Introduction

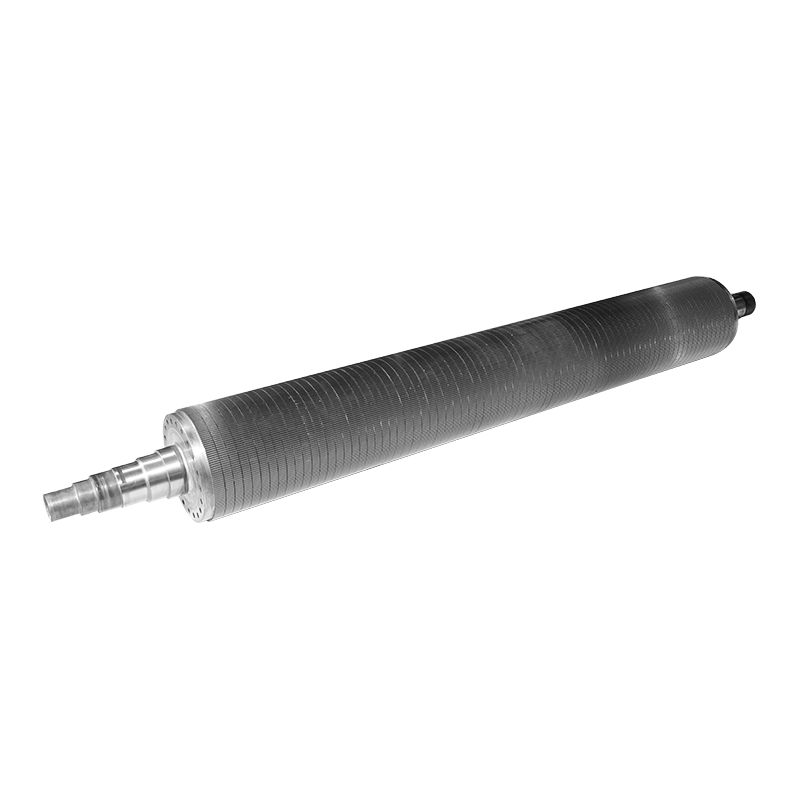

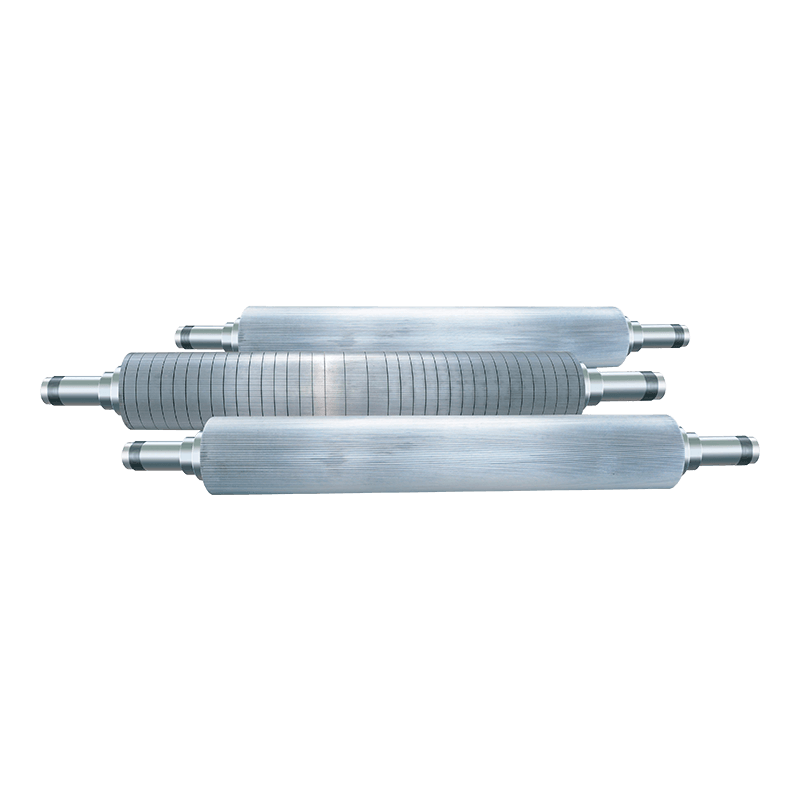

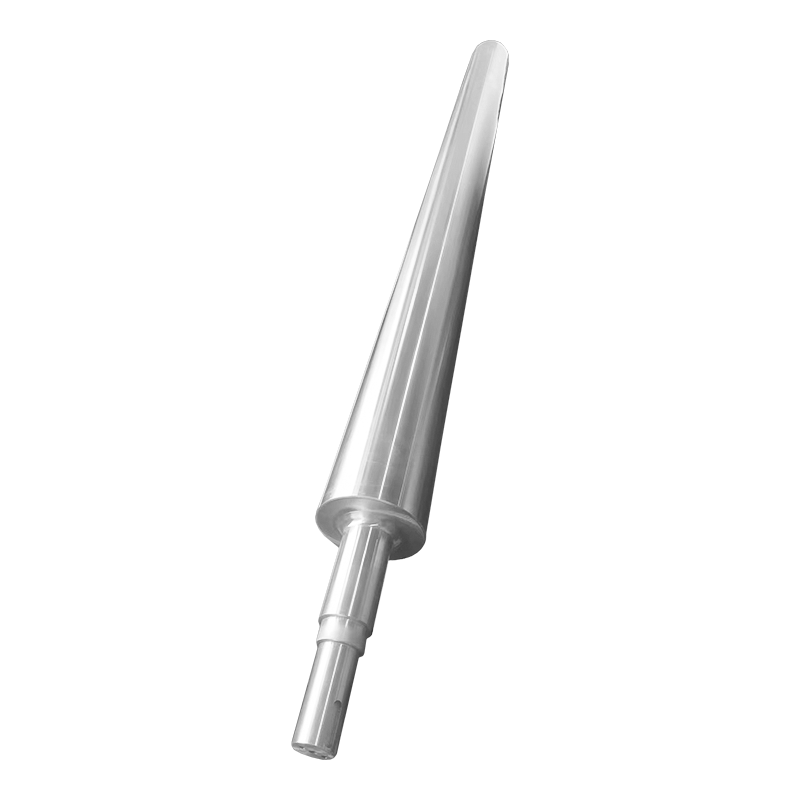

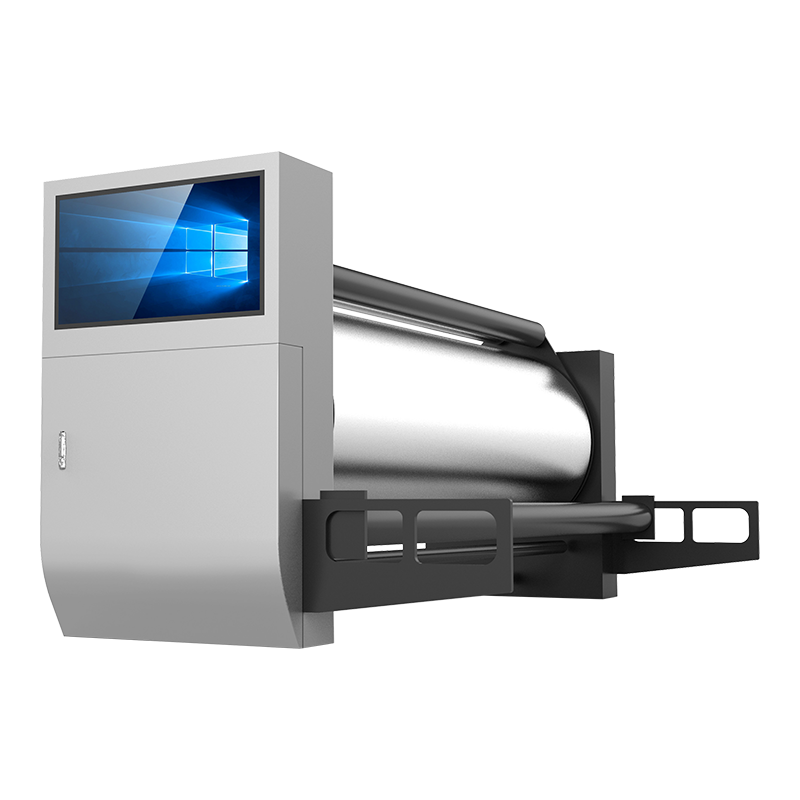

The Corrugated Carton Machine Slotter Knife is a high-performance tool designed for precise slotting and cutting of corrugated cartons. It plays a crucial role in the production of corrugated boxes, providing clean cuts and enhancing overall productivity. The knife features a special fillet edge and a movable tip, made from high-speed steel (SKH) inlaid into advanced metal materials. These innovations help reduce burrs, prevent breakage, and improve durability, making it ideal for use in high-speed, automated carton production lines.

Materials Used

The blades are made from premium materials such as SKD11, D2, and SKH-9 steel, known for their high quality wear resistance, toughness, and ability to maintain a sharp edge for extended periods of use.

Five Types

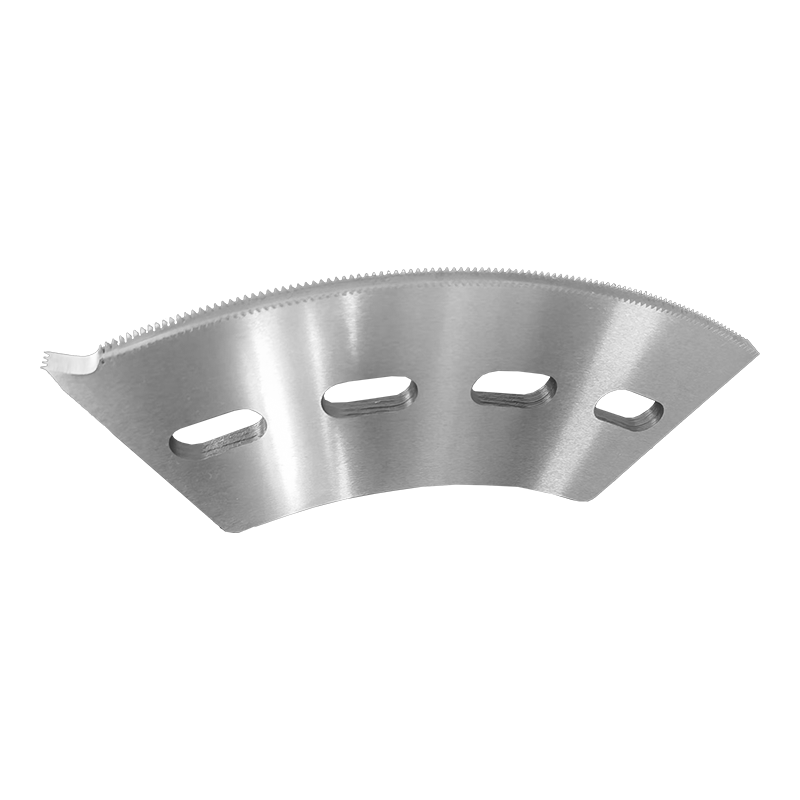

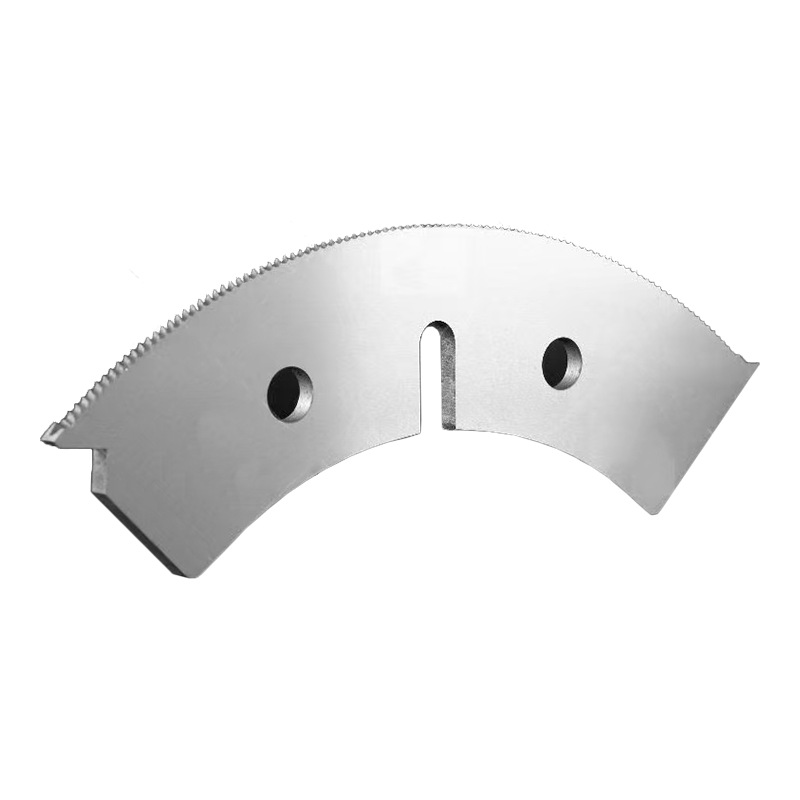

1. Top Notch Cutter: This knife is used to create the top notch in the carton, ensuring smooth and precise cuts. Its design allows for high efficiency and minimal maintenance.

2. Lower Slotted Knife: Designed for the lower part of the slotting process, this knife provides consistent, clean cuts with a high level of precision.

3. Carton Trimmer Knives: These knives are specialized for trimming the edges of corrugated cartons, delivering a polished, burr-free finish.

4. Corner Cutter Station: This type of knife is used for cutting the corners of the carton, offering sharp, precise angles for clean, uniform edges.

5. Washer (Spacer): This component is used in conjunction with the other knives to adjust and maintain the proper spacing between blades, ensuring High quality cutting performance.

English

English  Español

Español  Português

Português  عربى

عربى