Product Features

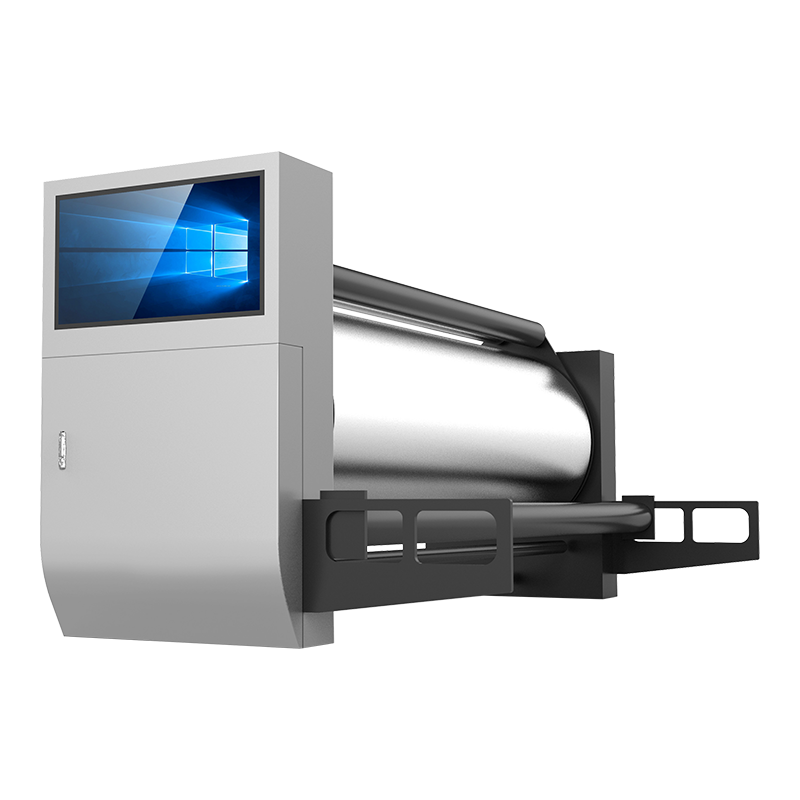

1. Preheating Cylinder Diameter: 1000mm;

2. Hot Cylinder Surface Plating Treatment: The cylinder body is slowly rotated by a motor, reducing friction between the base paper and the cylinder. This ensures an even temperature distribution and extends the service life, effectively protecting the base paper fibers. It also improves the compression index and operational speed;

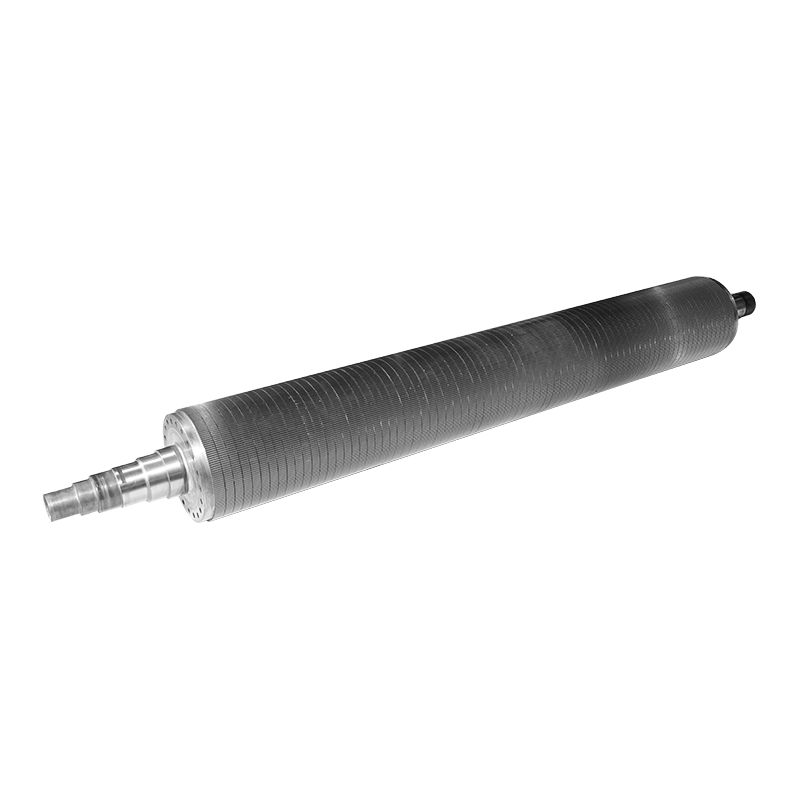

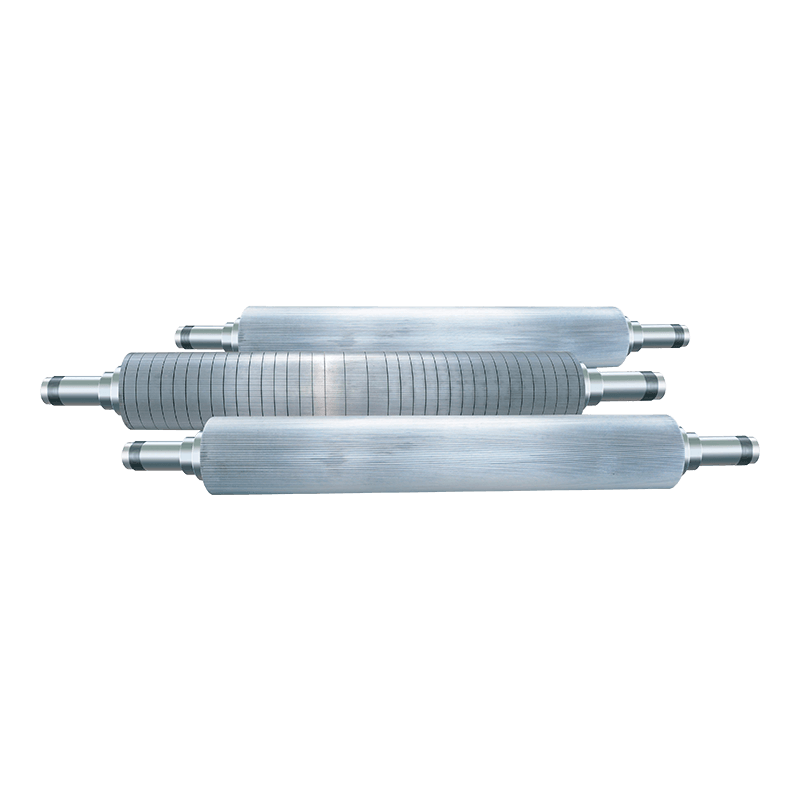

3. No Reverse Clearance Design: The angle wrap roll and angle swing roll are driven by a tension chain. The angle of the wrap can be adjusted according to humidity changes. Equipped with a floating roll, it maintains the stability of the base paper at high speeds;

4. Pressure Vessel Certification: The hot cylinder has passed the national pressure vessel inspection and comes with a national pressure vessel safety certificate;

5. Improved Paper Guide Design: Traditional preheating cylinders use gears to rotate the angle roll of the paper guide, which creates tension when the base paper passes through. There is always some gear clearance, causing the paper guide to shake up and down. The faster the speed, the more severe the shaking, to uneven base paper tension, increased noise and vibration of the corrugator, and unstable pasting. Our factory adopts a tensioned chain transmission design for the angle roll, eliminating these issues;

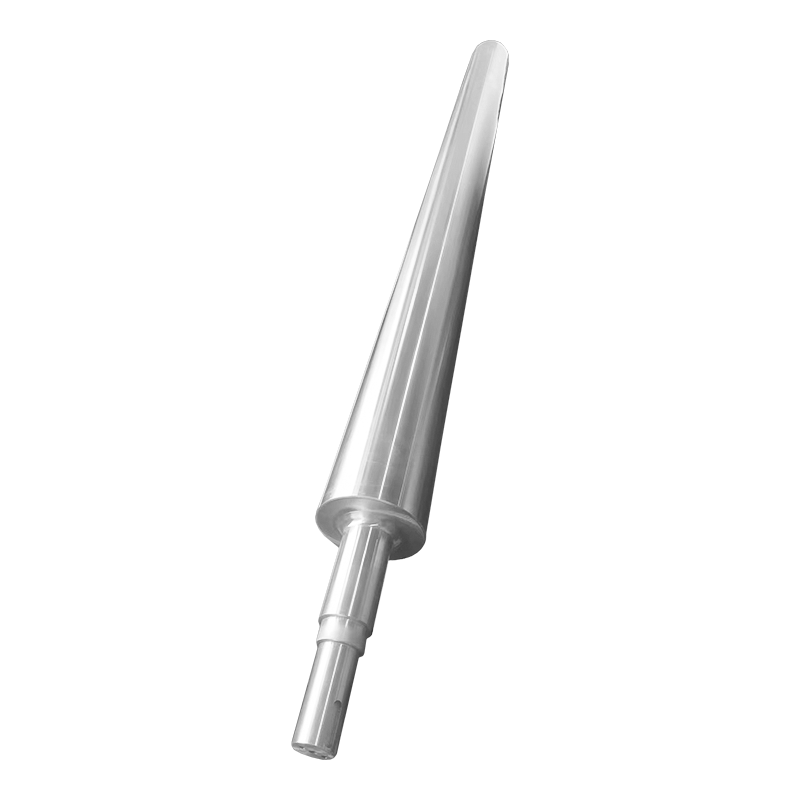

6. Steam Inlet and Drive Separation: The steam inlet and drive are separated for easier maintenance. The integrated design of the protection box and operation panel is both aesthetically pleasing and practical;

7. Peripheral Heating Technology: The cylinder block utilizes the latest peripheral heating technology;

8. Reduction Motor: Equipped with a high-quality reduction motor from Taiwan City State;

9. Servo Motor Drive: The angle motor is driven by a servo motor.

English

English  Español

Español  Português

Português  عربى

عربى