In the paper and packaging industry, efficiency and quality often depend on precise machinery. One component that has gained attention is the Peripheral Heating Corrugating Roller. This roller plays a crucial role in producing corrugated board by evenly heating and shaping paper sheets. Understanding its design and functionality can help manufacturers achieve consistent results.

Role in the Corrugating Process

The Peripheral Heating Corrugating Roller is designed to maintain uniform temperature across its surface. This consistent heat ensures that the adhesive applied to the paper bonds properly and that the corrugated shape holds during production. Uneven heating can cause defects such as weak flutes or uneven adhesion, which compromise product quality.

By maintaining controlled heating, these rollers also help in reducing production errors. The consistent temperature reduces the chances of paper tearing or improper glue curing, which can slow down the production line.

Design and Construction

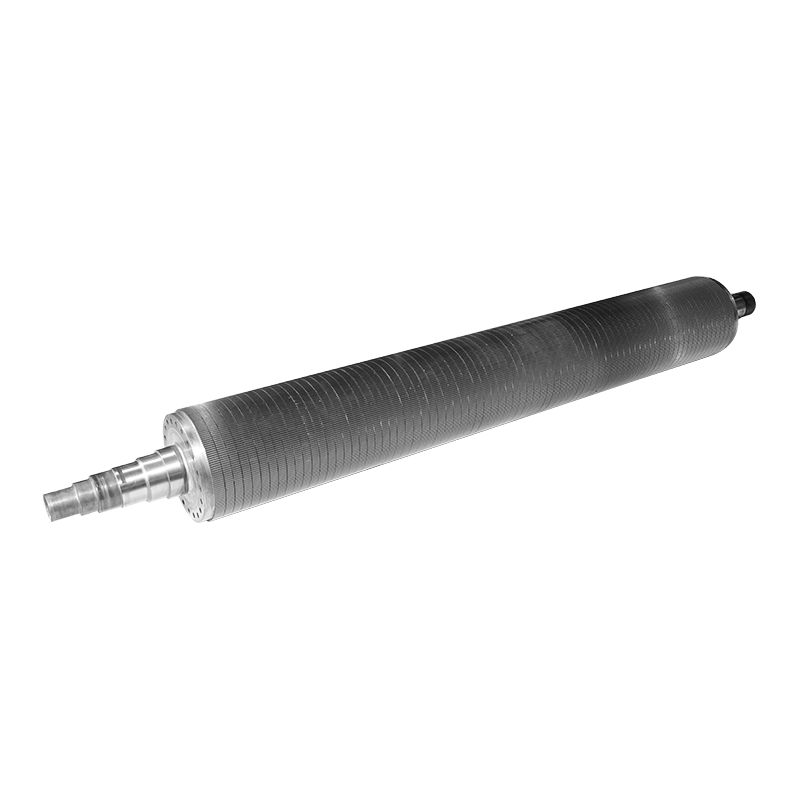

A typical Peripheral Heating Corrugating Roller consists of a metal core, a heating mechanism, and a surface layer that contacts the paper. The heating method can vary, often using electrical heating elements or steam circulation. The surface layer may be coated with materials that improve heat transfer while providing a smooth contact point for the paper.

Manufacturers focus on durability and stability when designing these rollers. Since they operate under continuous stress and high temperatures, maintaining structural integrity is essential. This ensures that the roller performs reliably over long production runs.

Benefits in Production

One of the key advantages of using a Peripheral Heating Corrugating Roller is the improvement in product consistency. Corrugated boards produced with evenly heated rollers tend to have better structural strength and appearance. The controlled heat also allows for higher production speeds without compromising quality.

Additionally, these rollers can be adapted to work with various types of paper, including recycled materials. This flexibility is valuable for manufacturers aiming to handle different product lines without frequent equipment changes.

Maintenance and Longevity

Proper maintenance is crucial for the long-term performance of a Peripheral Heating Corrugating Roller. Regular inspection of heating elements, surface coatings, and bearings ensures that the roller remains effective. Cleaning and preventive maintenance prevent residue build-up, which can affect heat transfer and cause uneven corrugation.

Many factories implement a scheduled maintenance plan, which not only extends the roller's life but also reduces unexpected downtime. Attention to detail during maintenance ensures that production remains smooth and that product quality is consistently high.

Customization and Adaptability

Modern Peripheral Heating Corrugating Rollers often allow customization based on the manufacturer's needs. Adjustments in roller diameter, surface texture, and heating temperature make it possible to optimize performance for specific paper grades or production requirements.

This adaptability is particularly useful for factories producing specialized corrugated boards. By selecting the appropriate roller configuration, manufacturers can maintain efficiency while producing boards that meet precise specifications.

The Peripheral Heating Corrugating Roller is a vital component in corrugated board production. Its ability to provide consistent heat, support various materials, and maintain structural integrity directly affects product quality and operational efficiency. Understanding its function, maintenance requirements, and customization options can help manufacturers improve production outcomes while ensuring durability and reliability.

English

English  Español

Español  Português

Português  عربى

عربى