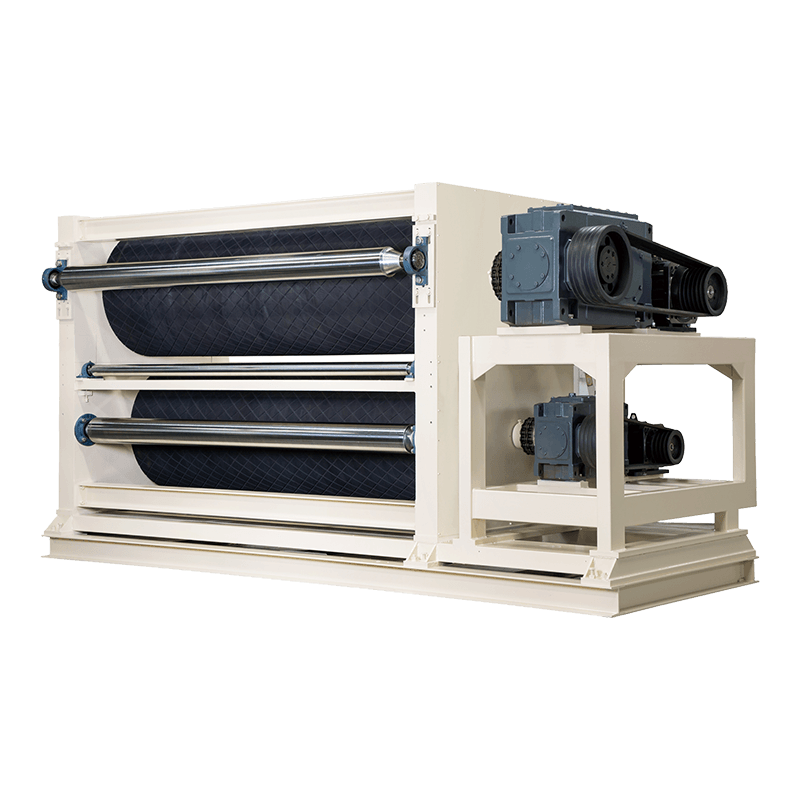

Product Features

1. Layered Independent Motor Drive: Utilizes a scattered-tooth gearbox, saving over 20% more electricity compared to traditional gearboxes.

2. Consistent Resistance Management: Prevents inconsistent resistance between the upper and lower belts, avoiding skidding on the rubber roller of the drive wheel and ensuring synchronization between the top and bottom belts, even as the canvas belt ages.

3. Independent Belt Replacement: In traditional double facers, both the top and bottom belts must be replaced simultaneously. However, often the bottom belt remains in good condition while the top belt wears out. With our master drive, the layered independent motor system allows for the replacement of only the top belt, eliminating the need to replace the bottom belt unnecessarily.

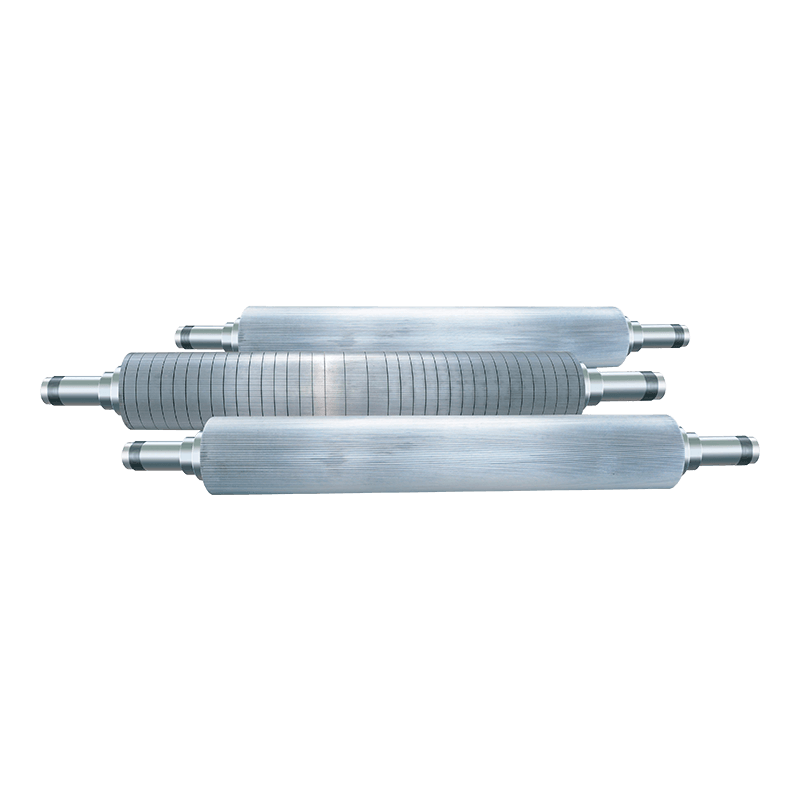

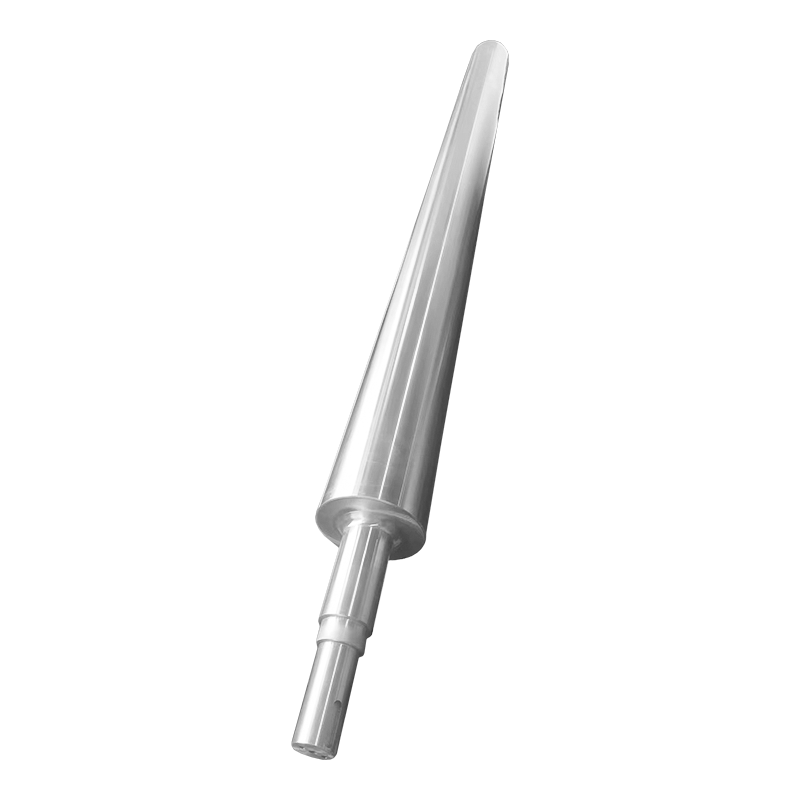

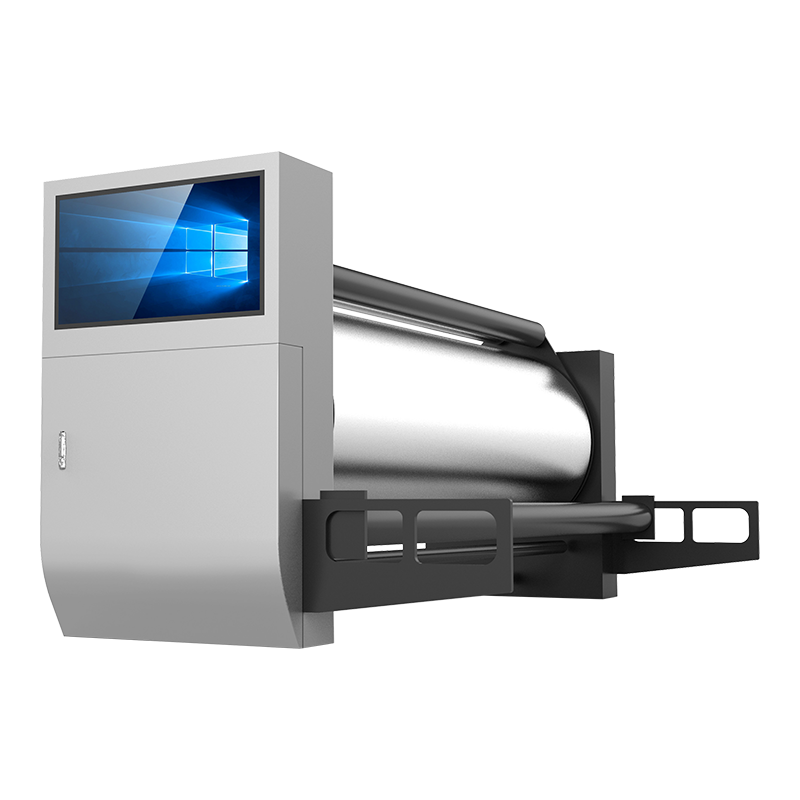

4. Optimized Roller Design: Both the top and bottom rollers have a diameter of Φ910mm and are set at a medium-high level. They are covered with durable, rhombus-patterned rubber for enhanced wear resistance.

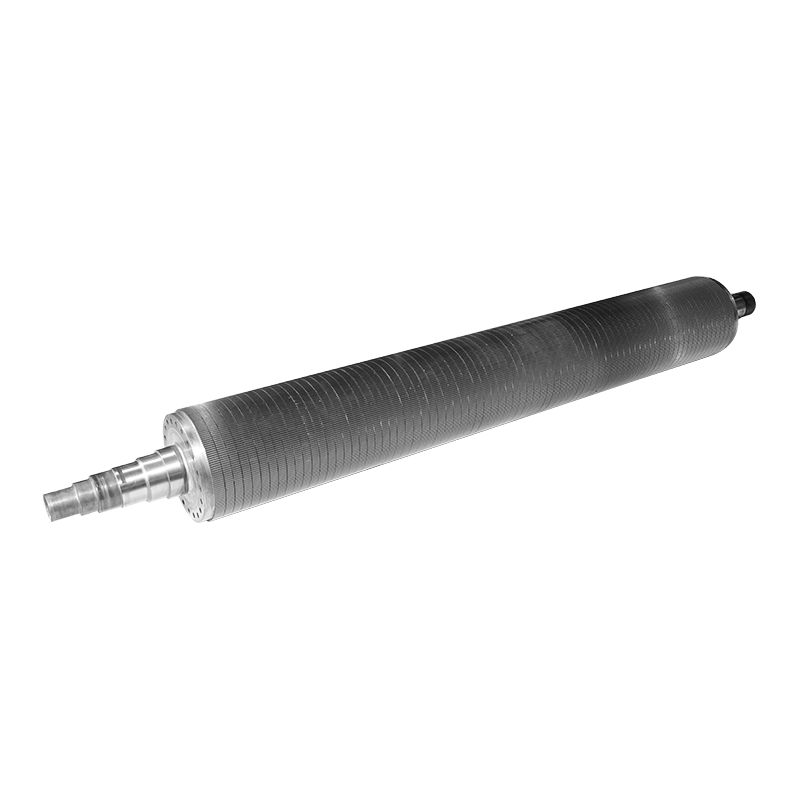

5. Canvas Belt Guiding Roll: Our unique design features a guiding roll that adjusts to compensate for canvas belt wear. By increasing the friction between the canvas belt and the rubber roller's wrap angle, this design maximizes the service life of the canvas belt.

6. Fast Braking System: Achieves a full stop in just 2 seconds, even when the hot plates are operating at speeds of 120m/min. This not only reduces waste but also saves electricity. The system is compatible with production lines operating at speeds ranging from 150m/min to 300m/min.

English

English  Español

Español  Português

Português  عربى

عربى