More Information About Full Computer Control Paste Box Production Line What You Need To Know

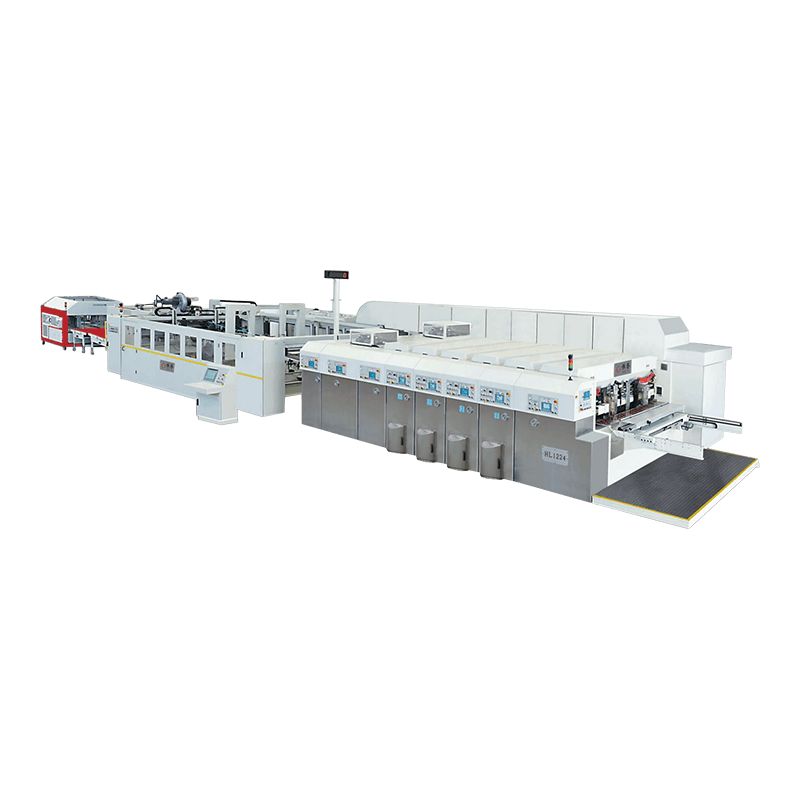

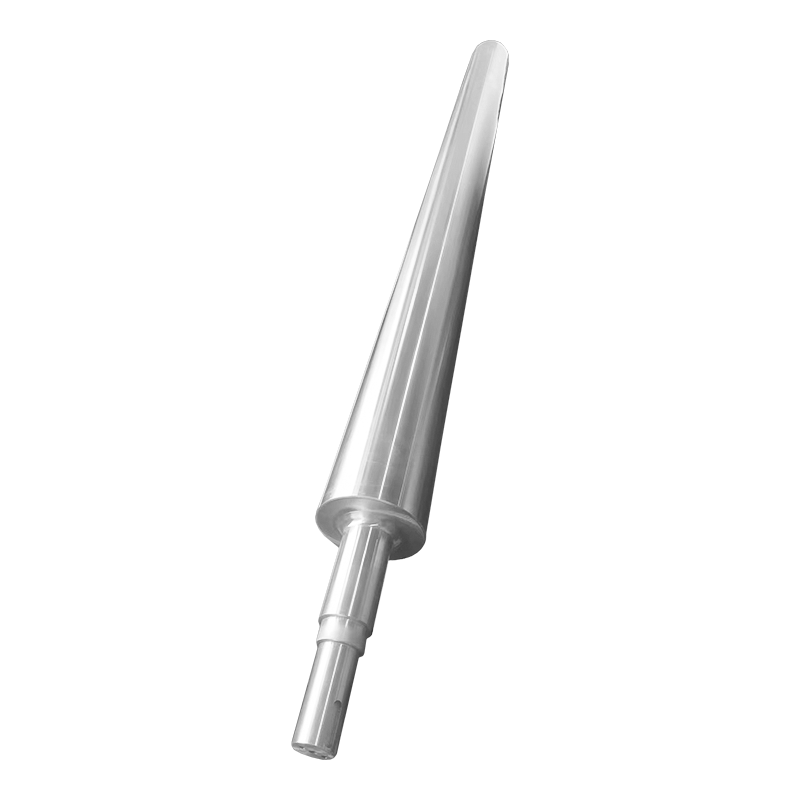

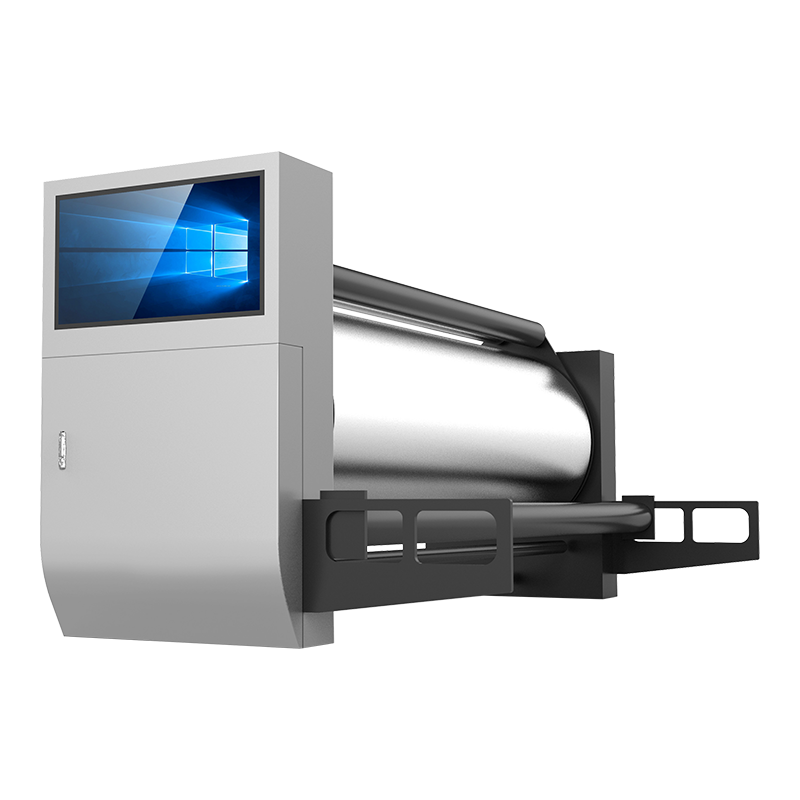

As a professional manufacturer of advanced packaging machinery, Zhejiang Yonghui Roller Co., Ltd. introduces its effective Full Computer Control Paste Box Machine—a fully automated solution designed to streamline corrugated box production with unmatched precision and efficiency. This Paste Box Production Line integrates intelligent glue application, precise folding, and high-speed stacking into one seamless system, making it the ideal choice for modern packaging facilities seeking to boost output while reducing labor costs.

Why Choose Our Intelligent Paste Box Machine?

1. Fully Automated Operation for improve Efficiency

Our Paste Box Production Line eliminates manual handling with:

- Robotic box folding & gluing – Ensures consistent adhesive application every time.

- Auto-feeding system – Processes up to 120 boxes per minute without operator intervention.

- Smart alignment sensors – Detects and corrects misaligned flaps in real-time.

2. Precision Glue Control for good Bonding

The Full Computer Control Paste Box Machine features:

- Programmable glue nozzle system – Adjusts adhesive volume based on box size and material.

- Waste-free glue application – Reduces adhesive consumption by 20-30% compared to manual methods.

- Quick-drying adhesives compatibility – Works with PVA, starch-based, and hot melt glues.

3. Smart Production Monitoring & Data Analytics

- Touchscreen HMI – Allows operators to adjust settings, track output, and diagnose issues instantly.

- Cloud-connected performance tracking – Monitors OEE (Overall Equipment Effectiveness) for proactive maintenance.

- Error self-correction – Automatically pauses production if defects are detected.

Key Advantages Over Conventional Machines

① 50% Higher Productivity

Our Paste Box Machine runs continuously at high speeds without fatigue, doubling daily output compared to semi-automatic systems.

② 60% Labor Cost Reduction

Fully automated operation means 1 operator can manage what previously required 3-4 workers.

③ Unmatched Consistency

The Full Computer Control Paste Box Machine produces boxes with ±0.5mm dimensional accuracy, eliminating rejects due to poor folding or glue gaps.

Who Should Invest in This System?

High-Volume Corrugated Box Manufacturers

Ideal for plants producing 50,000+ boxes daily for e-commerce, food packaging, or logistics.

Packaging Facilities Using Recycled Materials

Automated glue adjustment compensates for paper thickness variations common in recycled board.

Companies Seeking Industry 4.0 Integration

Our Paste Box Production Line easily connects to MES/ERP systems for smart factory implementation.

Technical Specifications

Max. Production Speed: 120 boxes/min

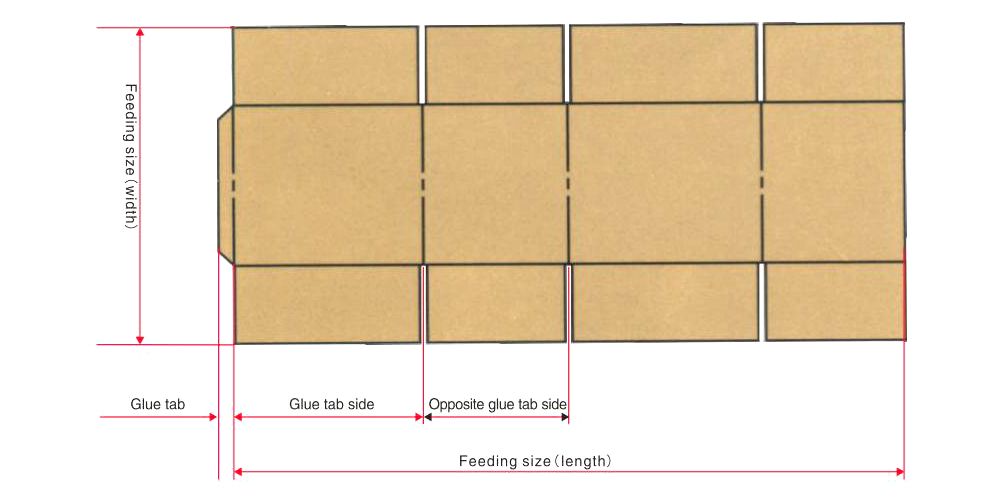

Box Size Range: 150-800mm (L), 100-600mm (W)

Glue Type: PVA, Starch, Hot Melt

Power Consumption: 15kW (energy-saving mode available)

Control System: Siemens PLC + 10 Touchscreen

Real-World Performance Gains

A European packaging converter achieved:

- 40% faster order fulfillment after installing our Paste Box Machine

- 15% material savings from precise glue application

- ROI in 14 months through labor and waste reduction

Customization Options Available

We offer tailored configurations for:

- Extra-large box handling (up to 1,200mm length)

- Specialty adhesives (waterproof, freezer-grade)

- Integration with existing printing/die-cutting lines

Experience the Future of Box Production

Zhejiang Yonghui's Intelligent Automatic Glue Making Machine System represents the next evolution in Paste Box Production Line technology. With its Full Computer Control Paste Box Machine precision and Industry 4.0 capabilities, it's the smartest investment for packaging manufacturers looking to:

Slash production costs

Boost output quality

Future-proof their operations

The Full Computer Control Paste Box Production Line is an advanced, fully automated system designed for the high-efficiency manufacturing of paste boxes. Integrated with intelligent computer control technology, this production line ensures precise coordination of feeding, gluing, folding, forming, and stacking processes. It significantly improves production speed and accuracy while reducing manual labor and material waste. Ideal for large-scale packaging operations, it supports customizable box sizes and materials, delivering consistent quality and operational stability.

Ready to upgrade your production? Contact our engineers today for a free consultation.

English

English  Español

Español  Português

Português  عربى

عربى