Introduction

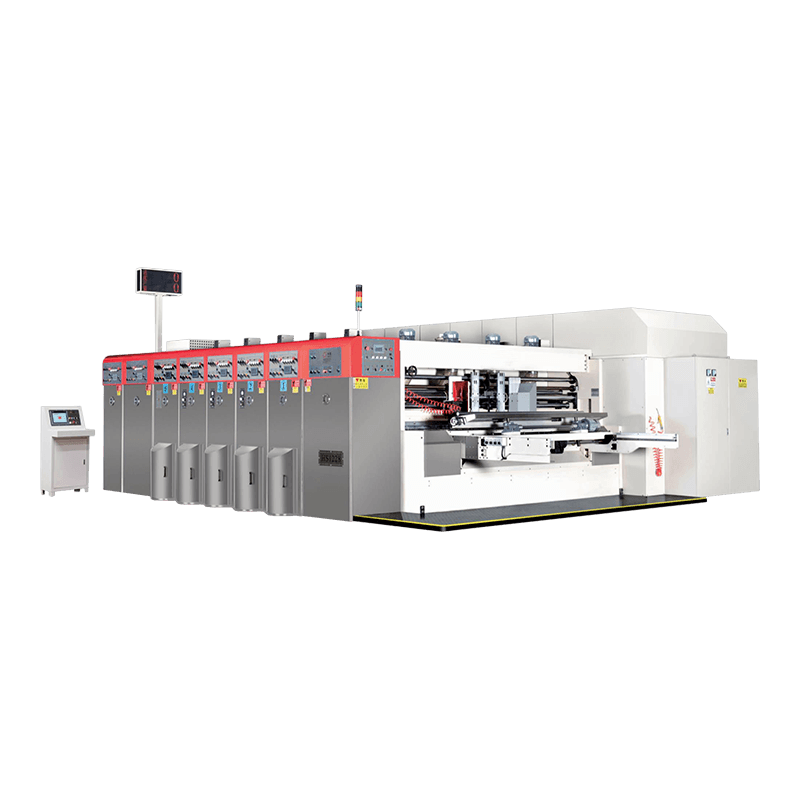

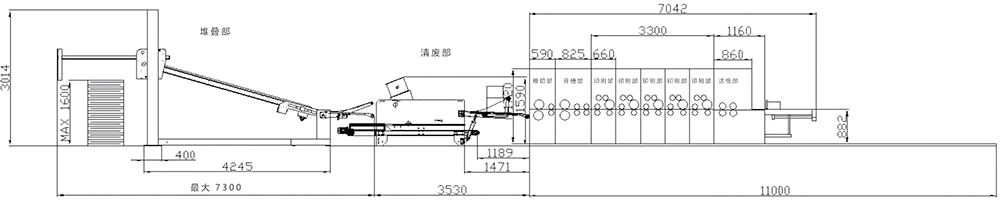

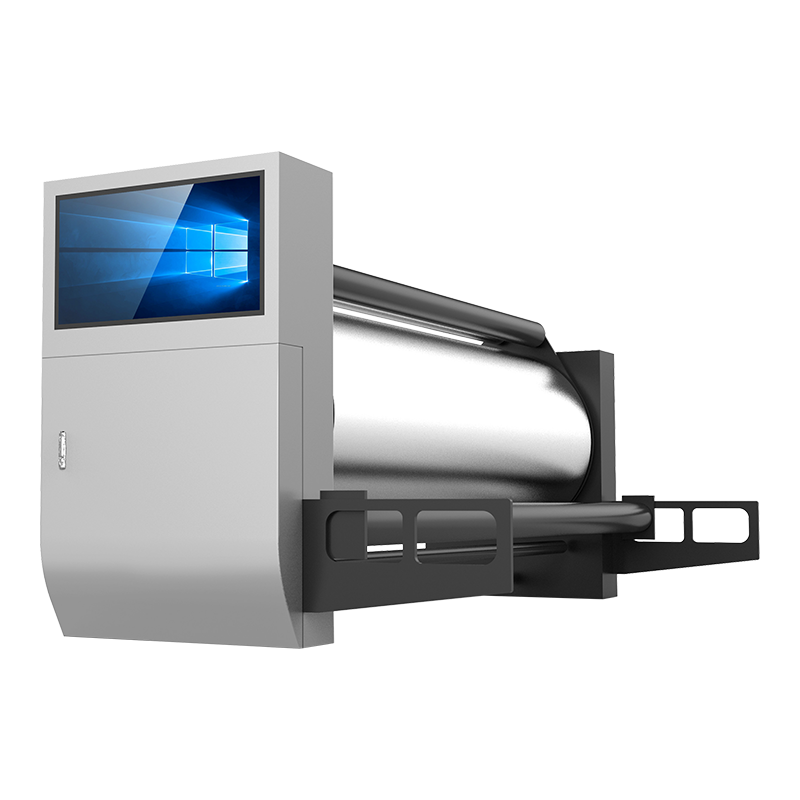

The Computerized Flexo Printing Slotting Die Cutting Machine is designed with advanced technology from Europe and the United States. It features a mobile unit and vacuum adsorption printing for efficient operation. The machine can be equipped with hot air, infrared, UV, and independent drying devices, along with a doctor blade for full-screen printing. It is controlled by an independent computer touch screen with PLC, allowing for easy storage of commonly used orders, rapid version changes, and quick ink wash to reduce ink wastage. Other features include an automatic oil balancing device, die-cutting frequency compensation, and optional remote maintenance for fast troubleshooting.

Main Unit

1. Feeder Unit:

Equipped with a Sun Automation Lead Edge Feeder, the machine ensures precise and stable feeding through strong vacuum transfer.

A dust removal system with a brush and segmented vacuum sheet cleaner is included.

The self-locking system allows automatic adjustment of the feeding roll gap. Motorized and PLC-controlled side guides ensure accurate alignment.

The main motor is protected from starting if the units are not fully closed and locked.

2. Printer Unit with Vacuum Transfer:

The printer unit features a pneumatic clutch on the anilox roll to:

(a) synchronize with the main motor during printing,

(b) stop when idle,

(c) reduce the risk of damage to the rubber and anilox rolls,

(d) allow washing of unused units while running.

The transverse register is digitally controlled by motor and PLC, with an adjustment range of ±10mm.

The cleaning function is automated for thorough ink recycling, and the printer resets automatically after cleaning.

An optional Doctor-Blade Inking System is available for improved ink management.

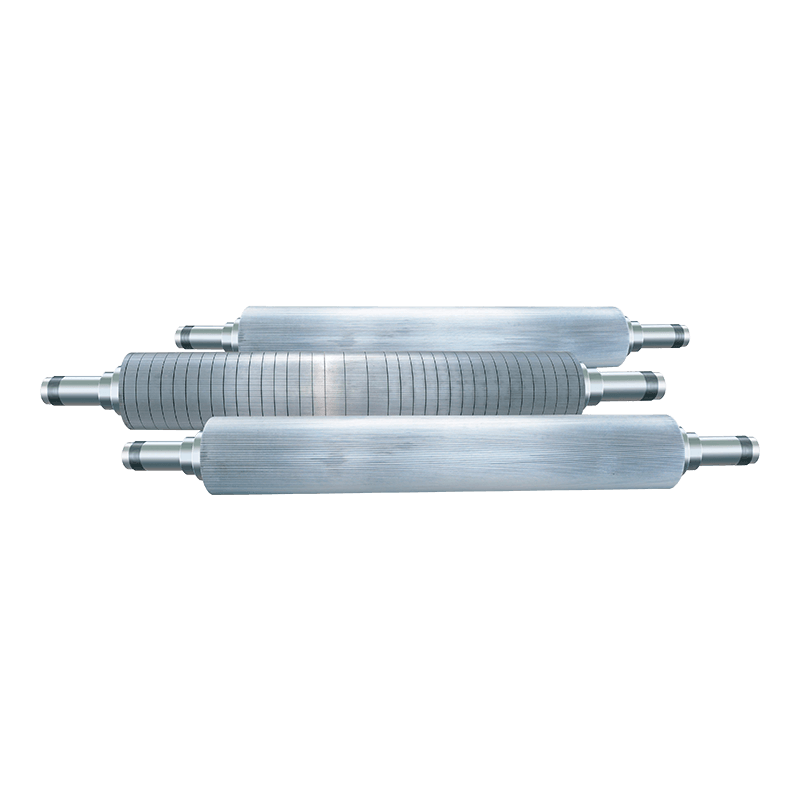

3. Slotter Unit:

The slotting unit features an internal gear to adjust the height of the carton box and prevent lubricating oil from spilling onto the paperboard.

The upper and lower bosses are coupled to keep the slotting knives aligned, which helps extend the machine's service life.

The slotting register and carton box height are digitally controlled by motor and PLC.

Motorized controls adjust the slotting boss caliber.

A protective device prevents the slotting knife from crashing when adjusting the carton box height.

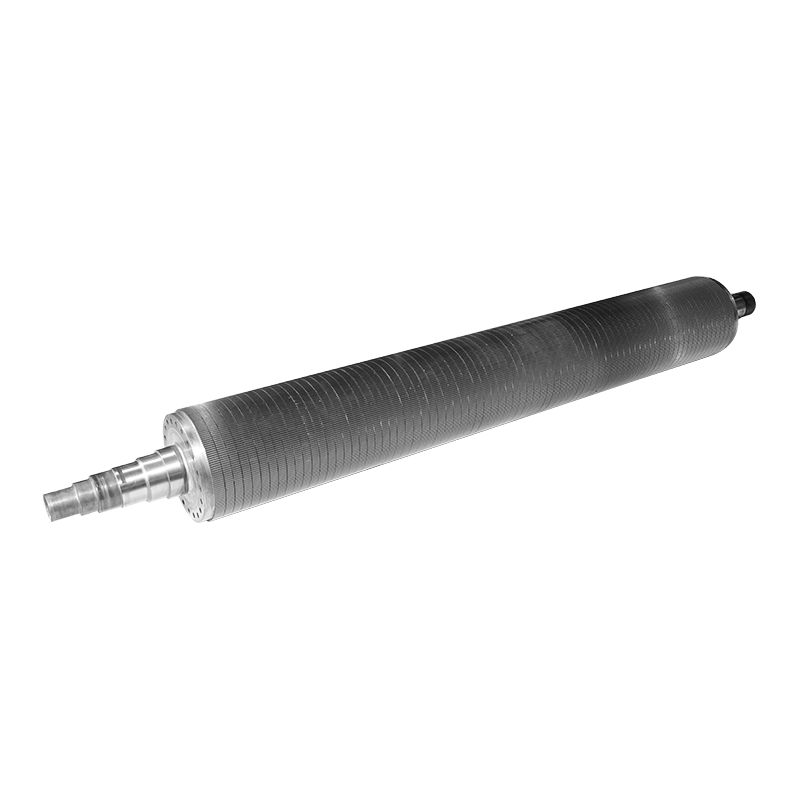

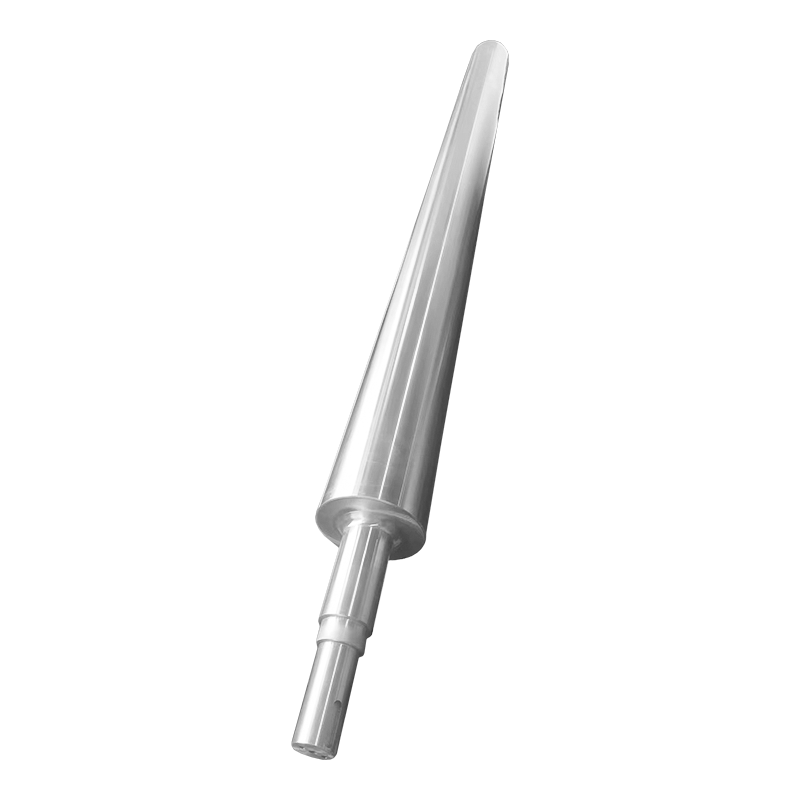

4. Die-Cutting Unit:

The die-cutting unit includes side-to-side oscillation of the anvil drum (50mm) for precise die-cutting.

The die-cut cylinder lateral register is digitally controlled by motor and PLC, with a range of ±10mm.

An independent motor compensates the anvil rubber roller speed, with a compensation range of ±3mm.

An anvil trimmer maintains a flat and smooth surface on the anvil covers for High quality performance.

English

English  Español

Español  Português

Português  عربى

عربى