More Information About Corrugated Hydraulic Mill Roll Stand What You Need to Know

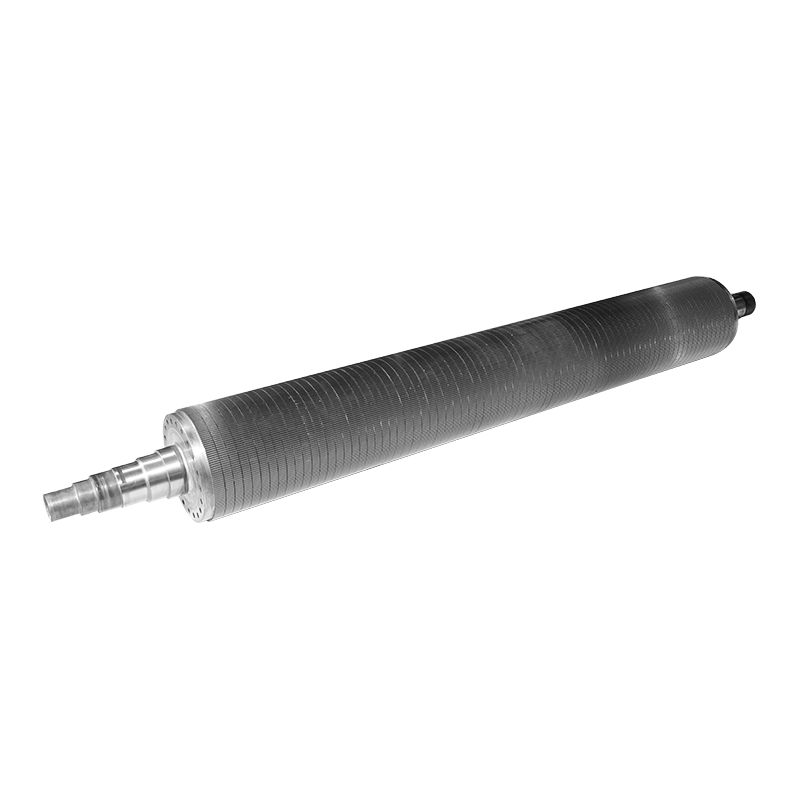

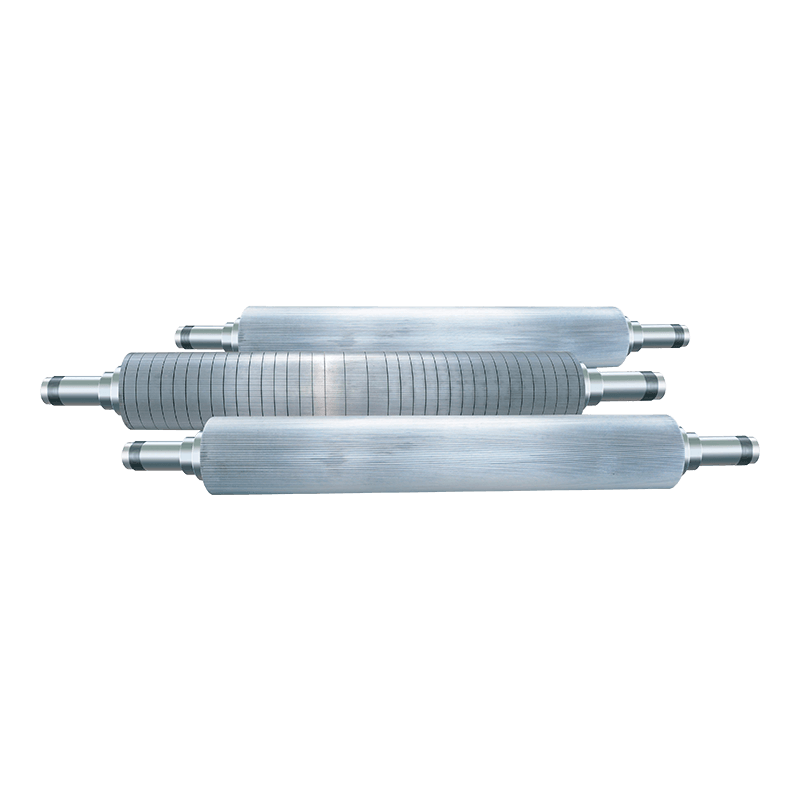

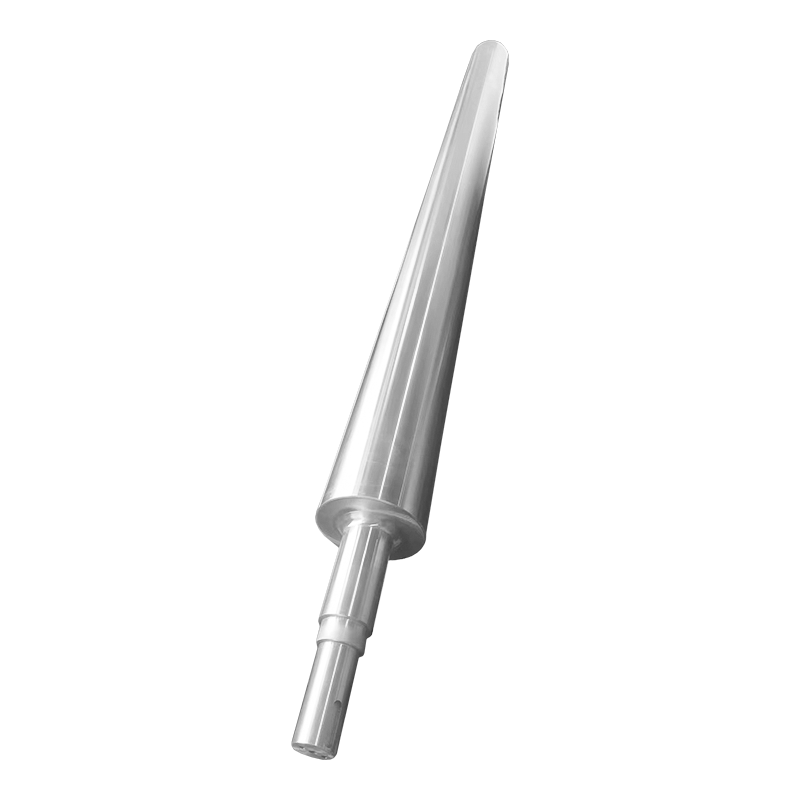

As a distinguished manufacturer based in China, Zhejiang Yonghui specializes in the production of high-quality pressure rolls, integral to the corrugated cardboard industry. Our expertise lies in crafting Mill Roll Stands and Corrugated Hydraulic Mill Roll Stands that are designed to enhance the efficiency and performance of your corrugated cardboard line.

Our Commitment to Quality and Innovation

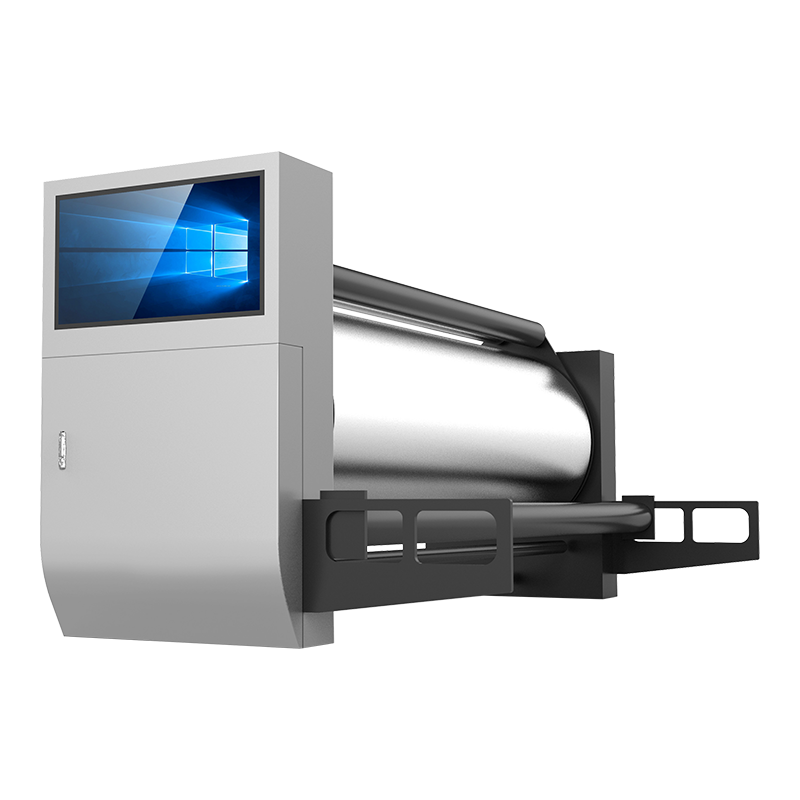

At Zhejiang Yonghui, we are dedicated to the continuous improvement of our Mill Roll Stands and Corrugated Hydraulic Mill Roll Stands. We understand that the heart of any corrugated cardboard line is the reliable and robust machinery that ensures consistent quality output. Our hydraulic mill roll stands are engineered to meet the stringent demands of modern paper converting, offering precision control and durability that are unmatched in the market.

Advantages of Zhejiang Yonghui's Mill Roll Stands

1. Precision Engineering: Our Mill Roll Stands are precision-engineered to provide uniform pressure across the entire width of the corrugated cardboard. This ensures consistent adhesive application and reduces the risk of wrinkles or other defects in the final product.

2. Durability and Longevity: Constructed from premium materials, our Corrugated Hydraulic Mill Roll Stands are built to withstand the rigors of continuous operation. This results in a longer service life and reduced downtime for maintenance.

3. Efficiency: The hydraulic system in our mill roll stands allows for quick and easy adjustments, which translates to faster production cycles and increased output. This efficiency is crucial for meeting the high demand for corrugated cardboard in various industries.

4. Customizability: Understanding that every production line has unique requirements, Zhejiang Yonghui offers customized Corrugated Hydraulic Mill Roll Stands. We work closely with our clients to tailor our products to fit their specific needs, ensuring good performance and compatibility with existing machinery.

5. Energy Efficiency: Our commitment to sustainability is reflected in the energy-efficient design of our Mill Roll Stands. By minimizing energy consumption, we help our clients reduce their environmental impact and operational costs.

Applications and Interests

Our Corrugated Hydraulic Mill Roll Stands are not just limited to the production of standard corrugated cardboard. They are also suitable for the manufacture of specialty boards used in packaging for fragile items, heavy goods, and even in the construction industry for formwork. The versatility of our mill roll stands caters to a wide range of interests, making them an attractive investment for businesses looking to diversify their product offerings.

Why Choose Zhejiang Yonghui for Your Corrugated Cardboard Line Needs?

When you choose Zhejiang Yonghui, you are partnering with a manufacturer that prioritizes innovation, quality, and customer satisfaction. Our Corrugated Hydraulic Mill Roll Stands are the result of years of experience and a deep understanding of the challenges faced by the corrugated cardboard industry. We are committed to providing solutions that not only meet but exceed the expectations of our clients.

Zhejiang Yonghui's Mill Roll Stands and Corrugated Hydraulic Mill Roll Stands are your key to unlocking the full potential of your corrugated cardboard line. With our focus on precision, durability, efficiency, customizability, and energy efficiency, we are confident that our products will be a valuable addition to your production process. Contact us today to discuss how our hydraulic mill roll stands can help take your business to new heights.

English

English  Español

Español  Português

Português  عربى

عربى