Contact us

Focused on the R&D and manufacturing of high-quality corrugated rollers, the "heart" component of the corrugated cardboard production line.

+86-18661680180

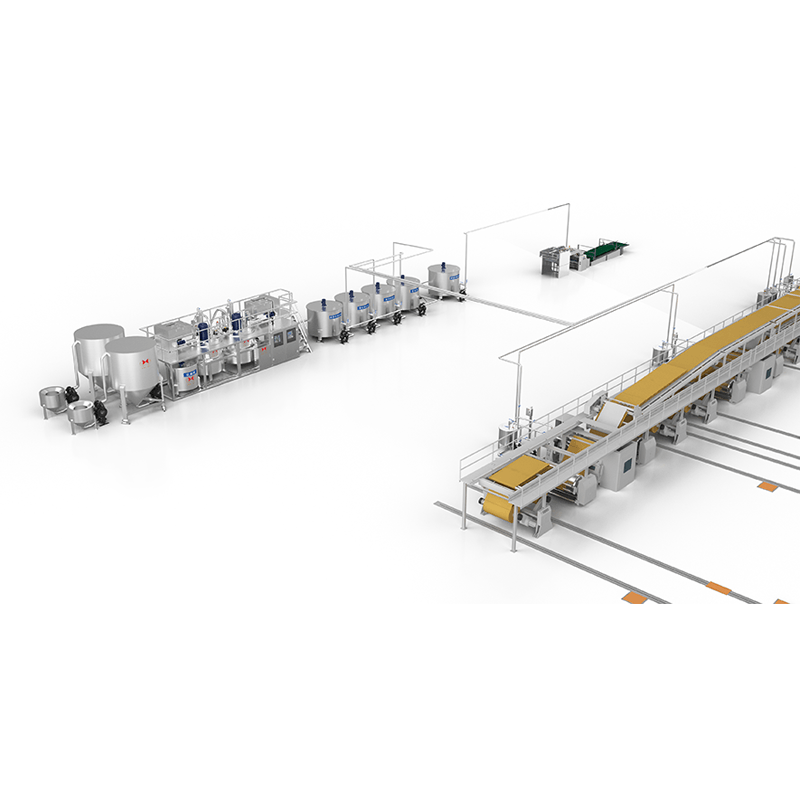

The corrugated cardboard line refers to the entire production system used to manufacture corrugated cardboard sheets and boxes. This line typically includes several machines, such as the corrugator, gluing machine, mill roll stand, and so on. Each machine plays a specific role in transforming raw materials like paper rolls into finished corrugated products. The process begins with the corrugator, which creates the fluted medium and bonds it to linerboards. The sheets then move through cutting, printing, and folding stages to produce customized boxes or sheets. Modern corrugated cardboard lines are highly automated, incorporating advanced technologies to improve speed, accuracy, and material efficiency. These systems are widely used in industries such as packaging, logistics, and manufacturing, where durable and lightweight packaging solutions are required.

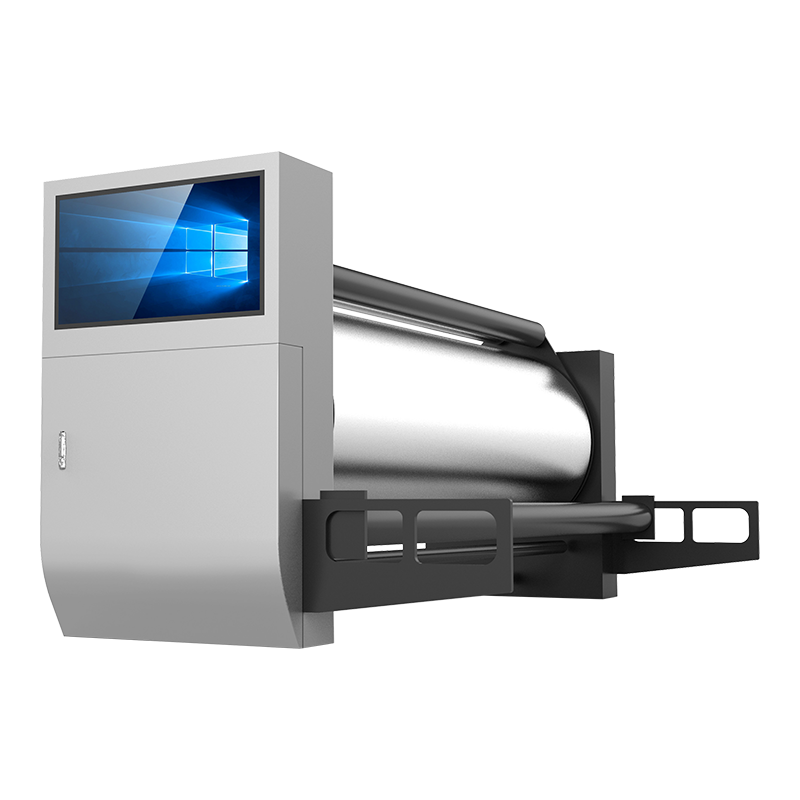

Hydraulic Vertical Forward Push Type Quick Change Roll Corrugating Machine

Fully Automatic Intelligent Redundant Dual System Glue Making Station

Enterprise establishment

Employees

A: A Corrugated Cardboard Line is an industrial production system designed to manufacture corrugated cardboard. This type of cardboard is made by gluing multiple layers of paper together, including a fluted corrugated sheet sandwiched between two flat linerboards, resulting in a material with outstanding compression resistance and protective properties. The production line encompasses various stages, from the input of raw paper to the output of finished products.

A: The main components of a Corrugated Cardboard Line include:

1. Single Facer: This is the starting part of the production line, responsible for bonding the fluted corrugated medium with a linerboard to create a single-faced corrugated board.

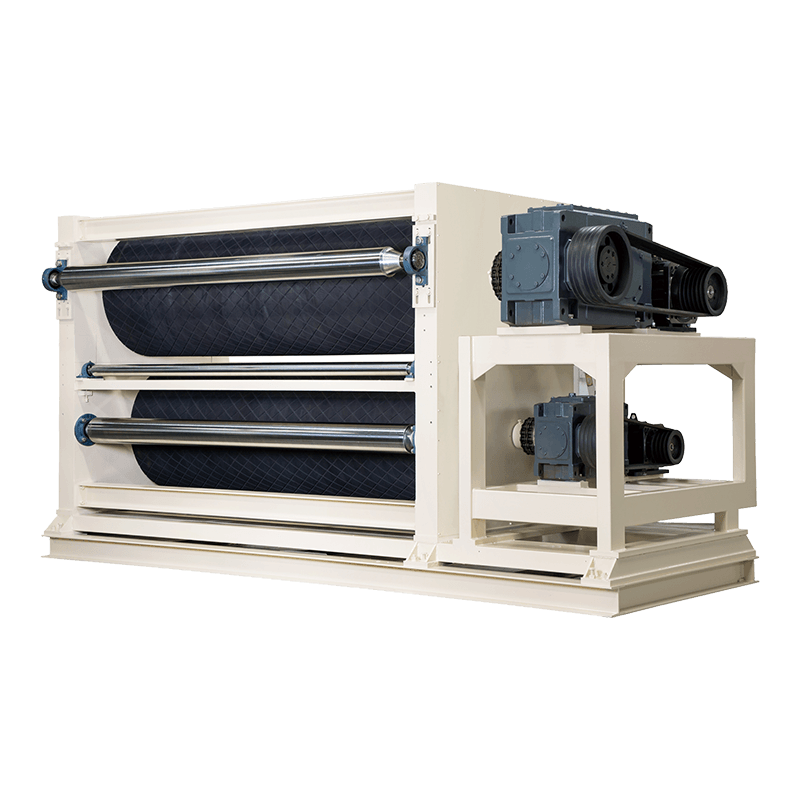

2. Corrugator: Used to process the corrugated medium into a fluted sheet with specific wave patterns.

3. Double Facer: Bonds another linerboard to the single-faced corrugated board to form a complete corrugated cardboard.

4. Cutting and Stacking System: Cuts the continuous corrugated cardboard into the desired sizes and stacks them.

5. Control System: Monitors the entire production process to ensure production efficiency and product quality.

A: Our Corrugated Cardboard Line offers the following advantages:

- High Efficiency: Our production lines incorporate advanced technologies that increase production speed and efficiency.

- Energy Saving: Designed with energy efficiency in mind, reducing operational costs.

- Flexibility: Capable of adapting to the production of corrugated cardboard of different sizes and types to meet diverse needs.

- Stability: Engineered for consistent performance, ensuring reliable production.

A: Our Single Facer is designed with the following key features:

- High-Speed Operation: Capable of operating at high speeds to increase production output.

- Precision Gluing: Ensures accurate adhesion of the corrugated medium to the linerboard for consistent quality.

- User-Friendly Interface: Features an intuitive control panel for ease of operation and adjustments.

- Reliability: Built with high-quality components to minimize downtime and maintenance.

A: Our Corrugator plays a crucial role in the production process with these contributions:

- Flute Profile Customization: Allows for the creation of various flute profiles to meet specific packaging requirements.

- Uniform Corrugation: Ensures uniform corrugation across the entire sheet for consistent quality.

- Durable Construction: Built to withstand the rigors of continuous operation in a production environment.

A: Potential users can expect the following advantages from our Corrugated Board Production Line:

- Cost-Effectiveness: By increasing production efficiency and reducing waste, our lines help lower overall production costs.

- Quality Control: Advanced control systems monitor quality metrics, ensuring that output meets or exceeds industry standards.

- Scalability: Designed to be scalable, allowing for expansion as your business grows.

- Technical Support: We provide comprehensive technical support and after-sales service to ensure your production line operates at peak performance.

A: Users can expect:

- Regular Maintenance: Scheduled maintenance programs to keep the production line in good condition.

- Quick Spare Parts Delivery: Access to a wide range of spare parts to minimize downtime.

- Technical Assistance: Available for troubleshooting and guidance on the operation of the production line.

- Training Programs: Offering training programs to help your staff operate and maintain the equipment effectively.

By choosing our Corrugated Cardboard Line, potential users can look forward to a robust, efficient, and reliable production solution that is backed by comprehensive support, ensuring a successful venture into corrugated cardboard manufacturing.