More Information About Intelligent Automatic Glue Making Machine System What You Need To Know

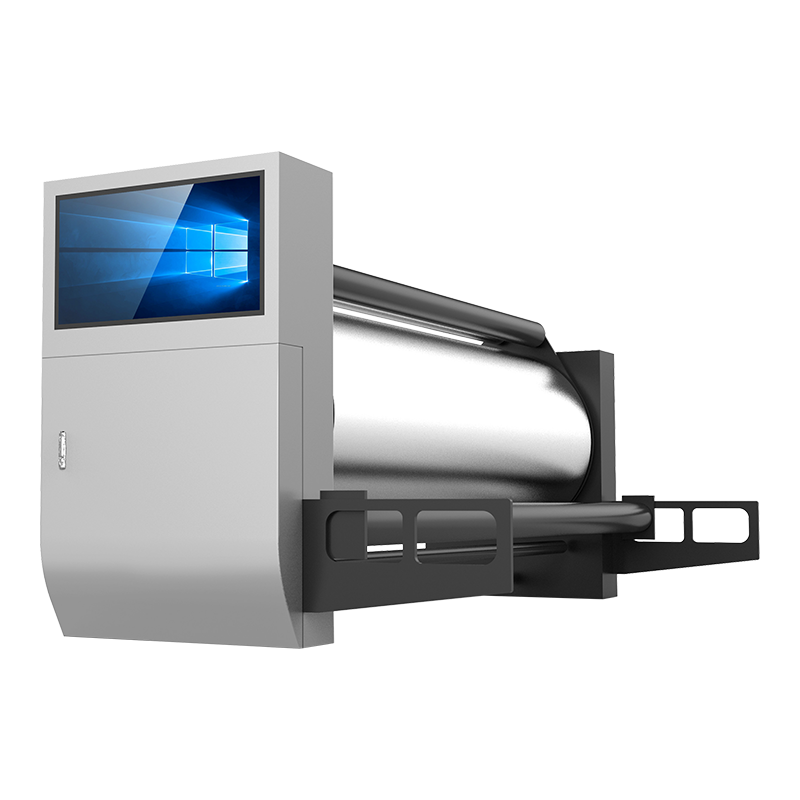

At Zhejiang Yonghui, we are proud to introduce our Intelligent Automatic Glue Making Machine System, an innovative solution designed to meet the growing demands of the corrugated cardboard industry. Our glue making machine is engineered to automate and optimize the glue production process, offering significant advantages in efficiency, consistency, and cost-effectiveness. This system is essential for manufacturers looking for high-quality adhesive solutions in large-scale production environments, whether for paper glue machine applications or glue stick making machine needs.

What Is the Intelligent Automatic Glue Making Machine System?

The Intelligent Automatic Glue Making Machine System is a fully automated solution designed to produce glue efficiently for corrugated board manufacturing. The machine integrates advanced technology with intelligent control systems to mix, prepare, and dispense glue at high speed and precision. With the increasing demand for fast and reliable adhesive production, this system eliminates manual labor, reduces human error, and enhances productivity.

This system is ideal for businesses in the packaging and paper industry that need a continuous supply of glue, especially in high-volume environments. Whether it's for small or large-scale operations, the glue making machine ensures consistent and high-quality adhesive, making it a vital component of any corrugated cardboard production line.

Key Features of the Intelligent Automatic Glue Making Machine

1. Automatic Glue Production

Our glue making machine automates the entire glue production process, eliminating the need for manual preparation and mixing. The system monitors and adjusts the glue formulation in real-time, ensuring consistent quality throughout the production cycle. This is particularly beneficial for manufacturers who require large quantities of glue in a short amount of time.

2. Precise Glue Mixing and Consistency

The machine is equipped with advanced mixing technology to ensure that the glue is mixed evenly, providing a high-quality product. Consistent viscosity and texture are critical in paper glue machine applications, and our system guarantees that the adhesive meets the precise standards needed for successful corrugating.

3. Energy Efficiency

In addition to reducing labor costs, the Intelligent Automatic Glue Making Machine System is designed with energy efficiency in mind. It minimizes glue waste and optimizes energy use, providing a cost-effective solution for businesses looking to reduce their operational expenses while maintaining high production standards.

4. High-Volume Output

Designed for high-speed production lines, the system can handle large volumes of glue without compromising on quality. It continuously delivers the required amount of adhesive, ensuring that production runs smoothly without interruptions. This is especially valuable for manufacturers of glue stick making machines, where continuous glue supply is essential.

Applications of the Glue Making Machine System

The Intelligent Automatic Glue Making Machine System is primarily used in the corrugated cardboard industry but has versatile applications in other sectors as well:

Corrugated Cardboard Production: As one of the key components in the corrugating process, this paper glue machine produces the high-quality adhesive required for bonding the liner and medium in corrugated board production.

Packaging Industry: Businesses involved in packaging rely on the glue stick making machine to maintain a steady supply of glue for their production lines. The glue making machine ensures that the glue is consistently prepared, meeting the demands of large-scale packaging production.

Paper and Printing: The system can also be used in the paper industry for adhesive applications in paper laminating or binding, providing a reliable solution for businesses that require high-quality, uniform glue preparation.

Advantages for Manufacturers and Users

1. Improved Operational Efficiency

By automating the glue-making process, the Intelligent Automatic Glue Making Machine System eliminates bottlenecks caused by manual preparation. This significantly speeds up the production process, allowing manufacturers to meet high production demands without compromising on quality.

2. Reduced Labor Costs

With the automation of glue production, businesses can reduce the number of labor-intensive tasks, cutting down on manpower and associated costs. Additionally, the system reduces human errors, ensuring that glue quality remains consistent across production runs.

3. Minimal Maintenance and Downtime

The system is designed to be easy to maintain, with clear diagnostics and self-regulating mechanisms. It requires minimal intervention, reducing downtime and maintenance costs while keeping your production line running smoothly.

4. Customizable Glue Formulation

The glue making machine allows manufacturers to adjust the formulation based on specific product requirements. This flexibility ensures that businesses can produce various types of glue with different viscosities, strengths, and other properties that match their needs.

English

English  Español

Español  Português

Português  عربى

عربى