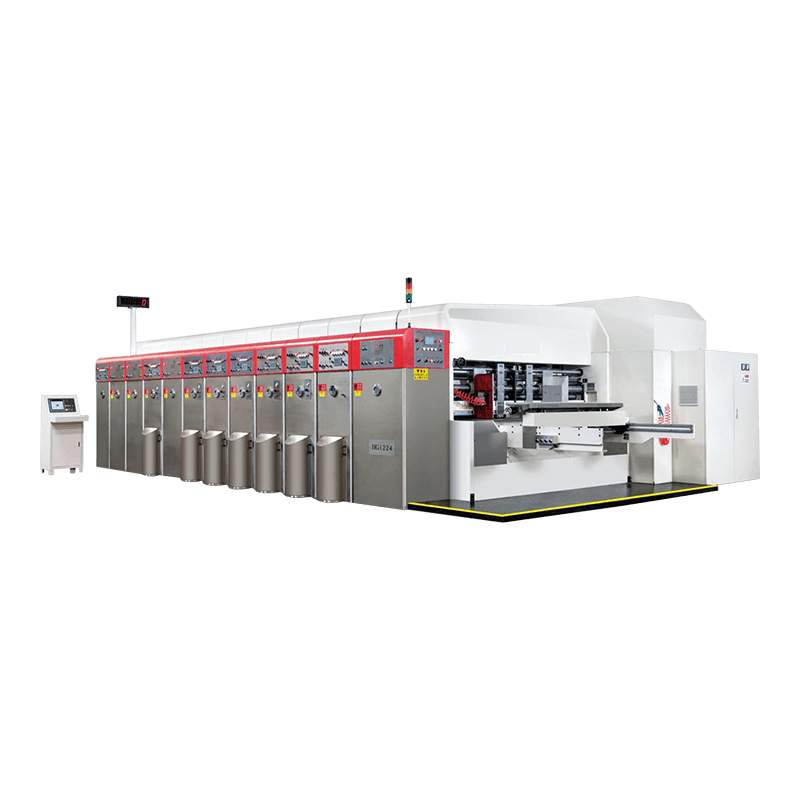

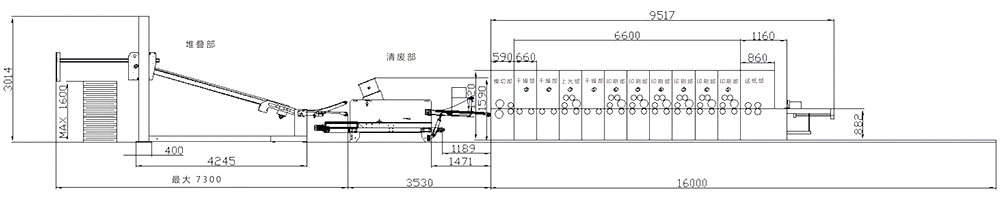

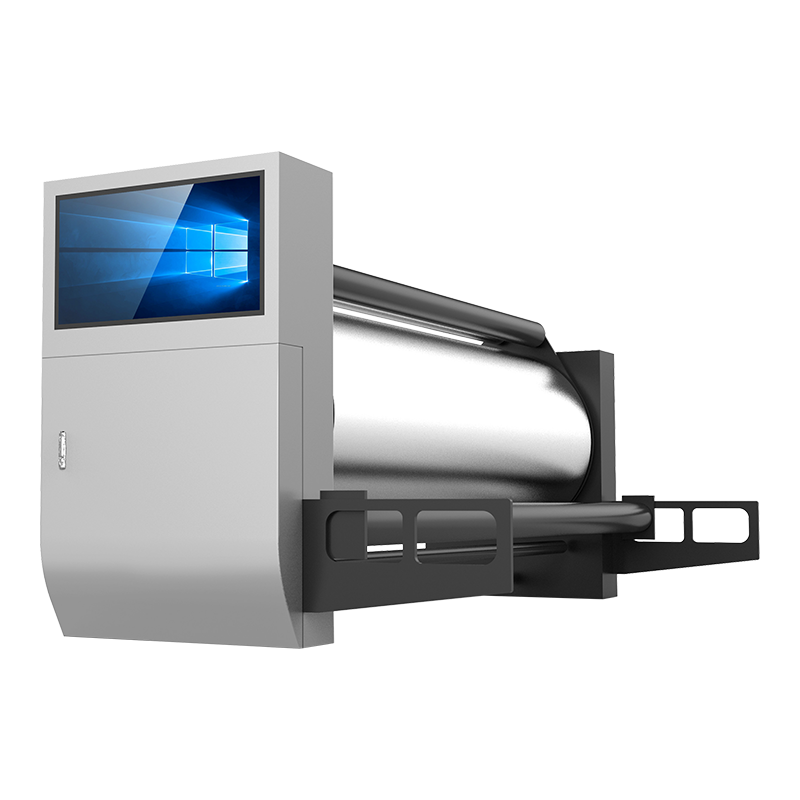

The High Definition Computerized Flexo Printing Die Cutting Machine is designed with advanced concepts from Europe and the United States. It features a mobile unit, full vacuum adsorption printing, and is equipped with hot air, infrared, UV, and independent drying systems. The die-cutting section is driven by a servo motor for independent control, ensuring precise performance. Remote maintenance and quick troubleshooting are available for efficient operation.

Main Unit

1. Feeder Unit:

The machine uses a Sun Automation Lead Edge Feeder with strong vacuum transfer for accurate and stable feeding.

A dust removal system with a brush and segmented vacuum sheet ensures clean feeding.

A self-locking system adjusts the feeding roll gap automatically, with motorized cleaning.

The feeder side guides are controlled by PLC for precise adjustments.

The main motor is protected to prevent startup if the units are not fully closed or locked.

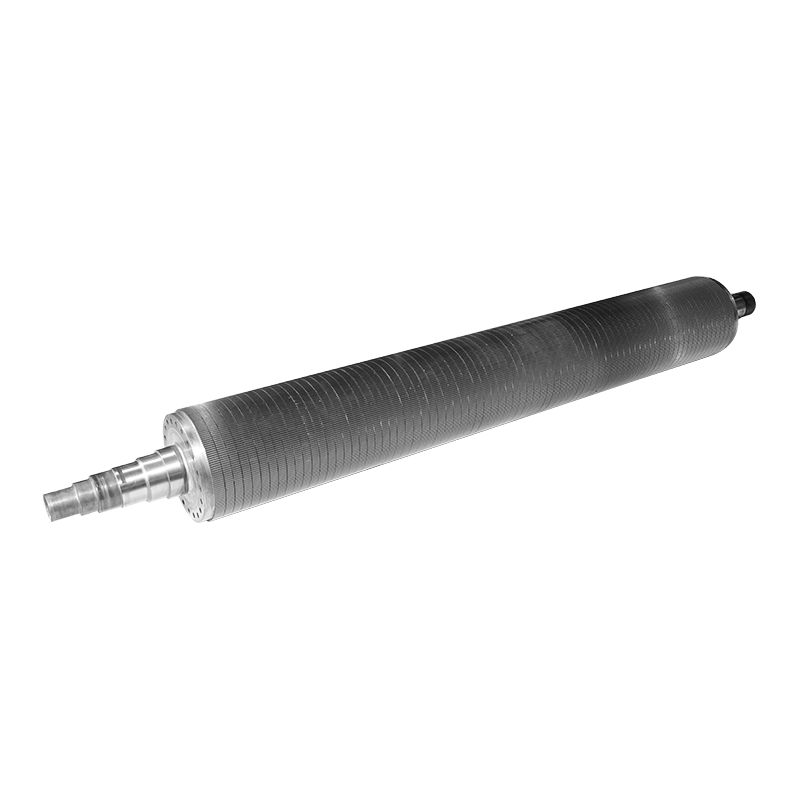

2. Printer Unit with Vacuum Transfer/Coating Unit:

The printer features a pneumatic clutch on the anilox roll, which:

(a) synchronizes with the main motor during printing,

(b) stops when the unit is idle,

(c) minimizes damage to the rubber and anilox rolls,

(d) allows washing of unused units while the machine runs.

The transverse register is controlled digitally by motor and PLC with an adjustable range of ±10mm.

The cleaning function is automated for thorough ink recycling, with automatic reset after the cleaning process.

An optional Doctor-Blade Inking System is available for improved ink management.

3. Drying Unit:

The machine can be equipped with independent drying devices including hot air, infrared, or UV systems to optimize drying efficiency.

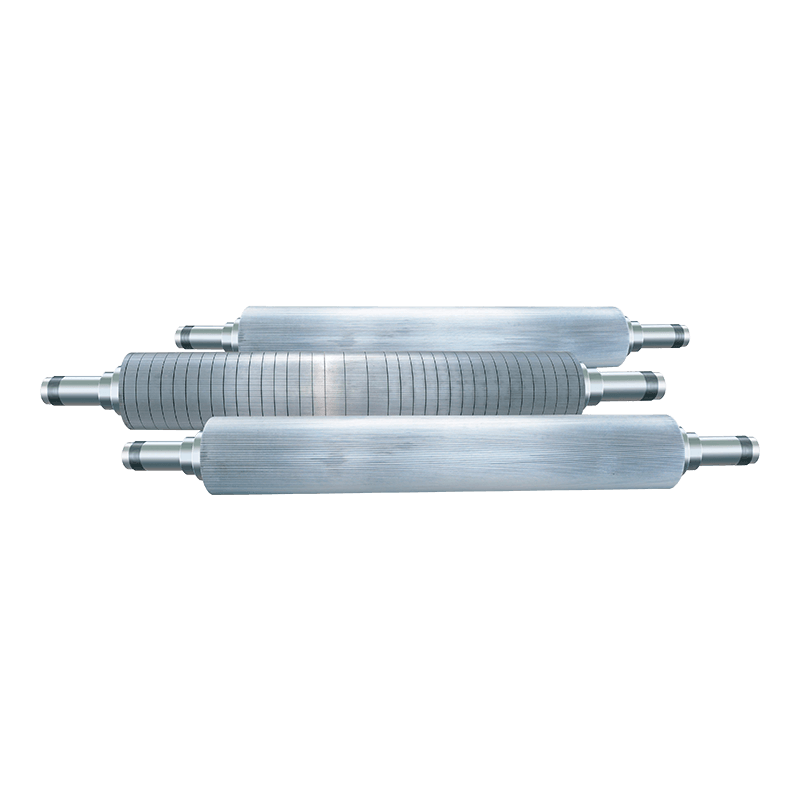

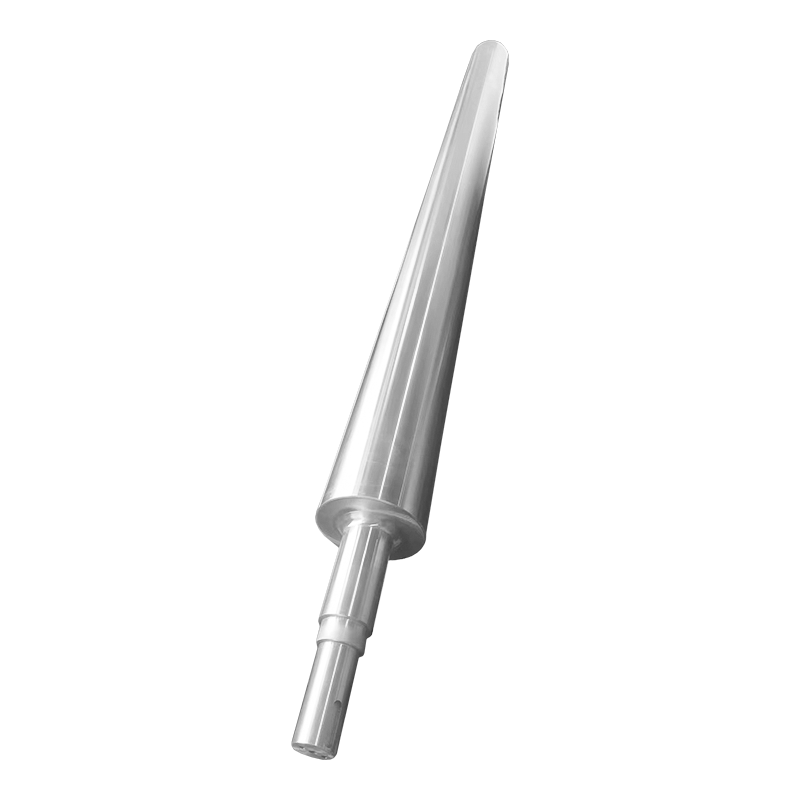

4. Die-Cutting Unit:

The anvil drum moves side-to-side (50mm oscillation) for precise die-cutting.

The lateral register of the die-cut cylinder is digitally controlled by motor and PLC, with a range of ±10mm.

The anvil rubber roller speed is compensated via an independent motor, with a compensation range of ±3mm.

An anvil trimmer ensures a flat and smooth surface for the anvil covers.

The die-cutting unit features servo independent drive for enhanced control and accuracy.

English

English  Español

Español  Português

Português  عربى

عربى