Introduction

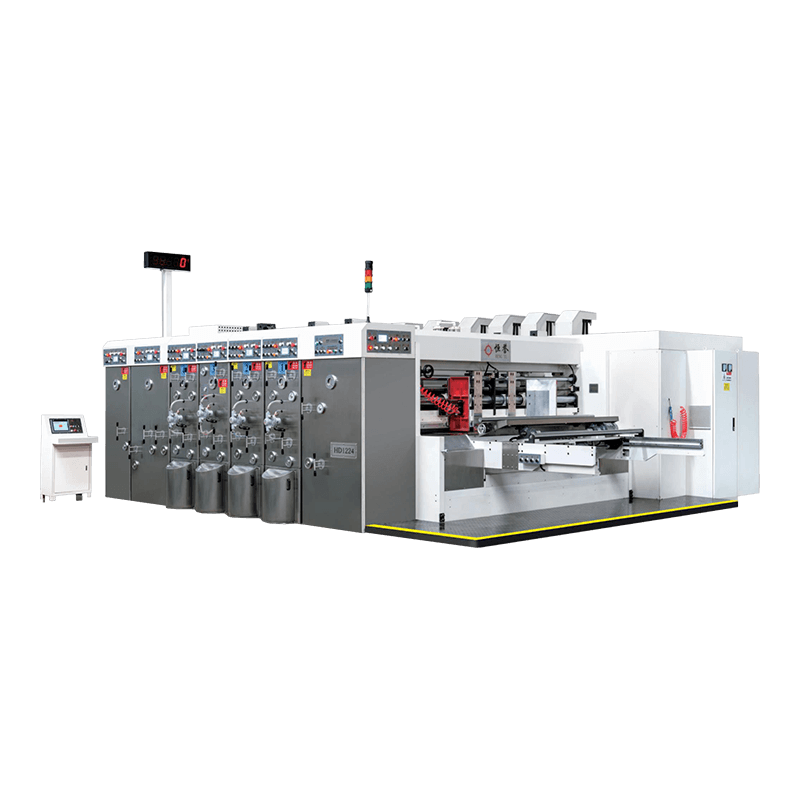

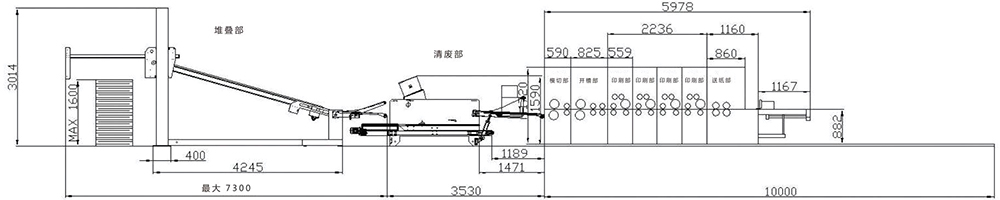

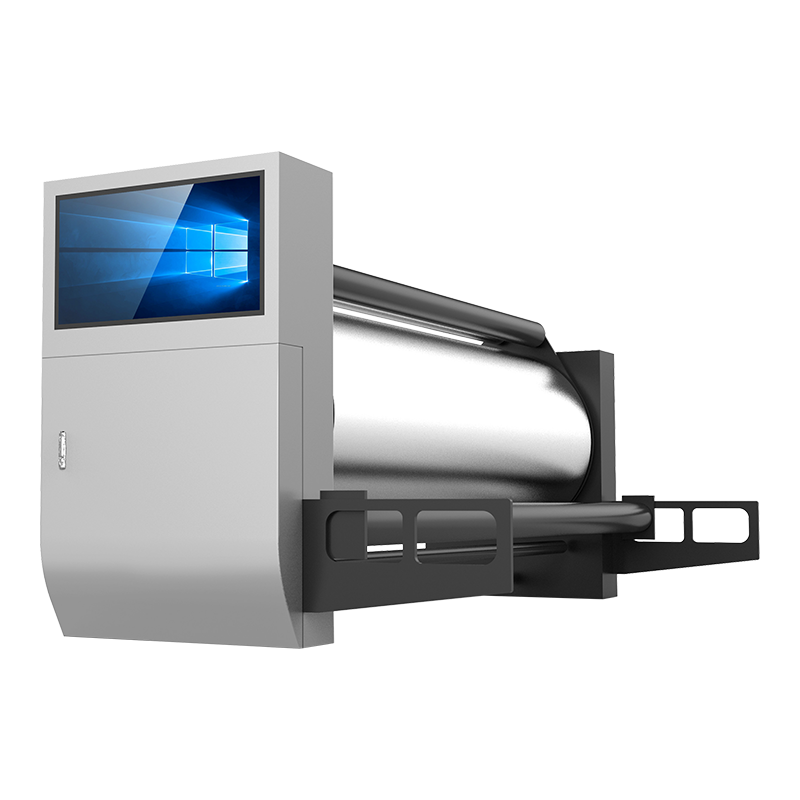

The Auto High-Speed Flexo Printing Slotting Die-Cutting Machine is designed for high-efficiency packaging production. Featuring a European and U.S. design concept, the machine operates with a roller-to-roller transfer printing system. It incorporates an independent computer touch screen with PLC control, allowing users to store frequently used orders and quickly switch between production runs.

Main Unit

1. Feeder Unit:

Equipped with a Sun Automation Lead Edge Feeder, the system provides precise and stable paperboard feeding with a strong vacuum transfer. The vacuum blower fan is controlled by a variable frequency drive, enabling easy adjustment to match different paperboard sizes. A dust removal system with brush and vacuum sheet cleaner ensures cleanliness during operation. The self-locking system makes it easy to adjust feeding rolls, while PLC control manages the side guides for accurate feeding.

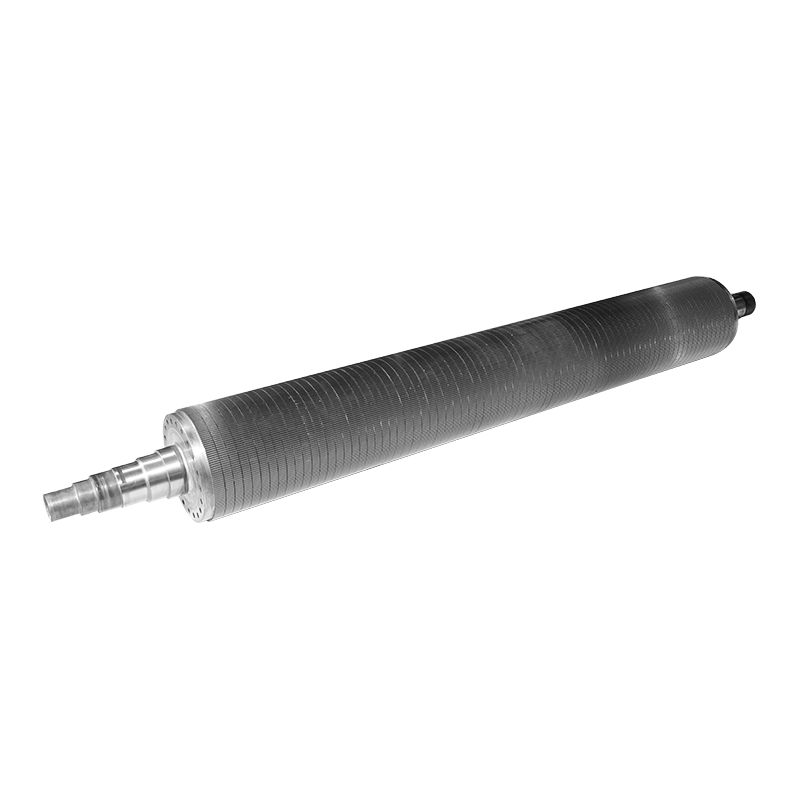

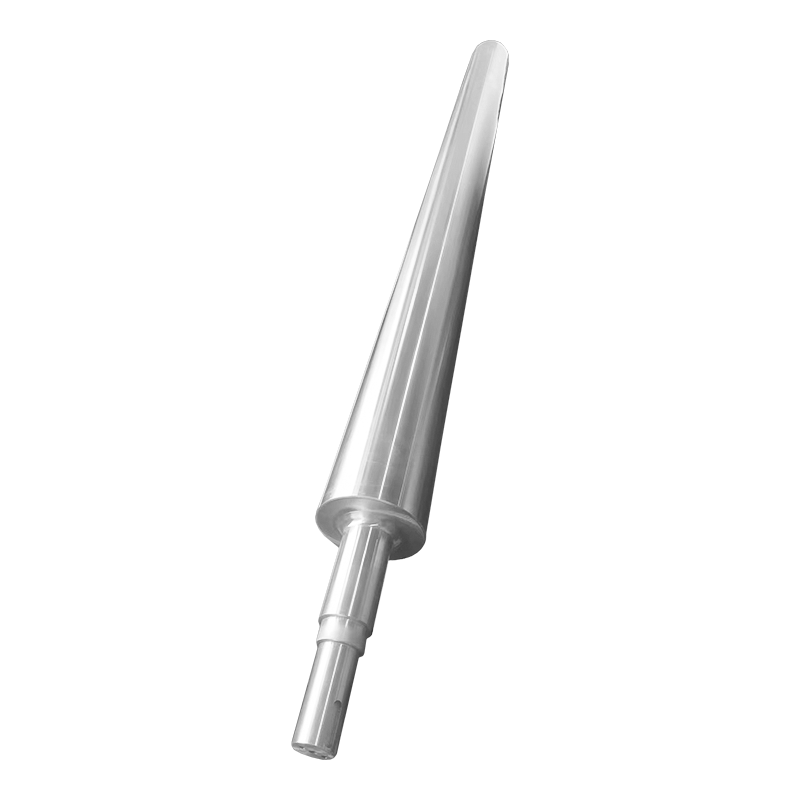

2. Printer Unit:

The anilox roll uses a pneumatic clutch to synchronize with the main motor during printing and stop when idle. The transverse register is digitally controlled for accurate alignment. The printer unit also features a self-locking mechanism for impression roll and anilox roll adjustment. An optional doctor-blade inking system is available for more precise ink application.

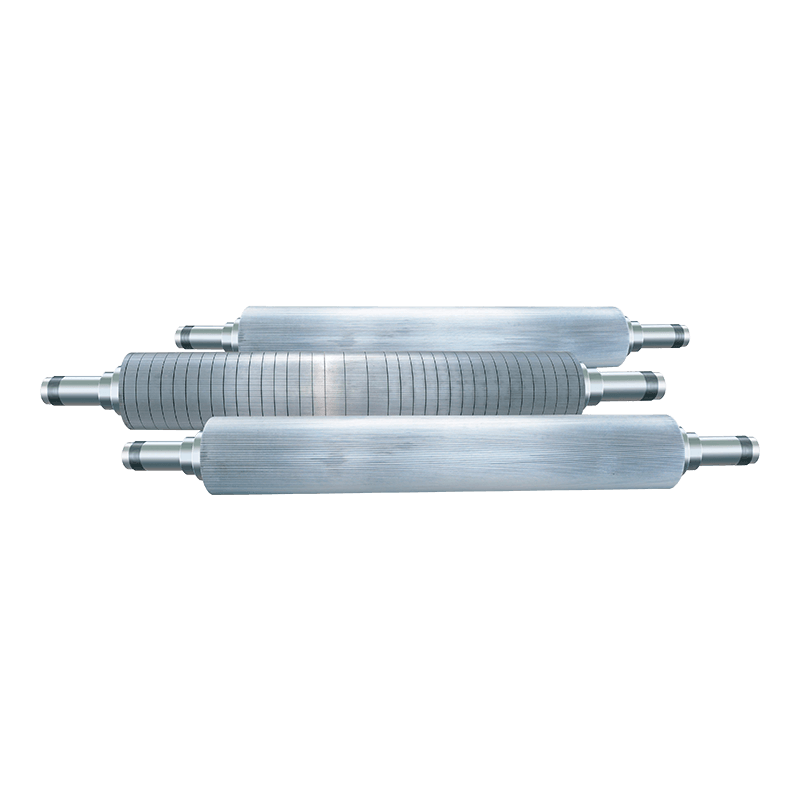

3. Slotter Unit:

The slotter unit uses an internal gear to adjust the height of the carton box, preventing oil leakage. The pre-creasing rolls, creasing rolls, and slotting bosses are digitally controlled by motor and PLC, ensuring precise slotting and creasing. The slotting boss adjustment is also self-locked for easy calibration.

4. Die-Cutter Unit:

Featuring side-to-side oscillation of the anvil drum, the die-cutting unit ensures even pressure distribution. The die-cut cylinder lateral register is digitally controlled for accuracy, and the anvil rubber roller speed is compensated by an independent motor to maintain consistent cutting quality.

English

English  Español

Español  Português

Português  عربى

عربى