Product Features

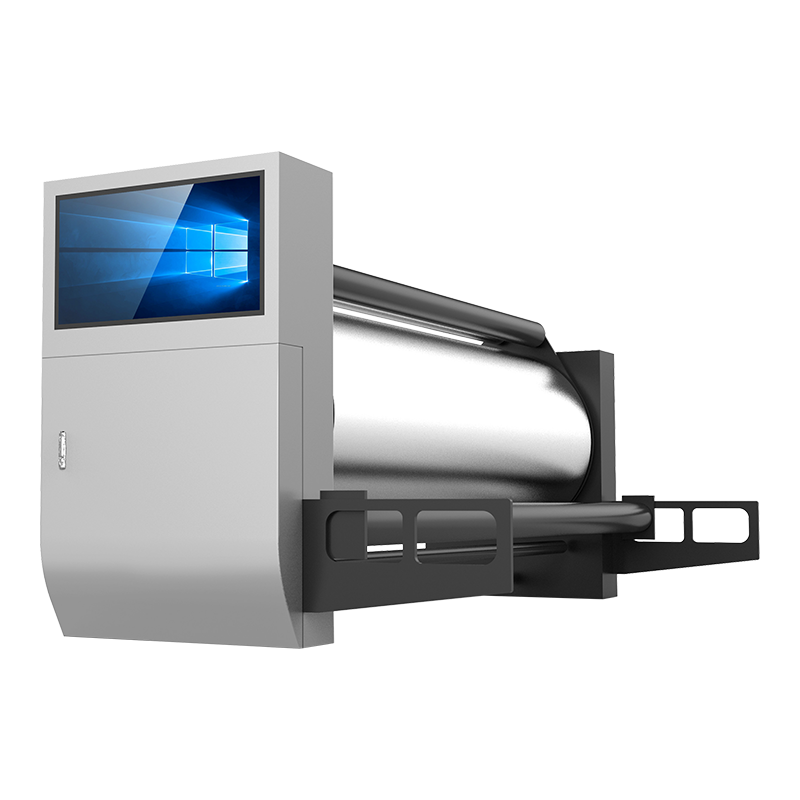

1. Hydraulic Lifting System for Hot Plate Section: The hot plate section features an automatically controlled hydraulic lifting system. Each set of pressure rolls is equipped with manual fine adjustment, and the cylinder is automatically upgraded for precise operation.

2. Automatic Canvas Rectifying Device: The top and bottom canvases are equipped with right/left automatic rectifying devices, controlled by bladder cylinders. These cylinders regulate the tension of the canvas belts to ensure stability during high-speed operation.

3. Steam Heating System with Independent Control: The steam heating system for the hot plates is divided into four groups, each with independent steam supply and water drainage. The temperature control valves for the last two groups can be cut off via a button on the operation console, eliminating the need for manual valve closure and improving efficiency. Additionally, the system adjusts the hot plates' surface temperature based on seasonal humidity variations, ensuring consistent cardboard flatness.

4. Robust Steel Frame Base: The base of the hot and cold plate sections is constructed with a durable 150H steel frame, ensuring the 20-meter double facer remains stable over long periods of use. This design prevents foundation subsidence and maintains the horizontal alignment of the hot plates.

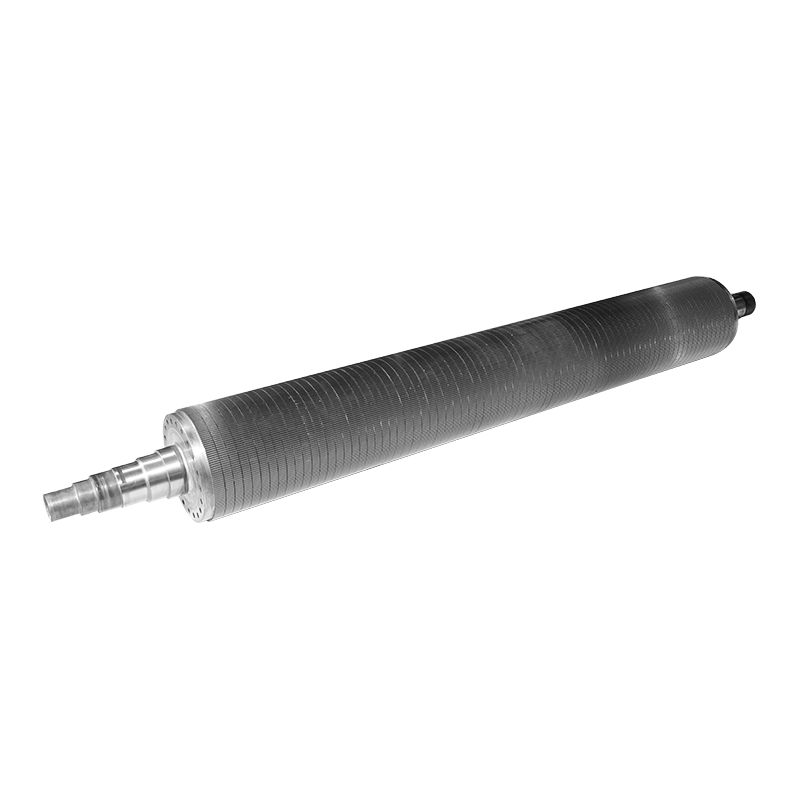

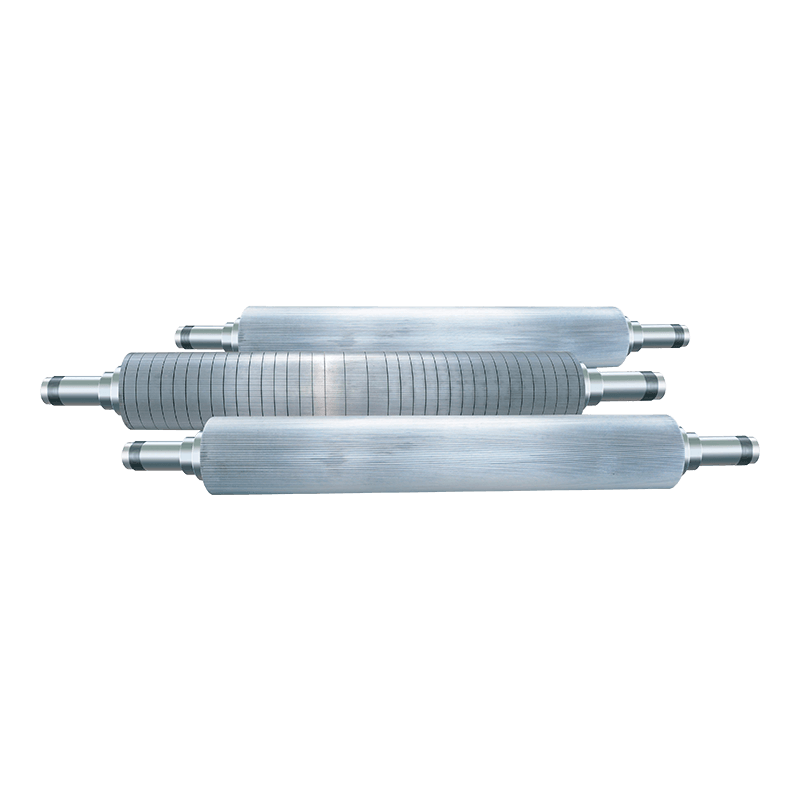

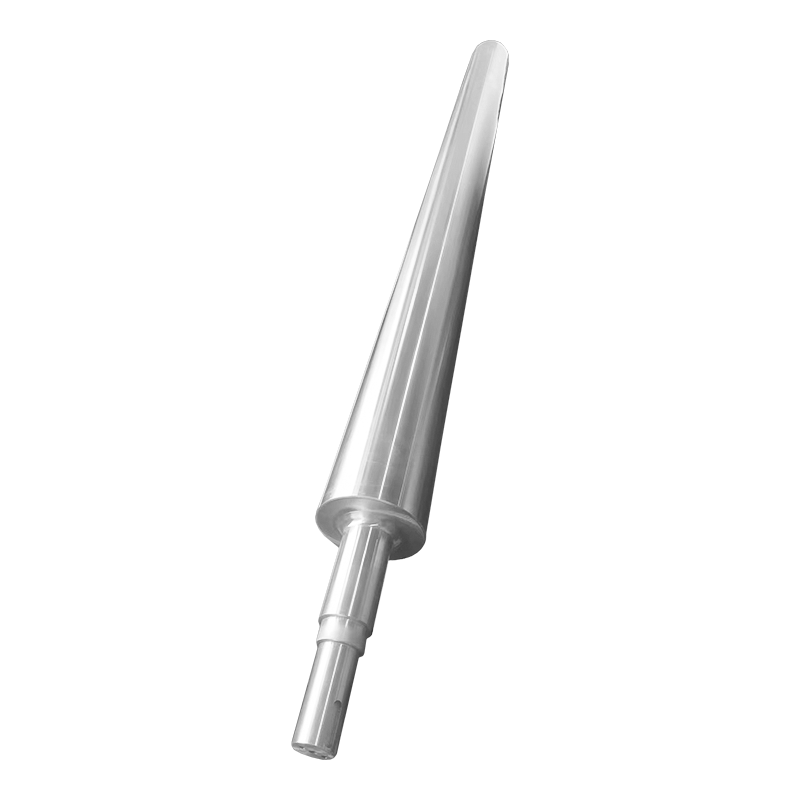

5. High-Quality Roller Mounting: The upper and lower rollers are securely fixed using mounting plates and imported bearings. The upper pressing roll is self-adjusting for High quality performance.

6. Adjustable Cooling Section Pressing Roller: The pressing roller in the cooling section is equipped with a liftable cylinder. When producing thin base paper or 3-ply cardboard, lifting the pressing roller prevents crushing the corrugates, reduces resistance, and saves electricity.

7. Three-Point Lock Design for Heating Plates: The heating plates feature a three-point lock design, significantly improving horizontal stability compared to traditional two-point lock systems.

8. Integrated Spray Nozzles: Spray nozzles are installed inside the heating plates. When producing 4-ply cardboard, activating the spray nozzles enhances line speed and improves pasting effectiveness.

English

English  Español

Español  Português

Português  عربى

عربى