Introduction

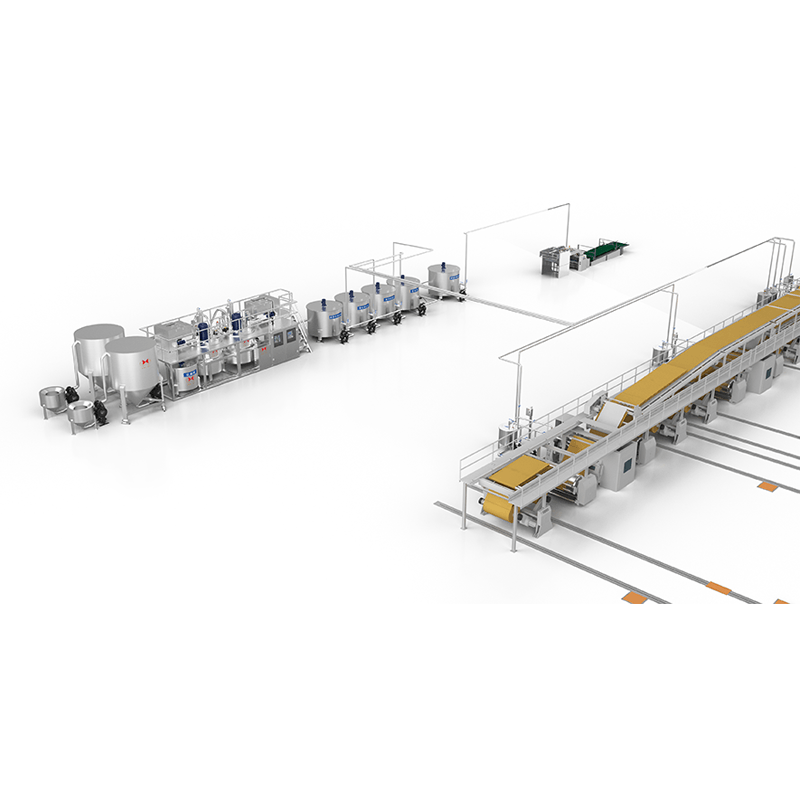

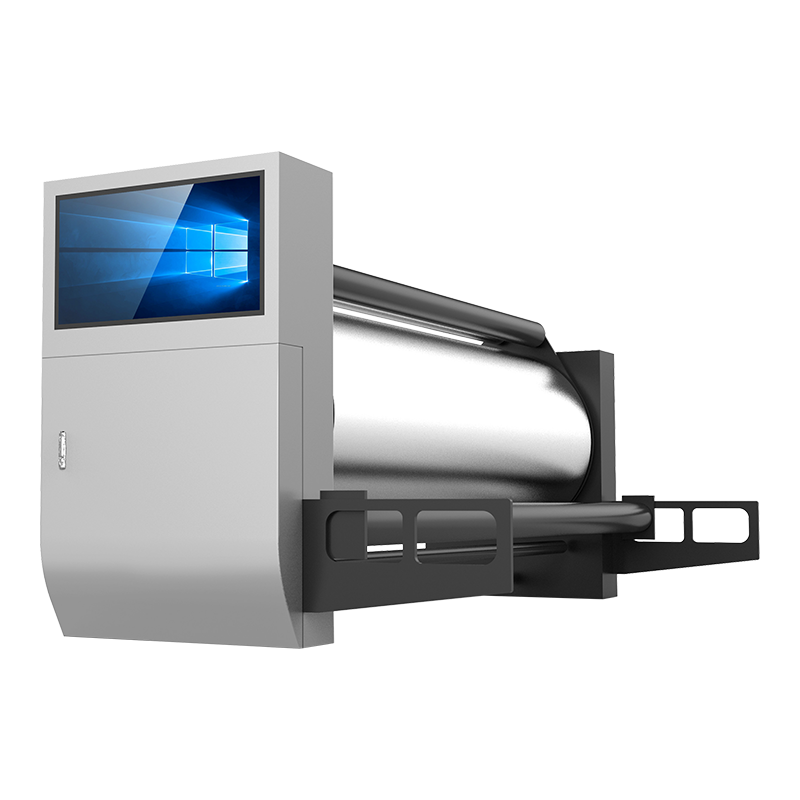

The Fully Automatic Intelligent Redundant Dual System Glue Making Station is a high quality solution designed for medium and large paper mills, ensuring uninterrupted glue production. This system features a double redundant design in both hardware and software, guaranteeing 24/7 operation without downtime. It supports remote diagnosis, upgrade, maintenance, and monitoring, allowing for seamless management through a LAN, mobile applet, or integrated production management system. The station is capable of meeting the high demands of multiple wide and high-speed tile lines, ensuring fast preparation of fresh, high-quality glue. Additionally, it includes intelligent data statistics for material and power consumption, precise glue usage metering, and online viscosity detection, making it a comprehensive solution for modern paper production needs.

Features

1. Redundant Dual-System Glue Production Station

Dual-System Redundancy: Guarantees continuous operation, eliminating production halts due to system failures.

Advanced Monitoring: Real-time oversight through multi-point LAN monitoring and mobile applet integration.

Data-Driven Insights: Tracks material and power consumption, machine glue supply, and glue usage with precision.

2. Intelligent Data Statistics Section

Comprehensive Reporting: Provides detailed material and power consumption reports for efficient resource management.

Precision Monitoring: Includes glue supply statistics, precise glue usage metering, and online viscosity detection.

Real-Time Optimization: Enables operators to monitor and adjust production processes for efficiency.

3. Environmental Protection and Energy Saving Features

Water Recycling: Reuses tile line washing machine water for glue production, significantly reducing water waste.

Maintenance-Free Design: Self-test and alarm functions ensure hassle-free operation.

Remote Maintenance: Intelligent diagnostics allow quick issue resolution, regardless of distance.

Fool-Proof System: Prevents errors and ensures safe, reliable operation.

4. Customized Glue Making Processes

Flexible Options: Offers one-step, two-step, mounting, modified starch, synthetic powder, and three-in-one glue making processes.

Precision Control: Allows arbitrary combination of gum making modes and formulas for tailored production needs.

Custom Storage Solutions: Provides starch storage tanks tailored to specific factory requirements.

5. Remote Monitoring and Maintenance

Online Upgrades: Enables system updates and improvements via internet access.

Real-Time Diagnostics: Quickly identifies and resolves issues through remote diagnostics and PLC connectivity.

Cost Savings: Reduces the need for on-site after-sales service, saving time and expenses.

Comprehensive Alarms: Includes logical, component feedback, mis-operation, material shortage, viscosity, temperature, power, and motor overload alarms.

English

English  Español

Español  Português

Português  عربى

عربى