More Information About Pressure Rollers What You Need to Know

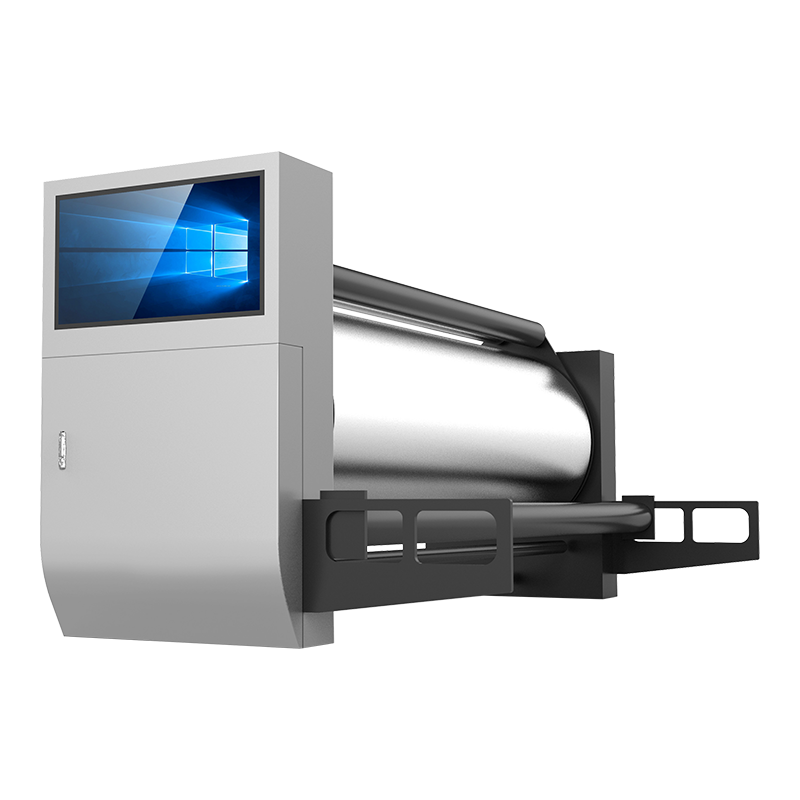

At Zhejiang Yonghui, we pride ourselves on being a professional manufacturer of pressure rolls for the corrugating industry. Our pressure rollers are designed to provide outstanding performance and durability for a range of corrugating applications, ensuring consistent and high-quality results for packaging manufacturers worldwide. In this article, we will highlight the advantages of our pressure rolls, their application in pressure roller machines, and the benefits they bring to businesses that rely on efficient and precise corrugated board production.

What Are Pressure Rolls and Why Are They Essential for Corrugating?

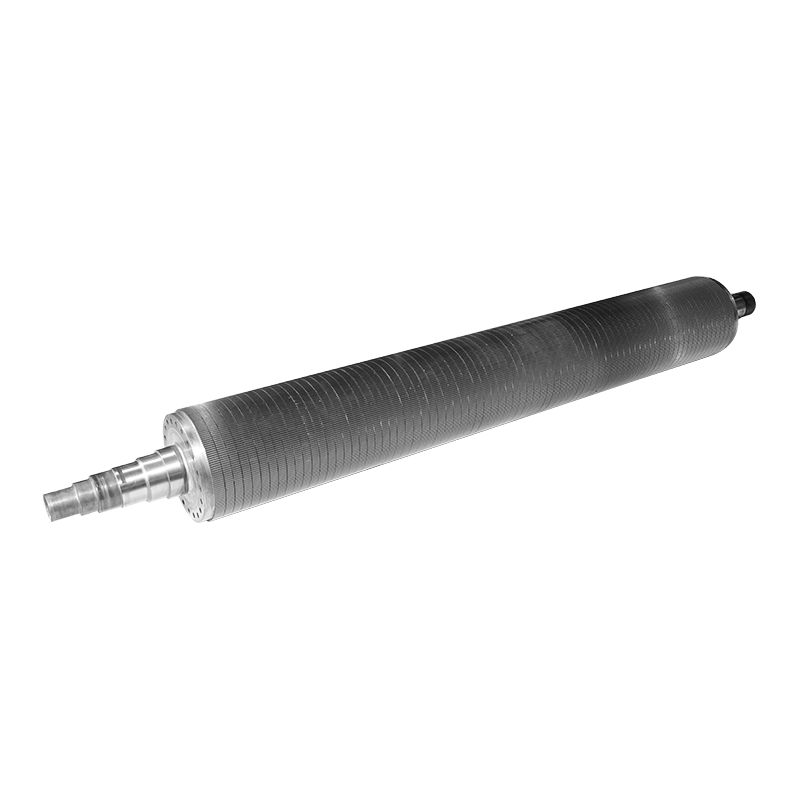

A pressure roll is a crucial component in the production of corrugated cardboard. These rolls are used to apply controlled pressure between the corrugating rolls and the linerboard during the manufacturing process. The pressure applied by the pressure roller machine ensures a strong bond between the medium and the liners, resulting in durable and sturdy corrugated board.

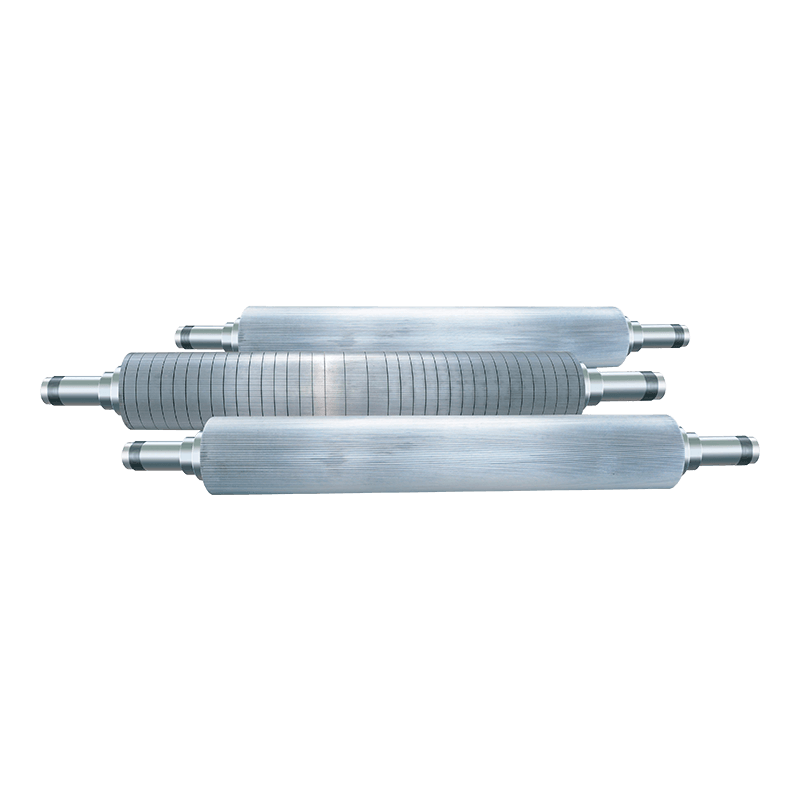

Our pressure rolls are engineered to provide consistent pressure and good performance, which directly contributes to the quality of the final product. Whether you're working with lightweight or heavy-duty corrugated boards, choosing the right pressure rolls is essential for achieving results.

Key Advantages of Zhejiang Yonghui Pressure Rolls

1. Durability and Longevity: At Zhejiang Yonghui, we use high-quality materials and precise manufacturing techniques to create pressure rolls that offer long-lasting durability. Our rolls are designed to withstand high pressure and continuous operation, ensuring minimal wear and tear over time.

2. Enhanced Bonding Strength: The primary function of pressure rolls is to ensure that the medium paper and liners are bonded tightly. By providing consistent pressure, our pressure roller machine helps produce corrugated boards with enhanced bonding strength, improving the performance of the final product.

3. Precision and Consistency: One of the challenges in corrugating is maintaining a consistent bond throughout the production process. Our pressure rolls are designed to provide even pressure across the entire width of the board, resulting in uniform quality across large batches. This precision minimizes defects and ensures that each board meets the required standards.

4. Efficiency in Production: The reliability of our pressure rolls contributes to a smoother and faster production process. With minimal downtime and reduced maintenance needs, our rolls help optimize the overall efficiency of your corrugating line, cause higher output and lower operational costs.

Applications of Pressure Rolls in the Corrugating Industry

Pressure rolls are used in various stages of corrugated board production. They are especially critical in the pressure roller machine, which serves as a pivotal device in the formation of high-quality corrugated board.

1. High-Pressure Grinding Rolls: These rolls are a crucial part of the grinding process, where high pressure is applied to ensure that the corrugating rolls and the medium paper are firmly bonded. The result is a smooth and even texture that enhances the strength of the final corrugated product.

2. Corrugating Lines: Whether you're producing single-wall or double-wall corrugated board, pressure rolls are essential for the smooth operation of corrugating lines. Our rolls are designed to meet the specific requirements of different types of board production, offering the flexibility to work with a variety of materials and thicknesses.

3. Packaging Industry: Packaging companies that rely on corrugated board for shipping products need pressure rolls that ensure the material is strong, durable, and able to withstand the rigors of transportation. Our pressure roller machine is engineered to produce boards that are both lightweight and robust, making them ideal for packaging applications.

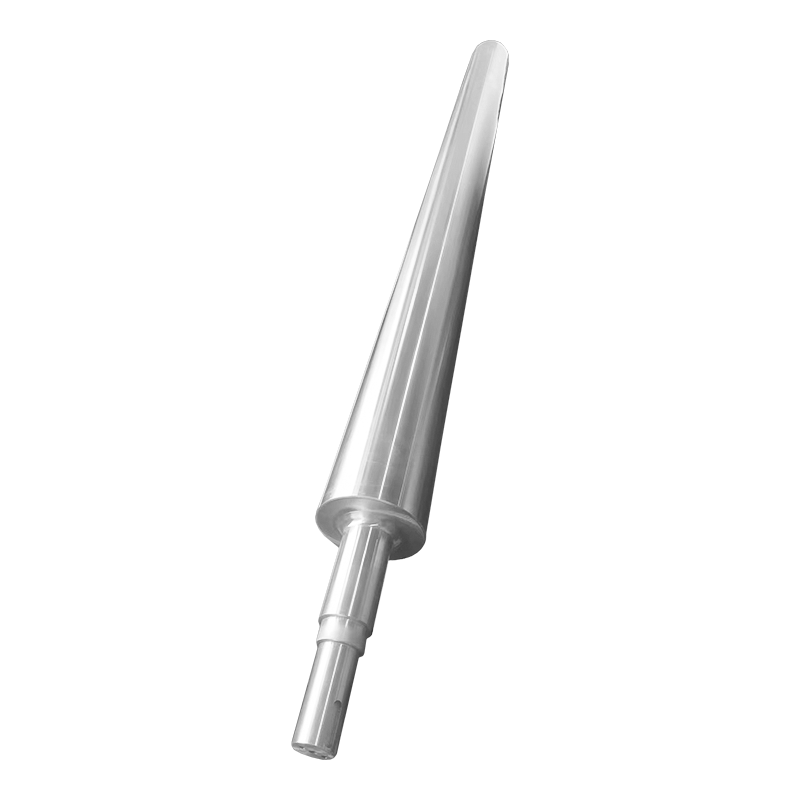

4.Custom Solutions for Special Requirements: In addition to standard pressure rolls, we also offer customized solutions tailored to meet unique client specifications. Whether you need rolls for specific materials or specialized machines, we can deliver custom-built solutions that align with your operational needs.

As a trusted manufacturer, Zhejiang Yonghui stands out in the pressure roll market due to our commitment to quality, performance, and customer satisfaction.

English

English  Español

Español  Português

Português  عربى

عربى