Contact us

Focused on the R&D and manufacturing of high-quality corrugated rollers, the "heart" component of the corrugated cardboard production line.

+86-18661680180

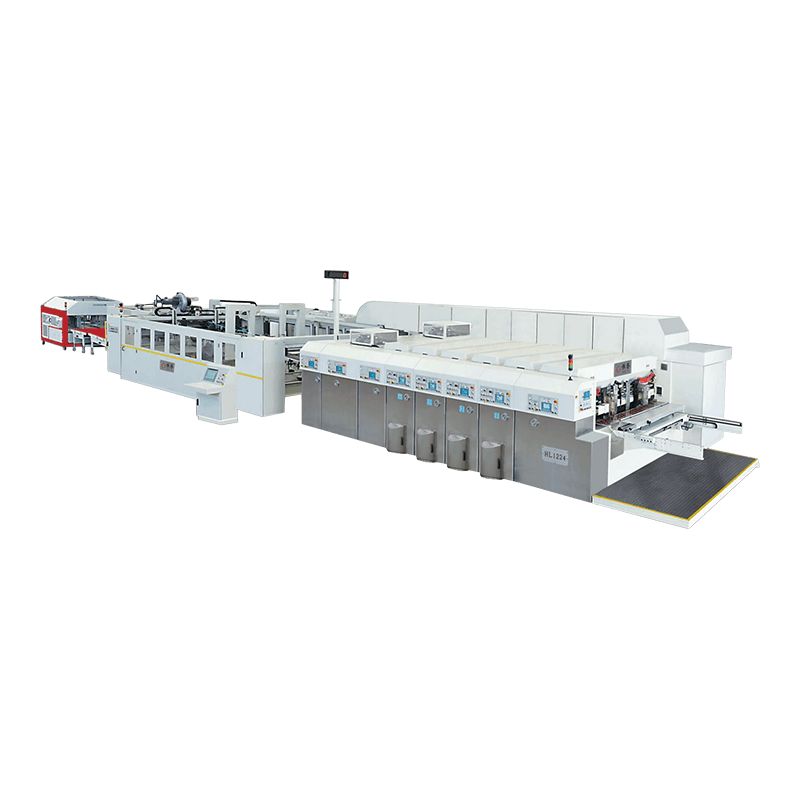

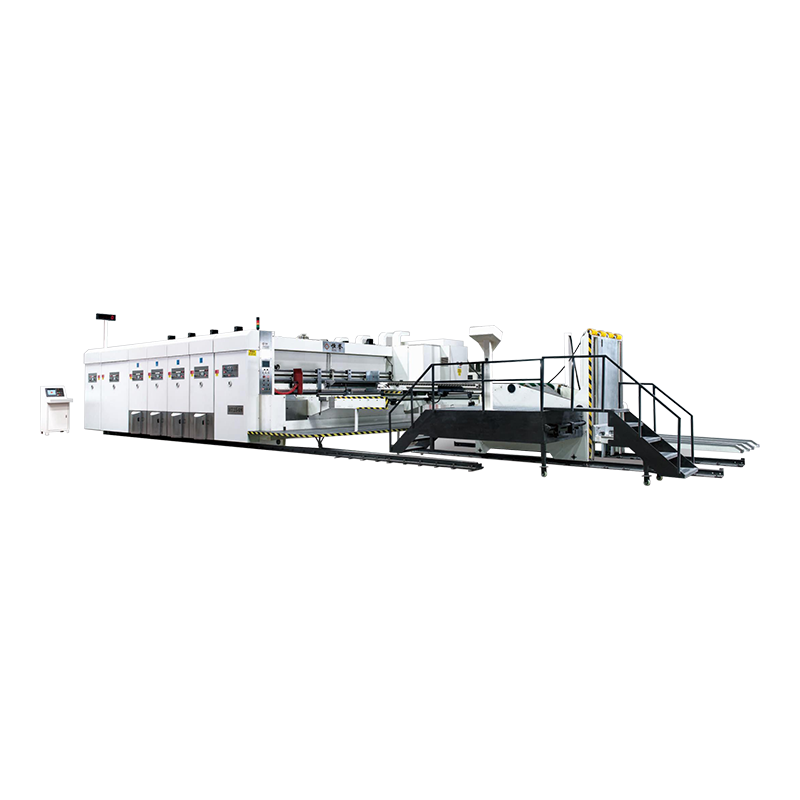

The carton box printing linkage line is an integrated system designed to streamline the production of printed carton boxes. This system combines multiple processes, including printing, cutting, folding, and gluing, into a single automated line, significantly improving efficiency and reducing manual intervention. The printing linkage line is equipped with advanced technologies such as high-resolution printers, precision cutting tools, and automated folding mechanisms, ensuring consistent quality and accuracy in every carton produced. It is widely used in industries that require high volumes of custom-printed cartons, such as food packaging, electronics, and consumer goods. The integration of these processes not only speeds up production but also minimizes material waste and errors. By adopting a carton box printing linkage line, manufacturers can achieve higher output rates, meet tight deadlines, and maintain competitive advantage in the market.

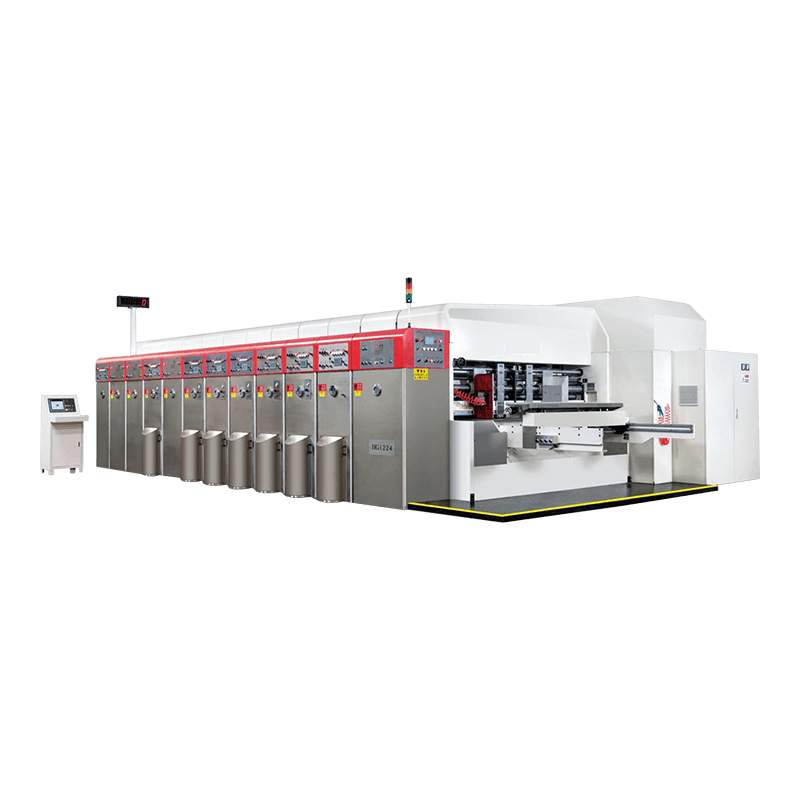

High Definition Computerized Flexo Printing Die Cutting Machine

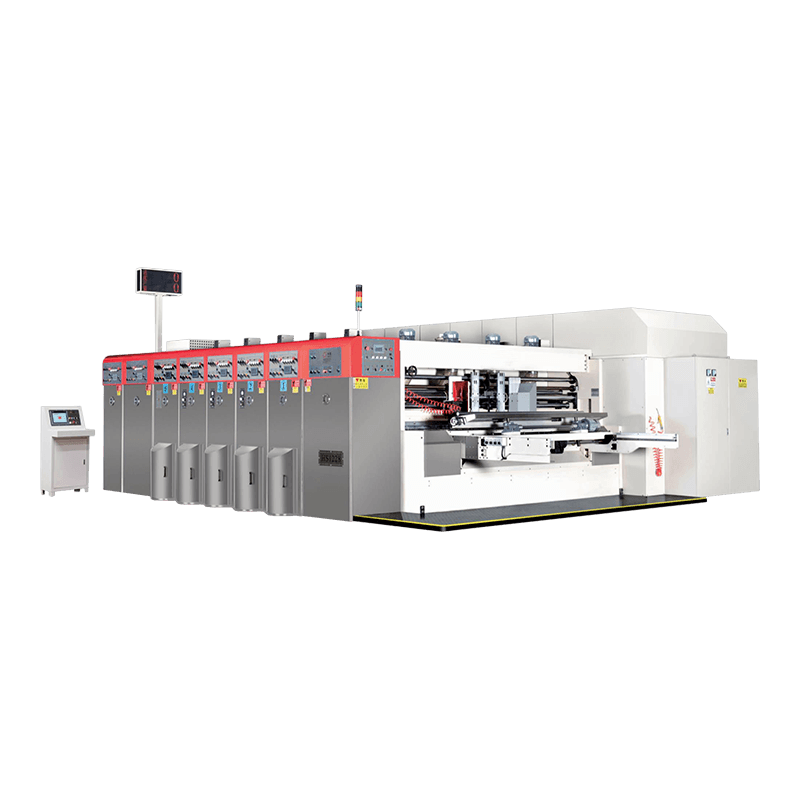

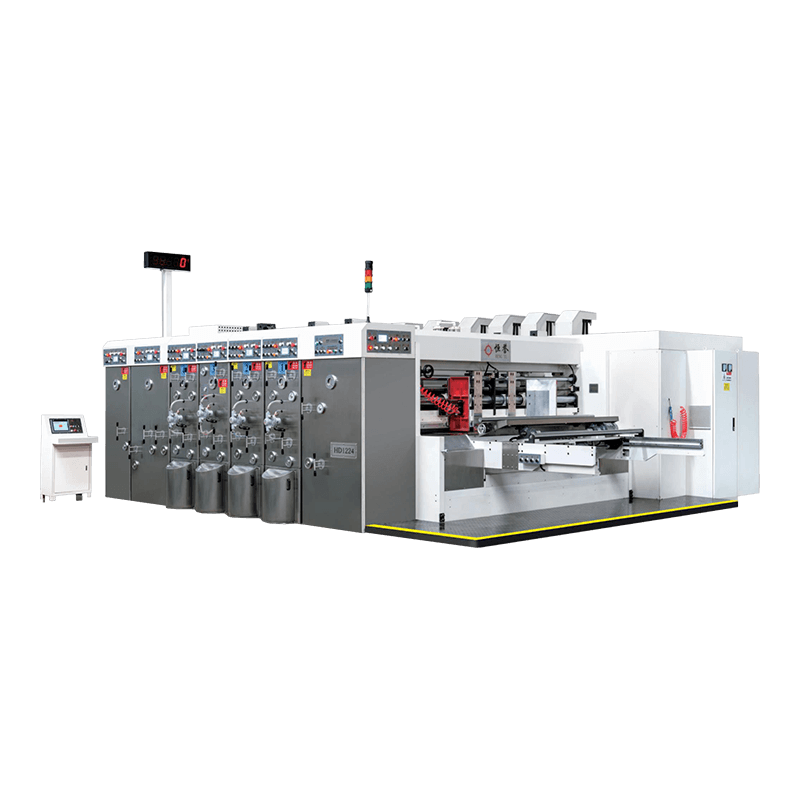

Computer Control Large size Flexo Printing Slotting Die Cutting Machine

Enterprise establishment

Employees

As industries shift towards efficient and high-quality packaging solutions, the demand for advanced printing technologies, such as carton box printing linkage lines, has increased significantly. These systems are essential for printing on corrugated cartons, cardboard, and other packaging materials. This guide will delve into the diverse applications, key advantages, and features of flexo printers, corrugated carton printers, and custom cardboard printing solutions, with a focus on how manufacturers can benefit from investing in such advanced machinery.

A carton box printing linkage line is a fully integrated system designed for printing on corrugated and cardboard packaging materials. This equipment links various stages of the printing process, such as the feeding, printing, and drying, into a seamless workflow. The machine operates in conjunction with other units like flexo printers to ensure that high-quality prints are applied efficiently and consistently to carton boxes.

This system allows manufacturers to print detailed designs, logos, barcodes, and other essential information directly onto the surface of corrugated boxes or other types of packaging materials. Whether you're dealing with large volumes of packaging or custom designs, this linkage line can automate and streamline the process, enhancing productivity.

Advantages:

Increased automation of the printing process

Consistent, high-quality results

High-speed operation for large-scale production

Versatility in handling various sizes of carton boxes

Why Buy This? For businesses looking to improve packaging aesthetics and functionality, investing in a carton box printing linkage line is a smart move. It reduces manual labor, minimizes errors, and boosts production efficiency.

The flexo printer is one of the primary components of a carton box printing linkage line. It uses flexible relief plates to transfer ink to the surface of a material, such as cardboard or corrugated paper. This type of printing is especially useful for custom cardboard printing as it allows for sharp, clean images, even on rough surfaces like corrugated material.

Advantages of Flexo Printing in Carton Boxes:

High-Speed Printing: Flexo printers are capable of running at high speeds, making them ideal for mass production of corrugated cartons.

Versatility: Flexo printing can handle various materials, including corrugated, paper, and even plastics, making it great for custom cardboard printing.

Cost-Effectiveness: The process is relatively cost-effective, especially when printing large quantities.

Why Buy This? Flexo printing is a great solution for manufacturers who need fast, reliable printing with minimal setup time. Whether for regular designs or custom cardboard printing, flexo printers offer the flexibility and speed necessary for modern production environments.

A corrugated carton printer is a specialized printer designed to print directly onto corrugated material. These printers ensure that printed images are clear and vibrant, even on the uneven surfaces of corrugated cardboard. This technology can print high-quality graphics, text, logos, and barcode information, all while maintaining the integrity of the cardboard.

Corrugated carton printers typically feature multiple color capabilities, advanced drying systems, and precision printing technology that allows for high-definition prints without compromising the strength of the cardboard.

Advantages:

Durability: Prints stay intact even after the carton is folded, stacked, or shipped.

High Definition: Even intricate designs and fine text are printed clearly.

Efficiency: Optimized for continuous printing on large quantities of cartons.

Why Buy This? A corrugated carton printer is an outstanding investment for companies that need to ensure their packaging reflects the quality of their brand. The durability and clarity of the print provide a professional, polished look that enhances product presentation.

Custom cardboard printing is an outstanding option for businesses that need packaging that stands out. Whether it's for branding, promotional purposes, or simply to meet unique packaging specifications, custom cardboard printing provides a high level of flexibility in terms of design, size, and color. Using carton box printing linkage lines with specialized flexo printers or corrugated carton printers, manufacturers can produce a wide range of custom packaging options for their products.

Advantages of Custom Cardboard Printing:

Branding Opportunities: Custom printing allows businesses to include logos, brand names, and other personalized designs on their packaging, enhancing brand visibility.

Unique Designs: Unlike generic boxes, custom-printed cartons can feature eye-catching designs that draw consumer attention.

Tailored Specifications: Custom printing allows you to cater to specific product needs, whether that's for retail, shipping, or gift packaging.

Why Buy This? For companies that prioritize differentiation in the marketplace, custom cardboard printing adds a professional touch that communicates the brand's value and commitment to quality.