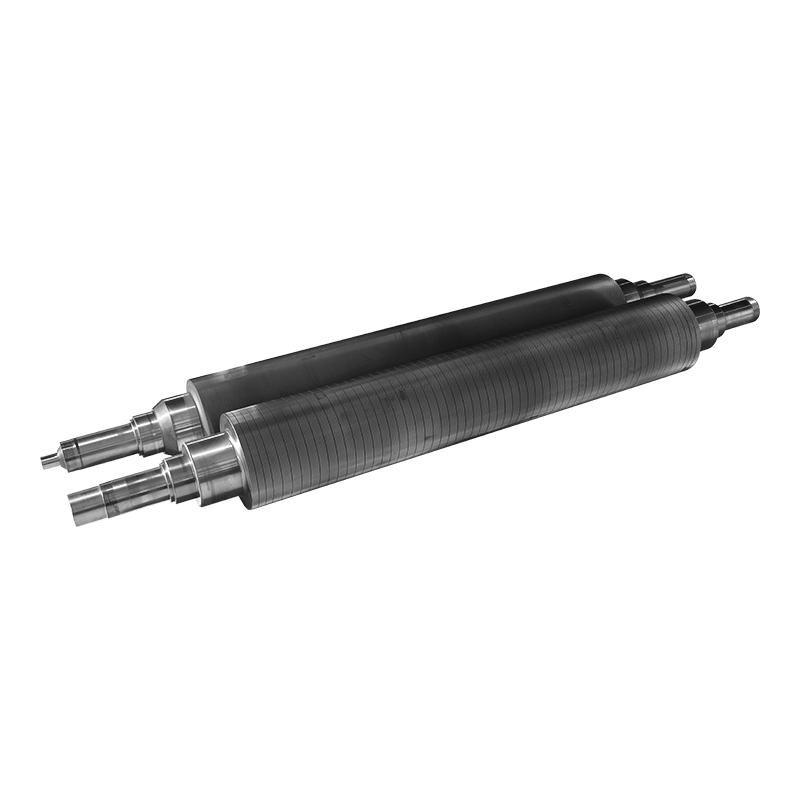

In the corrugated board manufacturing industry, the quality and durability of equipment components are crucial. One key element is the Tungsten Carbide Corrugating Roller, which directly affects both the efficiency of production and the consistency of the finished product. These rollers are widely valued for their wear resistance, precision, and ability to withstand continuous operation in demanding environments.

Material Properties and Durability

The main advantage of a Tungsten Carbide Corrugating Roller comes from its material. Tungsten carbide is known for its hardness, abrasion resistance, and stability under high temperatures. Compared to traditional steel rollers, it can resist deformation and surface wear over long periods of use. In a factory where rollers encounter heat, adhesives, and high-speed friction, this material ensures consistent performance with minimal downtime.

Additionally, tungsten carbide's resistance to corrosion and scratches helps maintain the roller's surface quality. This is especially important in high-volume production lines where even slight wear can affect corrugation accuracy and cause material waste. A Tungsten Carbide Corrugating Roller therefore contributes to both operational efficiency and product reliability.

Precision and Product Quality

Corrugated board requires precise flute formation to maintain strength and uniformity. A Tungsten Carbide Corrugating Roller provides a stable and accurate surface for shaping the paperboard. Its resistance to wear ensures that the corrugation pattern remains consistent over thousands of production cycles.

This precision reduces the need for frequent adjustments or recalibration, saving labor and minimizing interruptions in the production line. Factories using these rollers often notice fewer defects, which helps in producing uniform corrugated boards suitable for packaging, shipping, or other industrial applications.

Maintenance and Longevity

Even though a Tungsten Carbide Corrugating Roller is highly durable, proper maintenance is still important. Regular cleaning to remove adhesive or paper residues, surface inspections for minor wear, and lubrication all help extend the roller's service life. Compared to conventional rollers, tungsten carbide options require fewer replacements, which can reduce maintenance costs and production downtime.

Some factories also apply protective coatings to extend the roller's lifespan even further. This combination of material strength and careful maintenance ensures that the roller can perform reliably under continuous or heavy-duty usage.

Industrial Applications

Beyond standard corrugated board production, a Tungsten Carbide Corrugating Roller can be used in specialty applications. For instance, factories producing heavy-duty packaging, custom flute profiles, or multilayer corrugated products benefit from the roller's ability to maintain precise patterns. Its versatility allows manufacturers to adapt to various production requirements without compromising quality.

Moreover, these rollers are compatible with both single and double facer corrugators, making them suitable for a range of machines. The adaptability of a Tungsten Carbide Corrugating Roller enhances its practical value in modern corrugated board manufacturing.

A Tungsten Carbide Corrugating Roller is a key component in ensuring efficiency, precision, and durability in corrugated board production. By combining the hardness and wear resistance of tungsten carbide with proper maintenance, factories can maintain consistent corrugation patterns while reducing downtime and operational costs. Its versatility in standard and specialized applications makes it a reliable choice for manufacturers seeking stability and longevity in their production lines. Understanding the role of these rollers highlights their importance in maintaining quality and operational continuity across the corrugated board industry.

English

English  Español

Español  Português

Português  عربى

عربى