Introduction

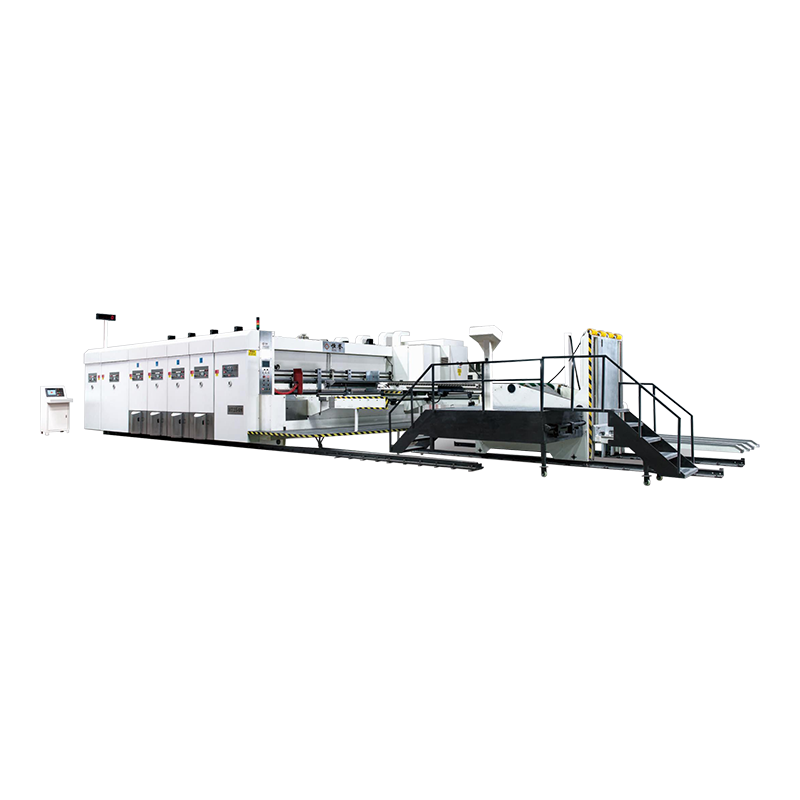

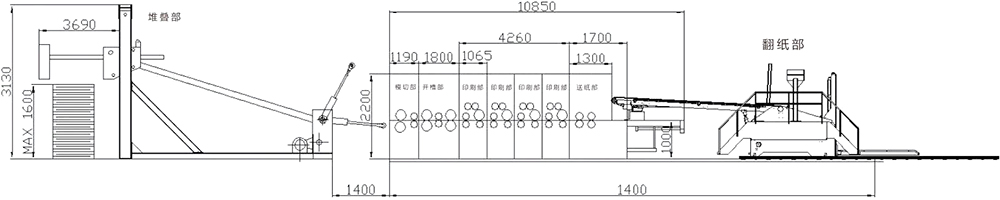

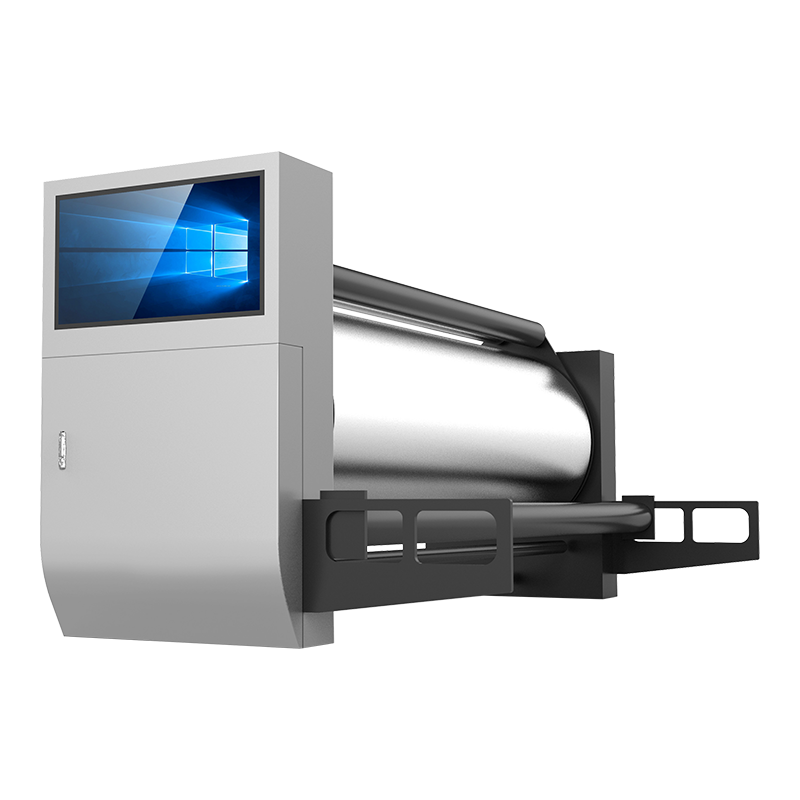

This Computer Control Large size Flexo Printing Slotting Die Cutting Machine integrates advanced design concepts from Europe and the United States, featuring a mobile unit with roller-to-roller transfer printing. It is controlled by an independent computer touch screen PLC and can store frequently used orders. The machine supports fast version changeovers, quick ink cleaning, and ink-saving functions, ensuring High quality performance. Additional features include an automatic oil balancing system, die-cutting frequency compensation, and optional remote maintenance for rapid troubleshooting. It is particularly suitable for large-size carton printing and can be equipped with a feeder for enhanced productivity.

Main Unit

1. Feeder Unit:

Sun Automation Lead Edge Feeder with strong vacuum transfer for precise and stable feeding.

Variable frequency drive for the vacuum blower fan, allowing adjustment of suction power to match various paperboard sizes.

Dust removal system with brush and segmented vacuum sheet cleaner.

Self-locking system for adjusting the feeding roll gap. Motorized and PLC-controlled side guides.

Main motor protection ensures it does not start unless the units are fully closed and locked.

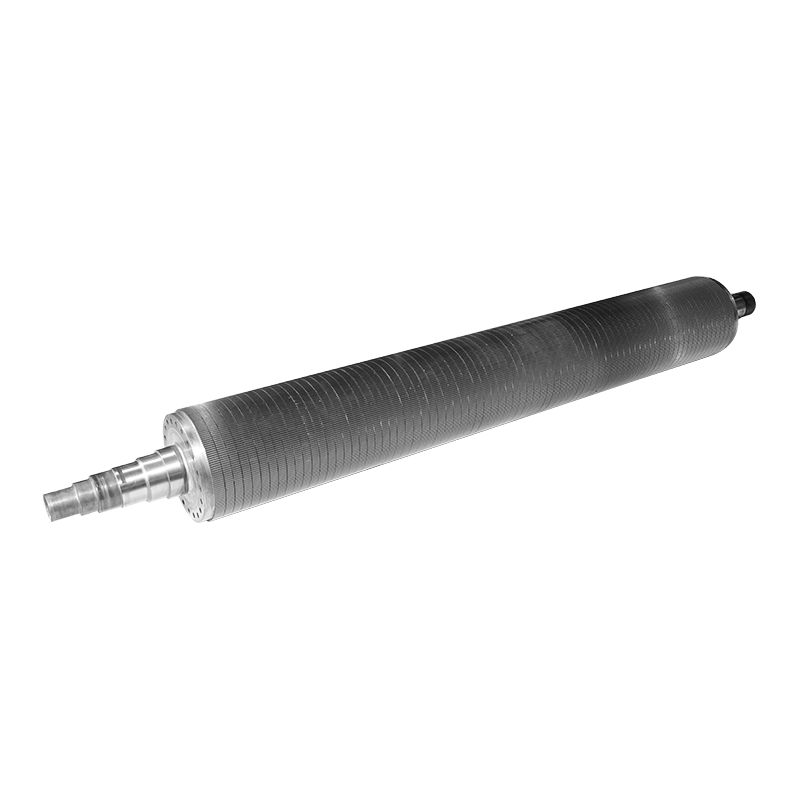

2. Printer Unit:

Pneumatic clutch on the anilox roll for synchronization with the main motor during printing and for stopping when not in use.

Digital printing register and transverse register controlled by motor and PLC (±10mm).

Automatic cleaning function for thorough ink recycling, with automatic reset after cleaning.

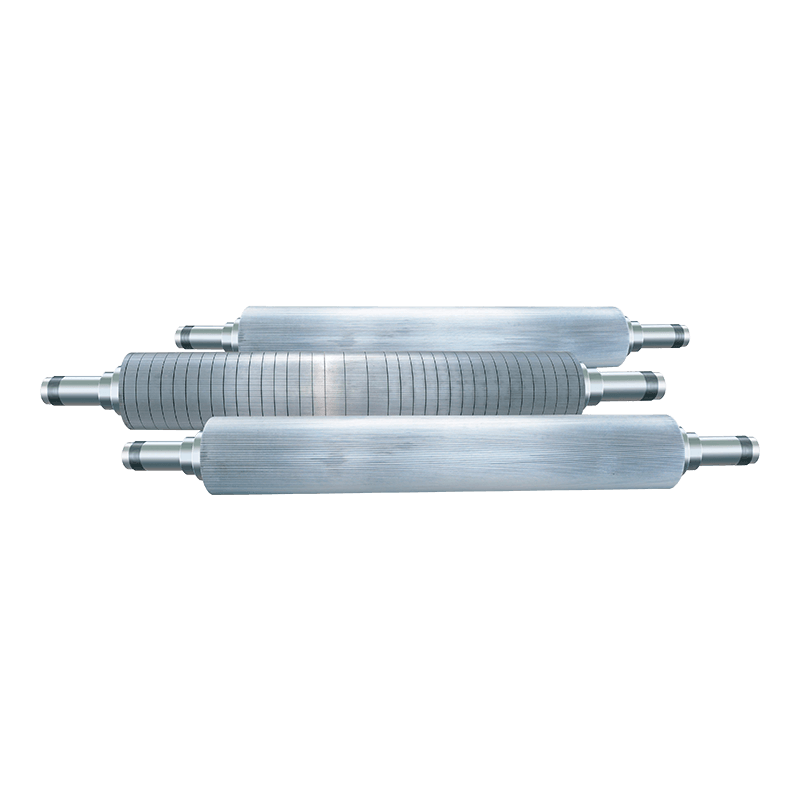

3. Slotter Unit:

Internal gear to adjust carton height and prevent oil spillage onto paperboard.

Upper and lower bosses keep the knives aligned during movement, extending the service life.

Digital control of slotting register and carton height, motorized transverse movement for pre-creasing rolls, creasing rolls, and slotting bosses.

Motorized control of the slotting bosses' caliber.

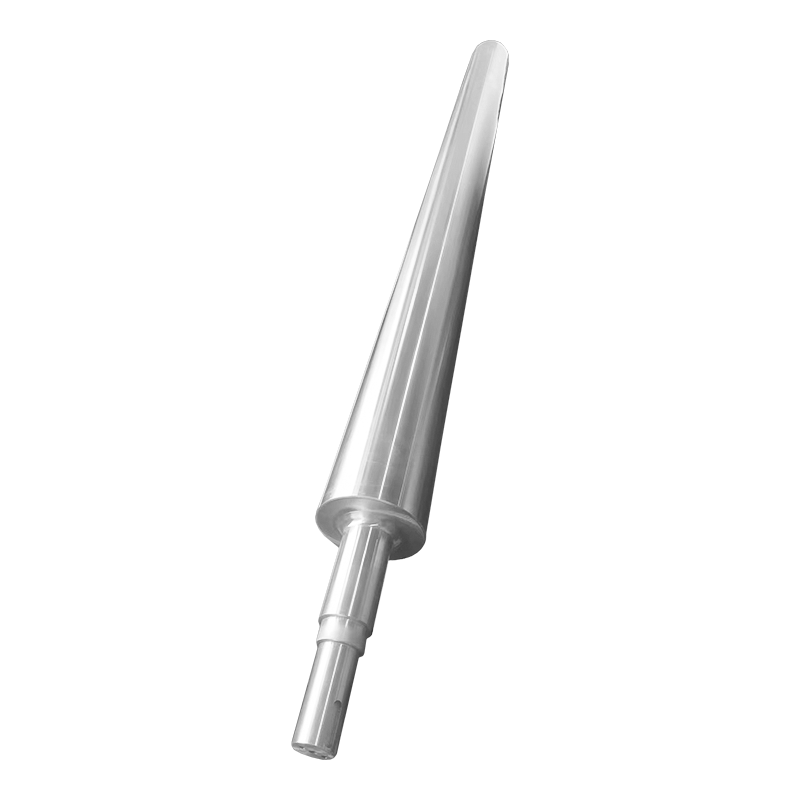

4. Die-Cutter Unit:

Side-to-side oscillation of the anvil drum (50mm) to extend the life of the anvil cover.

Digital control of die-cutting register and cylinder lateral register (±10mm) by motor and PLC.

Motorized caliper adjustment between the anvil roll and die drum.

Auto Speed Compensation system with independent motor-driven rubber roller speed compensation (±3mm).

English

English  Español

Español  Português

Português  عربى

عربى