In the corrugated board industry, maintaining consistent quality and production speed is crucial. A Peripheral Heating Corrugating Roller plays a key role in this process by providing controlled heat during the corrugation stage. This ensures that adhesive bonds set properly and that the fluted paper maintains its shape, which improves both efficiency and product reliability.

Section 1: Key Features of a Peripheral Heating Corrugating Roller

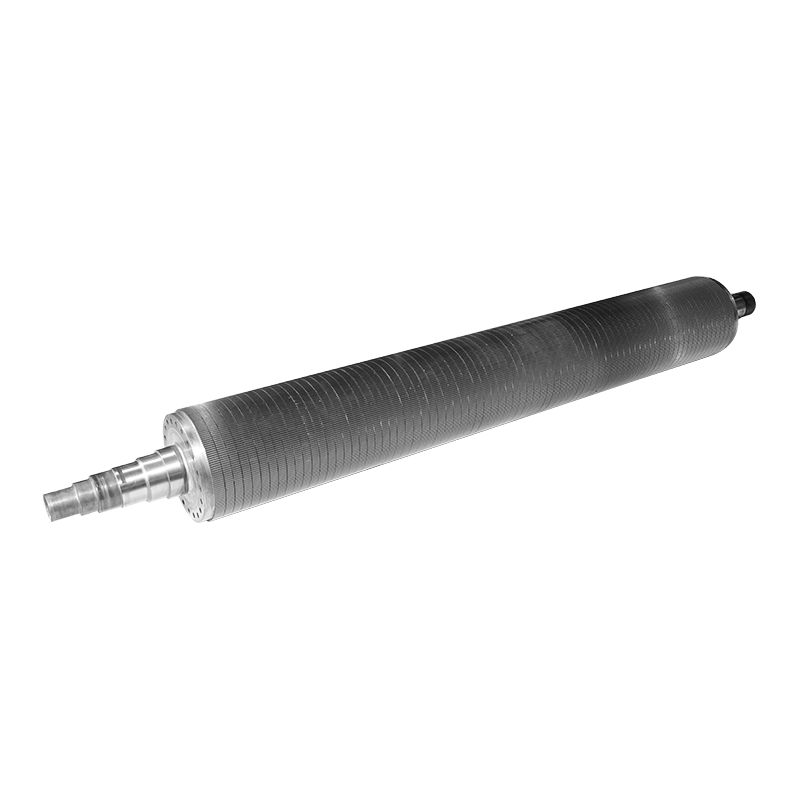

A Peripheral Heating Corrugating Roller is designed to apply heat evenly across the roller surface while the corrugating paper passes through. Unlike standard rollers, its peripheral heating system ensures consistent temperature control, reducing the risk of uneven bonding or material deformation.

Even Heat Distribution

The main advantage of a Peripheral Heating Corrugating Roller is its ability to distribute heat uniformly along the roller's surface. This ensures that the adhesive used in corrugated board production sets evenly, preventing weak spots and improving the structural strength of the final product.

Durable Construction

These rollers are typically made of high-quality steel or alloy materials, capable of withstanding high temperatures and repeated use. The combination of durability and precision makes a Peripheral Heating Corrugating Roller suitable for high-speed production lines.

Temperature Control

Many models allow precise temperature adjustment to match different paper types or adhesive formulations. By maintaining heat, the Peripheral Heating Corrugating Roller helps achieve consistent bonding and reduces the chances of paper deformation or wrinkling.

Section 2: Applications in Corrugated Board Manufacturing

Single-Face Corrugators

In single-face corrugated board production, a Peripheral Heating Corrugating Roller ensures that the fluted medium adheres smoothly to the liner board. Even heat application prevents bubbles or uneven adhesion, which could compromise the board's strength.

Double-Face Corrugators

For double-face boards, precise heat control is even more critical. The Peripheral Heating Corrugating Roller helps bond both layers consistently, ensuring that the finished board maintains its rigidity and flatness during stacking and shipping.

Flexible Paper Types

Different paper grades react differently to heat. A properly controlled Peripheral Heating Corrugating Roller allows manufacturers to adjust the temperature according to the paper type, ensuring consistent production quality across various materials.

Section 3: Practical Considerations

Maintenance and Cleaning

Regular maintenance of a Peripheral Heating Corrugating Roller ensures consistent performance. Cleaning the roller surface, inspecting heating elements, and checking temperature sensors helps prevent uneven heating or production downtime.

Integration with Existing Equipment

When selecting a Peripheral Heating Corrugating Roller, it is important to ensure compatibility with current corrugators. Proper alignment, size, and mounting options contribute to smooth operation and reduced material waste.

Energy Efficiency

Some modern rollers are designed to minimize energy consumption while maintaining heat stability. Choosing a Peripheral Heating Corrugating Roller with energy-efficient features can reduce operating costs over time.

Reliable Performance for Corrugated Board Production

A Peripheral Heating Corrugating Roller is a vital component in the production of corrugated boards. Its uniform heat distribution, precise temperature control, and durable construction ensure that boards are strong, flat, and consistent in quality. By maintaining proper roller operation and selecting the right model for specific production lines, manufacturers can improve efficiency, reduce material waste, and maintain consistent product performance. For anyone involved in corrugated board manufacturing, a Peripheral Heating Corrugating Roller offers a practical and reliable solution for high-quality output.

English

English  Español

Español  Português

Português  عربى

عربى