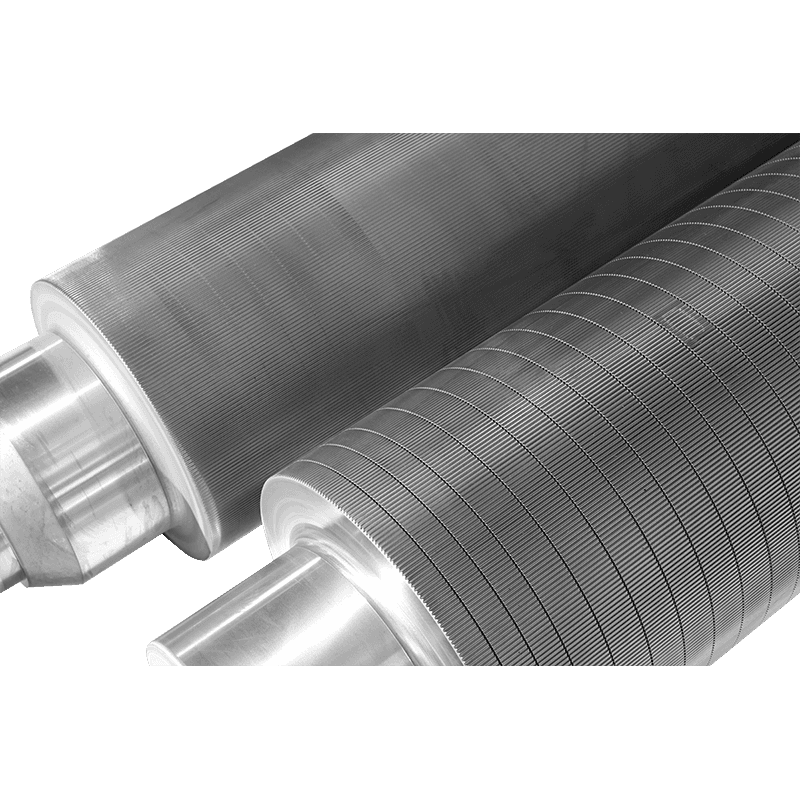

More Information About Tungsten Carbide Corrugating Rolls What You Need to Know

Q1: What Are Tungsten Carbide Corrugating Rolls, and Why Are They outstanding?

A: Tungsten carbide corrugating rolls are premium-grade rollers coated with an ultra-hard tungsten carbide layer, designed for durability in corrugated board production. Unlike traditional chrome-plated rolls, these rolls offer:

3–5x Longer Lifespan – Resists wear from abrasive recycled papers.

Higher Corrosion Resistance – Ideal for humid environments.

Precision Groove Retention – Maintains flute shape even after millions of meters of production.

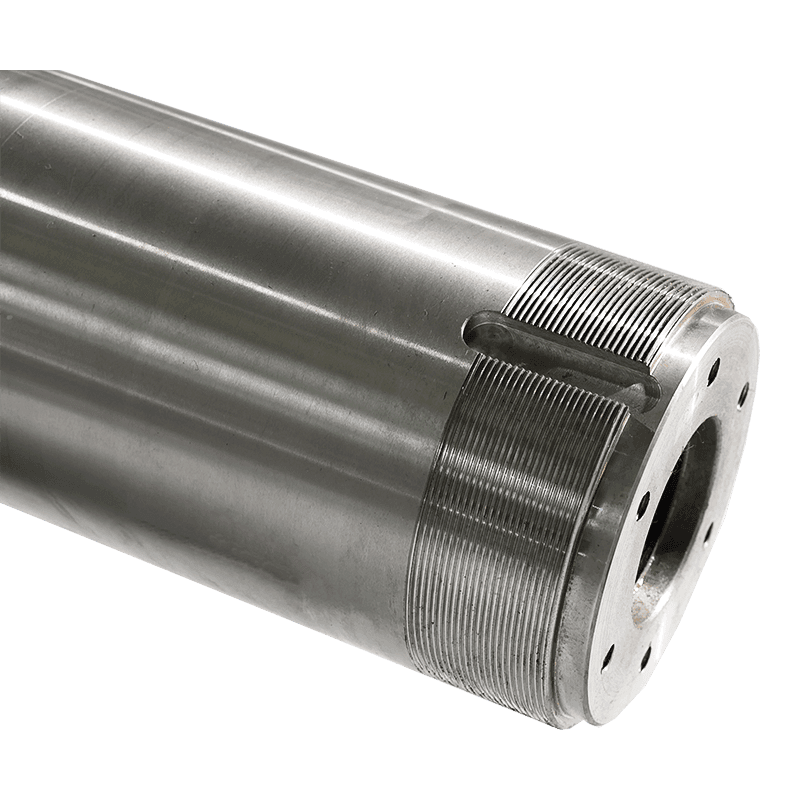

At Zhejiang Yonghui, our tungsten carbide finish corrugating rolls undergo advanced HVOF (High-Velocity Oxygen Fuel) coating for unmatched hardness (up to 70 HRC).

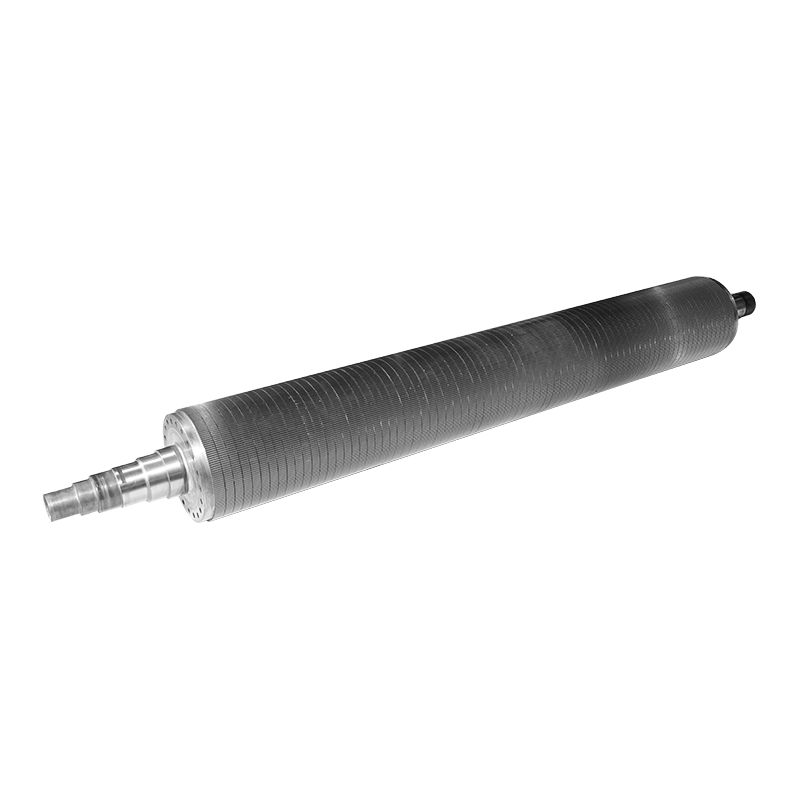

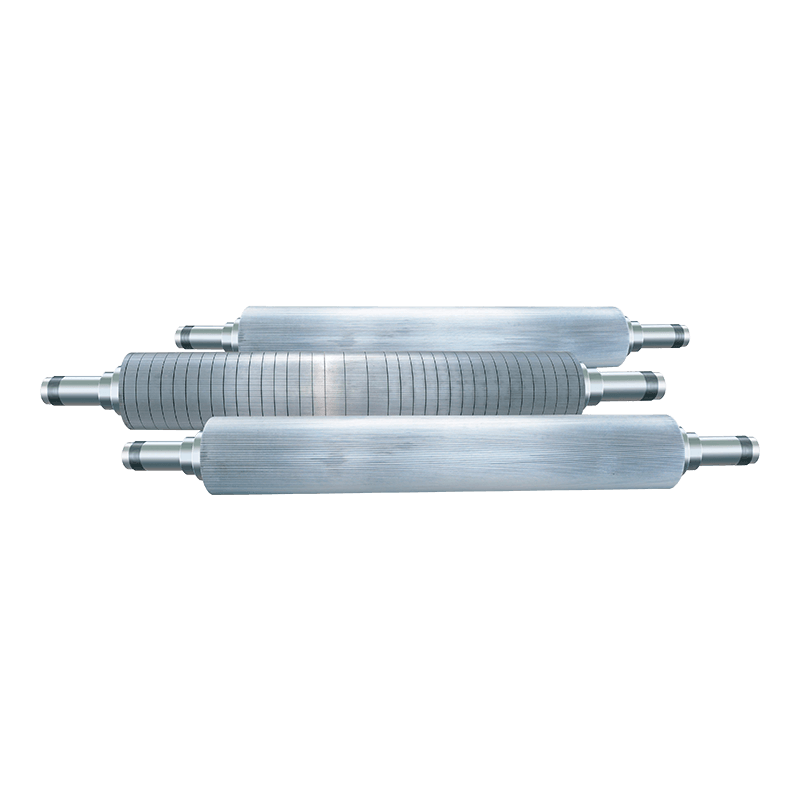

Q2: What Types of Tungsten Carbide Coated Corrugating Rolls Are Available?

A: We offer three key variants to match different production needs:

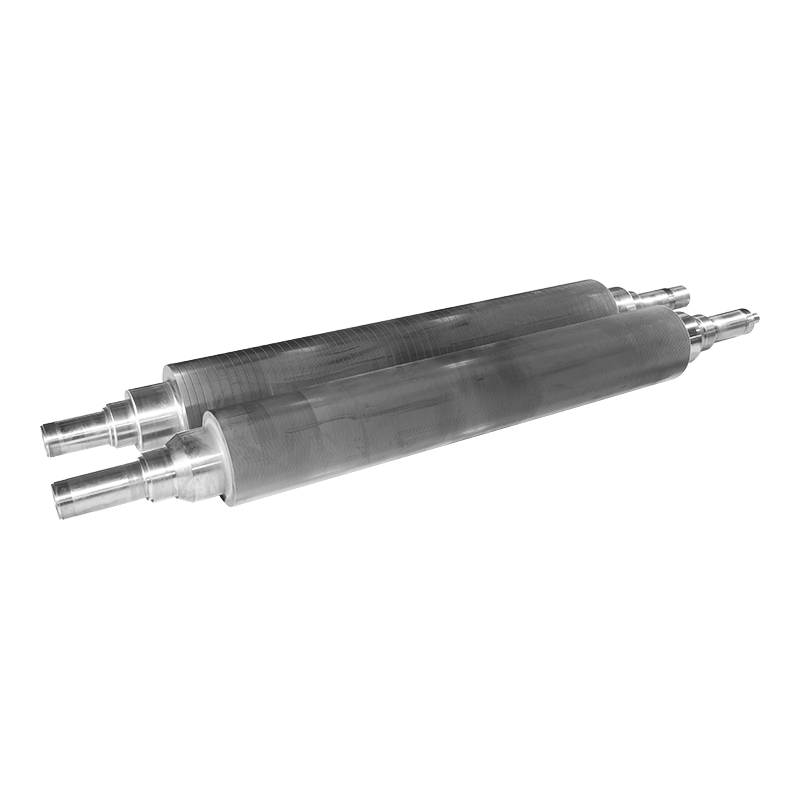

1. Standard Tungsten Carbide Corrugating Rolls

- for medium-duty production with mixed paper grades.

- Cost-effective upgrade from chrome-plated rolls.

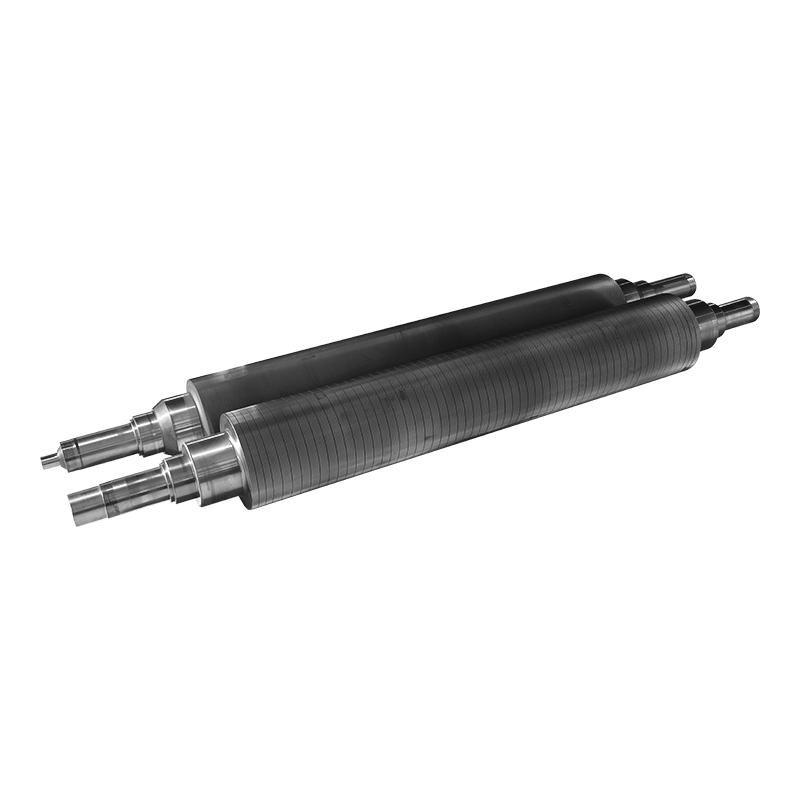

2. High-Performance Tungsten Carbide Finish Corrugating Rolls

- Enhanced coating thickness for heavy-duty use (50%+ recycled fiber).

- Reduces glue buildup and downtime.

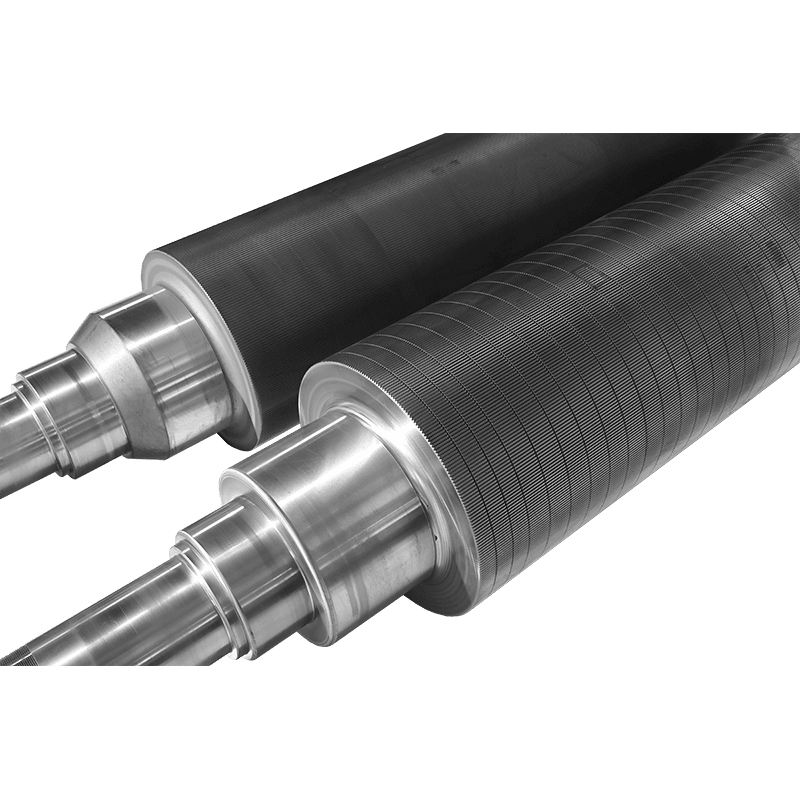

3. Custom-Engineered Tungsten Carbide Coated Corrugating Rolls

- Tailored flute profiles (A, B, C, E, F, N) for specialty boards.

- Optional anti-static treatment for dust-prone environments.

Buyer's Tip: If you run 24/7 production, opt for high-performance models to improve uptime.

Q3: How Do Tungsten Carbide Corrugating Rolls Improve Efficiency?

A: These rolls deliver measurable benefits:

- Energy Savings – Smoother surface reduces friction, cutting power use by 10–15%.

- Fewer Changeovers – Lasts 8–15 million linear meters before refurbishment (vs. 3–5M for chrome).

- Consistent Board Quality – Prevents flute deformation, ensuring uniform crush resistance.

Real-World Example: A professional packaging mill reported 30% less downtime after switching to our tungsten carbide coated corrugating rolls.

Q4: What Applications Are Suited for Tungsten Carbide Finish Corrugating Rolls?

A: Ideal for demanding scenarios, including:

- Recycled Corrugated Material – Resists abrasive fibers that degrade standard rolls.

- High-Speed Corrugators (300+ m/min) – Maintains precision at peak speeds.

- Moisture-Resistant Boards – Prevents pitting and rust in starch-heavy adhesives.

Niche Use Case:

A seafood exporter using our tungsten carbide corrugating rolls eliminated flute collapse in wet-condition packaging.

Q5: How Do I Maintain Tungsten Carbide Coated Corrugating Rolls?

A: Follow these practices:

1. Clean Weekly – Remove glue and debris with non-abrasive brushes.

2. Monitor Wear – Use groove micrometers; refurbish at 0.15mm wear depth.

3. Balance Annually – Prevent vibrations that misalign flutes.

Pro Tip: Pair with ceramic doctor blades to avoid scratching the coating.

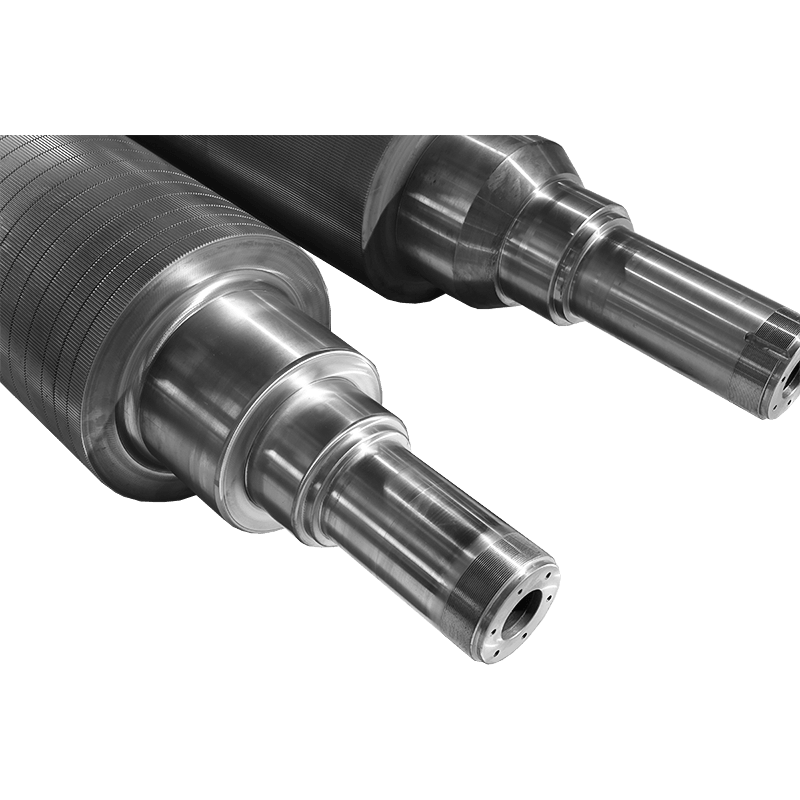

Q6: Why Choose Zhejiang Yonghui Roller's Tungsten Carbide Corrugating Rolls?

A: Our rolls stand out with:

- Certified HVOF Coating – Independently tested for adhesion and hardness.

- Dynamic Balancing – Ensures smooth operation at 500+ RPM.

- 5-Year Performance Guarantee – Backed by real-world case studies.

Cost Analysis:

While tungsten carbide finish corrugating rolls cost 20–30% more upfront, they save $50,000+ annually in reduced downtime and roll replacements.

For mills prioritizing longevity, efficiency, and ROI, tungsten carbide coated corrugating rolls are the definitive choice.

Zhejiang Yonghui for a free wear-rate assessment of your current rolls.

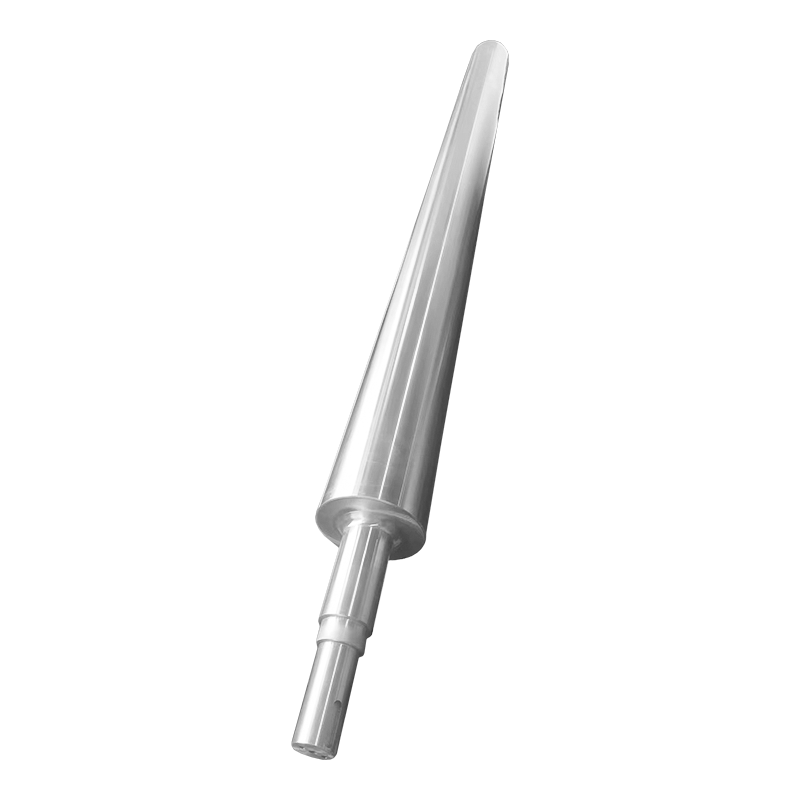

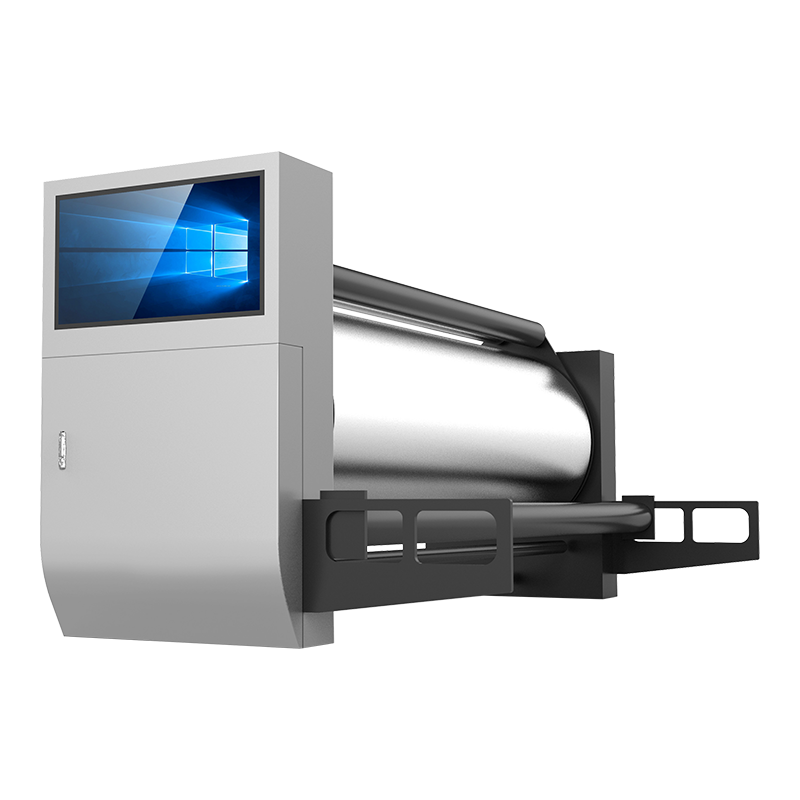

Tungsten Carbide Corrugating Rolls are premium-grade components designed for high-performance corrugated cardboard production. Engineered with a robust tungsten carbide coating, these rolls offer exceptional hardness, wear resistance, and thermal stability, making them ideal for high-speed and long-duration operations. The precise corrugation profiles ensure uniform flute formation, resulting in stronger board quality and improved bonding. Compared to traditional chrome-plated rolls, tungsten carbide corrugating rolls deliver significantly longer service life, reduced maintenance needs, and consistent output quality. They are the preferred choice for manufacturers seeking enhanced productivity, durability, and cost-efficiency in their corrugated production lines.

English

English  Español

Español  Português

Português  عربى

عربى